Understanding Robots Automation: A Comprehensive Guide

Key Highlights

- Robot automation integrates robotics, automation, and artificial intelligence to streamline business processes.

- It increases efficiency, enhances operational accuracy, and reduces the time spent on repetitive tasks.

- Robotics and automation offer distinct but complementary functionalities, supported by core technologies such as sensors, machine learning, and computer vision.

- Industries like manufacturing, healthcare, and the service sector benefit significantly from robotic process automation (RPA).

- Though promising, implementing robot automation involves overcoming challenges such as legacy systems and scaling issues.

- Future trends focus on cognitive automation and expanded use of AI, reshaping how industries function.

Introduction

The use of robotics and automation has changed many industries. They use smart tools called artificial intelligence to help with this change. Now, companies can set up new ways to work. This means less manual work for people, and tasks happen more easily.

When robotics works with automation, the two make jobs faster and more accurate. Artificial intelligence, or AI, brings smart ideas into the mix. We see this change everywhere. For example, you can see it in large factories and in healthcare.

Together, robotics, automation, and AI help companies handle routine tasks. They can cut down on costs and help with digital transformation. This is a big part of how a modern production environment works today. Workflows get better, and jobs are done in a new way that fits today’s world.

Robot automation is when you use robotic automation tools along with smart systems to do set jobs in a fast and steady way. These tools use AI and an automation process to take care of repetitive tasks without mistakes. The move to this way of working helps cokmpanies grow and work faster than old methods.

Intelligent automation takes robotic automation further. It mixes clear workflows with smart learning skills. When you use tools like intelligent document processing and real-time decisions, your options get a lot bigger. This progress helps businesses stay ahead in a world where automation is growing fast.

Difference Between Robotics and Automation

Robotics and automation are two different things in the industrial world, even though some people use the words in place of each other. Robotics is about making machines that copy what people do. Automation, on the other hand, is about using technology to make steps in a process go faster and need less help from people. These two areas can come together to help make work more smooth and quick, but the way they work is not the same.

For example, robotics is about real machines, like robotic arms, that you can see in factory automation. These machines can do jobs that require movement and strength. Automation is mostly about using software. Tools like robotic process automation (RPA) help take care of office jobs and make them easier. With process automation, many things happen without anyone needing to step in.

There is a big difference in the way they both depend on human intelligence. Robotics may still need a person to set things up or fix things when they go wrong. Automation usually works by following a clear set of rules, so it can run on its own. When robotics and automation work together, they can make systems that are more flexible and ready to change as new needs come up. This mix can be used in many types of industries and often leads to better results for everyone.

Types of Robots Used in Automation

Robot automation uses many kinds of robots, with each type built to do a different job. Here are the main types you will see the most:

- Industrial robots: These are found in factory automation and do things like welding, putting parts together, and making things.

- Collaborative robots (cobots): These work with people, taking on jobs that need flexibility and precision.

- Autonomous mobile robots (AMRs): These help out in warehouses and when moving things for supply chains, like picking items and carrying them.

- Specialized robots: These work in certain fields, such as

aerospace and

healthcare.

The {{use of robots}}, whether they are on an assembly line or working in a control room, helps make workflows better. Their flexibility makes them good at helping people, especially with jobs that need a lot of careful work and repeat actions. Because of this, flexible automation has grown, letting these robotic solutions meet the new needs of modern businesses.

How Robot Automation Works in Modern Industries

Robot automation uses automation technology and programmable systems to make work better and faster. With the help of automation systems, jobs that are done again and again, or by hand, are now done by machines. This helps to raise the level of work and saves time.

In a production environment, both robots and other smart machines are set up to handle different tasks and new work stages with care. This makes sure every job is done right. When businesses use data and smarter systems, they get better at their tasks, from being more careful with their work to being able to handle more. This shows how important robotics is for today’s industries and growth.

