Difference between HMI and PLC

HMI (Human-Machine Interface) and PLC (Programmable Logic Controller) are two key components of industrial automation systems, often used together to control and monitor industrial processes. They serve different but complementary roles in the automation hierarchy. Here's a breakdown of their differences:

Function and Purpose:

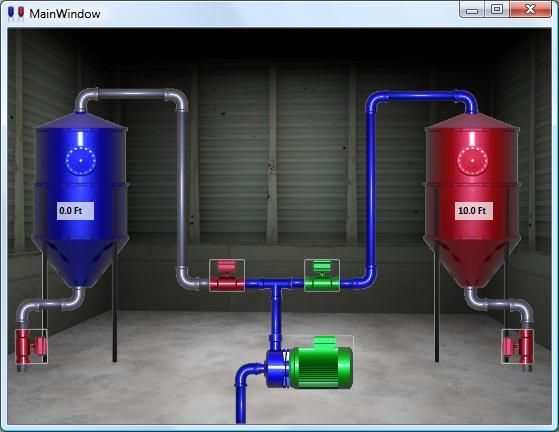

HMI (Human-Machine Interface): An HMI is a user interface that allows operators and engineers to interact with industrial processes and equipment. It provides visual representations of the processes, real-time data visualization, alarms, and control options. HMIs are used to monitor process status, control parameters, and make adjustments as needed.

PLC (Programmable Logic Controller): A PLC is a hardware device used to control and automate industrial processes. It's a ruggedized computer that executes logic based on programmed instructions to control machinery, equipment, and processes. PLCs are responsible for carrying out control tasks, reading input data, executing programmed logic, and generating output signals.

Hardware vs. Software:

HMI: An HMI can be both hardware and software. The hardware part consists of the physical interface devices like touchscreens, buttons, and indicators. The software part includes the graphical user interface (GUI) that presents data, alarms, and controls to the user.

PLC: A PLC is a dedicated hardware device. It consists of a processor unit, input/output (I/O) modules to interface with sensors and actuators, and communication modules for data exchange.

Role in Automation:

HMI: The primary role of an HMI is to provide a visual representation of the industrial processes, displaying real-time data, trends, and alarms, and allowing operators to interact with the system by making adjustments or responding to alarms.

PLC: The primary role of a PLC is to control the operation of machinery and processes. It executes the control logic programmed by engineers, reads sensor inputs, performs logic calculations, and sends output signals to control actuators and devices.

Communication:

HMI: HMIs often communicate with PLCs and other devices using industrial communication protocols. They gather data from PLCs and display it in a human-readable format.

PLC: PLCs communicate with sensors, actuators, and other devices in the field to read inputs and send control outputs. They can also communicate with HMIs and higher-level control systems for data exchange and remote control.

In summary, an HMI is the user interface that allows humans to interact with industrial processes, while a PLC is the device responsible for executing the control logic and automating those processes. Together, they form a crucial part of industrial automation systems, enabling efficient and safe operation of various industrial applications.

Difference Between PLC and SCADA

PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) are two distinct components often used in industrial automation and control systems. While they are related and often work together, they serve different functions within an industrial environment. Here's a breakdown of the differences between PLC and SCADA:

PLC (Programmable Logic Controller):

- Function: PLCs are specialized computers designed to control industrial processes and machinery. They execute logic-based tasks, process inputs from sensors, and provide outputs to control various devices such as motors, valves, and relays.

- Programming: PLCs are programmed using ladder logic or other programming languages specifically tailored for industrial control. This programming defines the logic and behavior of the controller.

- Real-time Control: PLCs are optimized for real-time control tasks, making them suitable for applications where precise timing and rapid response are crucial.

- Hardware: PLCs are available in various sizes and configurations to match the complexity of the process they are controlling. They typically have digital and analog input/output modules to interface with sensors and actuators.

- Scalability: PLC systems can be easily scaled by adding more PLCs or expanding the existing hardware to accommodate larger and more complex automation systems.