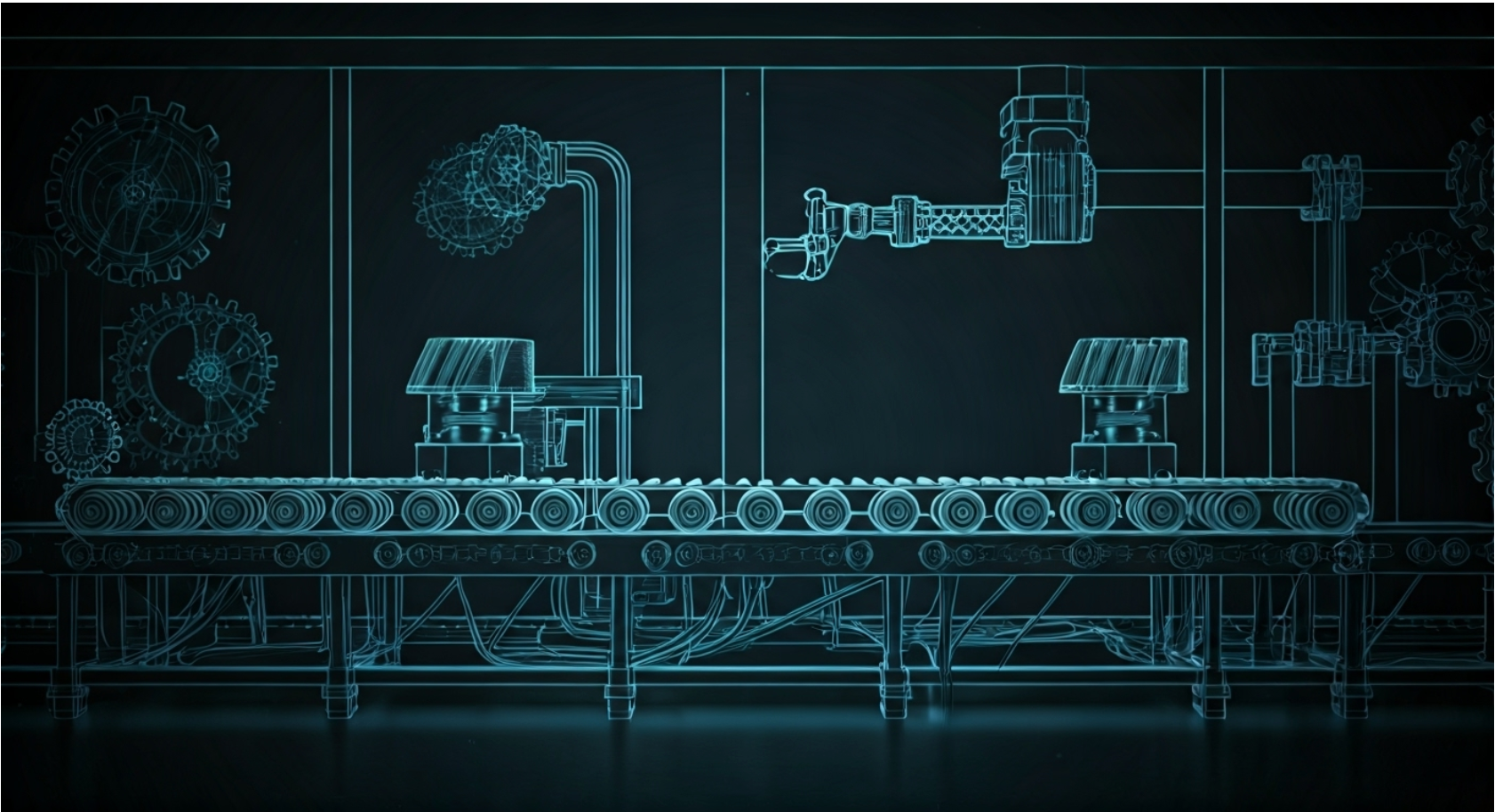

Core Technologies Enabling Robot Automation

Core technologies like sensors, computer vision, and machine learning are important for robot automation. Here’s a look at what each does:

| Technology | Functionality |

|---|---|

| Sensors | Detect things in the environment, like temperature, light, and movement. |

| Computer Vision | Helps robots see and understand what is in front of them by using visual data. |

| Machine Learning | Lets robots learn, change, and get better as time goes on. |

All these technologies work together well to make automation systems that can move around in changing places. For example, sensors keep track of workflows, computer vision checks and sorts objects, and machine learning makes choices. When put together, these help automation systems work on their own and be more correct, which is important for today's industries.

Integration of Robots with Digital Systems

Modern businesses do well when they use digital transformation and bring in automation systems. The use of APIs lets robots connect easily with business systems. This helps make business process automation work better in areas like finance and operations.

For example, automation systems and robots can get jobs done and keep information safe and correct. Bringing everything together makes it easy for robots to work with old and new digital setups. In RPA, robots use the usual screens and do not change how the back-end works. This means process automation can be done without disruption.

Companies that start using these automation systems get better teamwork, are more flexible, and have better ways to look at their data. With robotic power and digital ways, they build smart workflows that can grow as needed.

Major Applications of Robot Automation Across Sectors

The use cases of robot automation are found in many industries. You can see the effect in lots of different jobs. Robots help make process automation better in places like manufacturing and healthcare. They can do simple jobs, but they also help with tough work.

Automation makes work faster. It can handle money tasks, watch over supply chains, and pull details from messy documents. In retail, robots help to make sure orders are right. They help spot fraud, too. By dealing with the problems that each sector faces, businesses use automation to make their workflows better and easier.

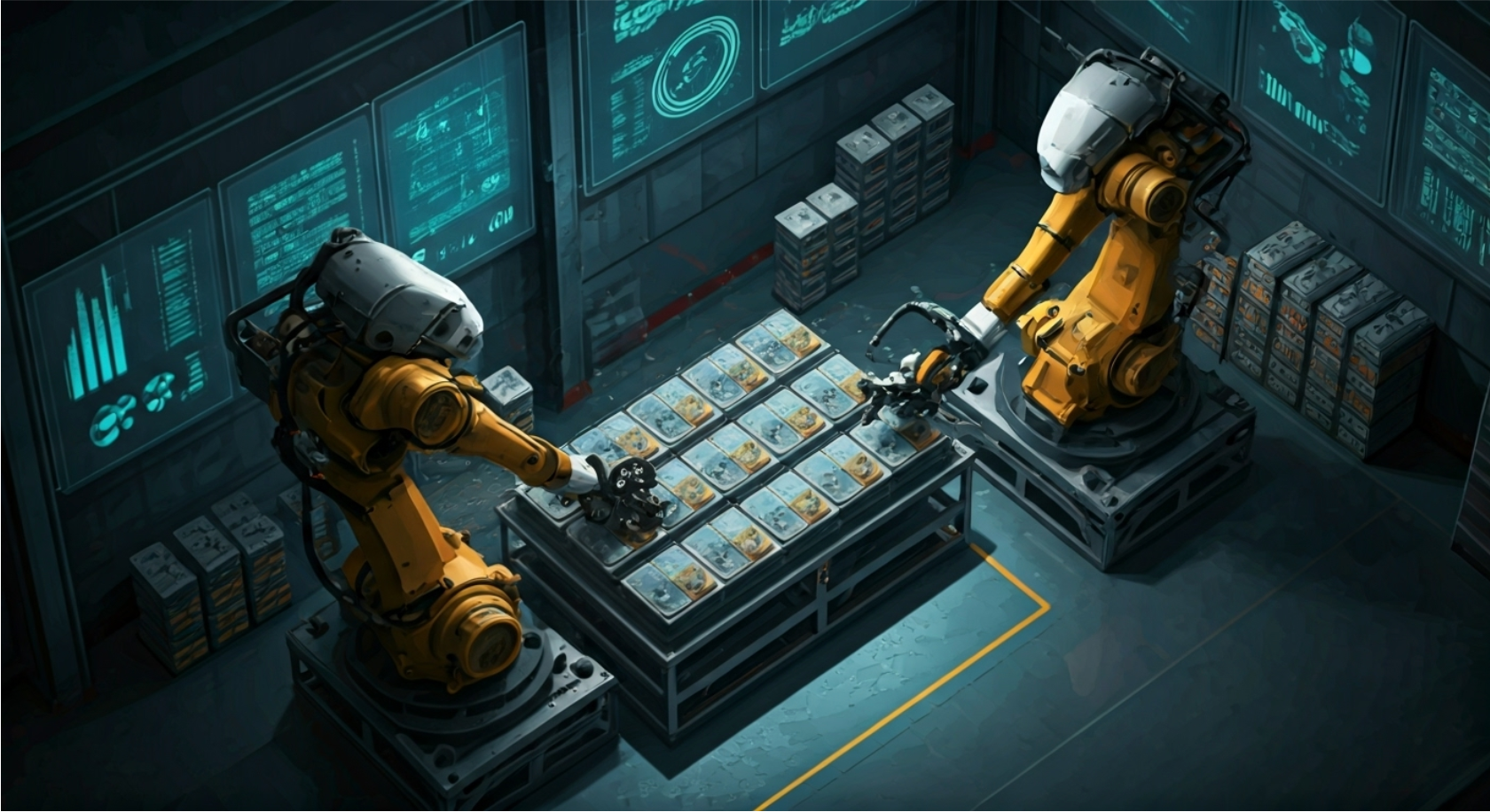

Manufacturing and Industrial Use Cases

Robot automation is speeding up progress in the manufacturing world. It helps people do their jobs with more precision and higher productivity. The most common ways that companies now use automation are:

- Warehouse automation helps manage inventory in the right way.

- Production environment tasks, like putting things together and packaging them, are done by robots.

- Robots move materials from place to place. This improves how things get from one area to another.

- They also raise operational efficiency by using checks for quality and keeping machines working before they break.

By bringing in automation, there is less need for people to do simple, repetitive jobs. This lets everyone focus on more advanced tasks. Using robots leads to fewer mistakes, faster work, and lower costs. This makes the business model both efficient and easy to grow over time.

Service Industry and Healthcare Applications

The service and healthcare fields are using more robot automation to make things more reliable and efficient. In healthcare, automation helps the people who work there with medical records, taking care of prescriptions, and processing claims. This makes sure that everything is done the right way, on time, and it helps improve how patients are cared for.

In the service field, robots do things like answer customer questions and book appointments. This helps improve employee satisfaction and the way people are treated up front. Bots talk to clients in chats and set up appointments, so the experience for clients and employees is smooth and easy.

With automation and robotics, those working in healthcare and people in service jobs have more time for tasks that add value. Robots take on the more repetitive tasks so professionals can focus on what really matters at work.

Benefits and Challenges of Robot Automation

Robot automation brings many unique benefits. It offers more positive effects on how workflows go. It can help save money and improve precision. This technology can take over simple and repetitive tasks so people can focus on more important strategy work.

But there are still some challenges. It can be hard to use with old legacy systems, and some disruptions may happen during the change. Still, with good planning and solutions made for the company, these problems can be handled. That way, companies can get the most out of automation technology, showing how this automation can change the way we work in the best way.

Increased Efficiency and Cost Savings

Robot automation brings big changes to many industries. It helps the workplace run better. Automated systems do repetitive tasks in less time and with better precision. This helps use resources in the best way.

Businesses can save a lot of money by cutting down on errors and daily costs. For example, RPA bots can sort many invoices quickly. This means people have to do less work, and it also helps companies get better results for their time and effort.

When you use robotic automation, precision gets better and your workflows keep moving without stopping. Bots make tasks easier and let businesses do more and grow in a way that does not cost too much. Automation makes it possible for companies to run smoother and reach new goals.

Common Obstacles and How to Overcome Them

Adopting automation often means you have to face some problems. Some of these are working with old legacy systems, dealing with a small budget, or trying to make your project bigger. Systems that were made many years ago may not work well right away with new rpa implementations. This can cause small problems when you link them up.

To fix these issues, you need good planning, the right tools, and training for your team. Using ai-based insights, companies can see what the gaps are. They can then change robots for what the automation process needs right now.

When you make clear plans that match your automation goals, your company can face these challenges in a better way. You can do this without any big disruption to projects that help your company grow.

Future Trends in Robot Automation

The future of robotic automation will use more AI, cognitive automation, and NLP. These tools help predict what will happen in a process. They also learn about new workflows and find ways to deal with challenges as they come up.

Now, businesses focus on systems that give real results. Robotic process automation keeps getting better. This means it will use more intelligent tools that can handle the full process from start to finish. These new trends help companies stay quick and ready for any new needs in the industry. This way, process automation, AI, and cognitive automation can all work together in some new ways.

Artificial Intelligence and Machine Learning in Robotics

AI and machine learning are changing robotics in big ways. These tools help with finding patterns, making robots more flexible, and helping them make better choices. Natural language processing (NLP) lets robots understand what people want to say.

When people give machines lots of data, machine learning helps robots work on their own. For example, some systems can sort medical records fast. This helps hospitals work better.

As AI gives more smarts to robotics, companies get a useful tool that works with automation systems made for the future. With so many new ideas every day, the ways to use AI in robotics just keep growing.

Conclusion

To sum up, robot automation is changing the way industries work. It helps increase how fast jobs get done and brings down running costs. When you understand the most important ideas, tech, and uses of robot automation, your business can use these tools in a better way. Joining robots to digital systems can give you more ways to make things better and new. It is a good idea to know about the problems that may come, so your company is ready to deal with them. The world is seeing more use of artificial intelligence and machine learning every year. Keeping up with the latest automation trends will help your business stay ahead. If you want to see what robot automation can do for you, reach out to us today for a free talk!

What are the key benefits of implementing robots in automation?

Implementing robots in automation offers numerous benefits, including increased efficiency, reduced labor costs, and enhanced precision. Robots can operate continuously without fatigue, improving production rates while minimizing human error. Additionally, they allow for safer work environments by handling hazardous tasks, leading to better overall workplace safety and productivity.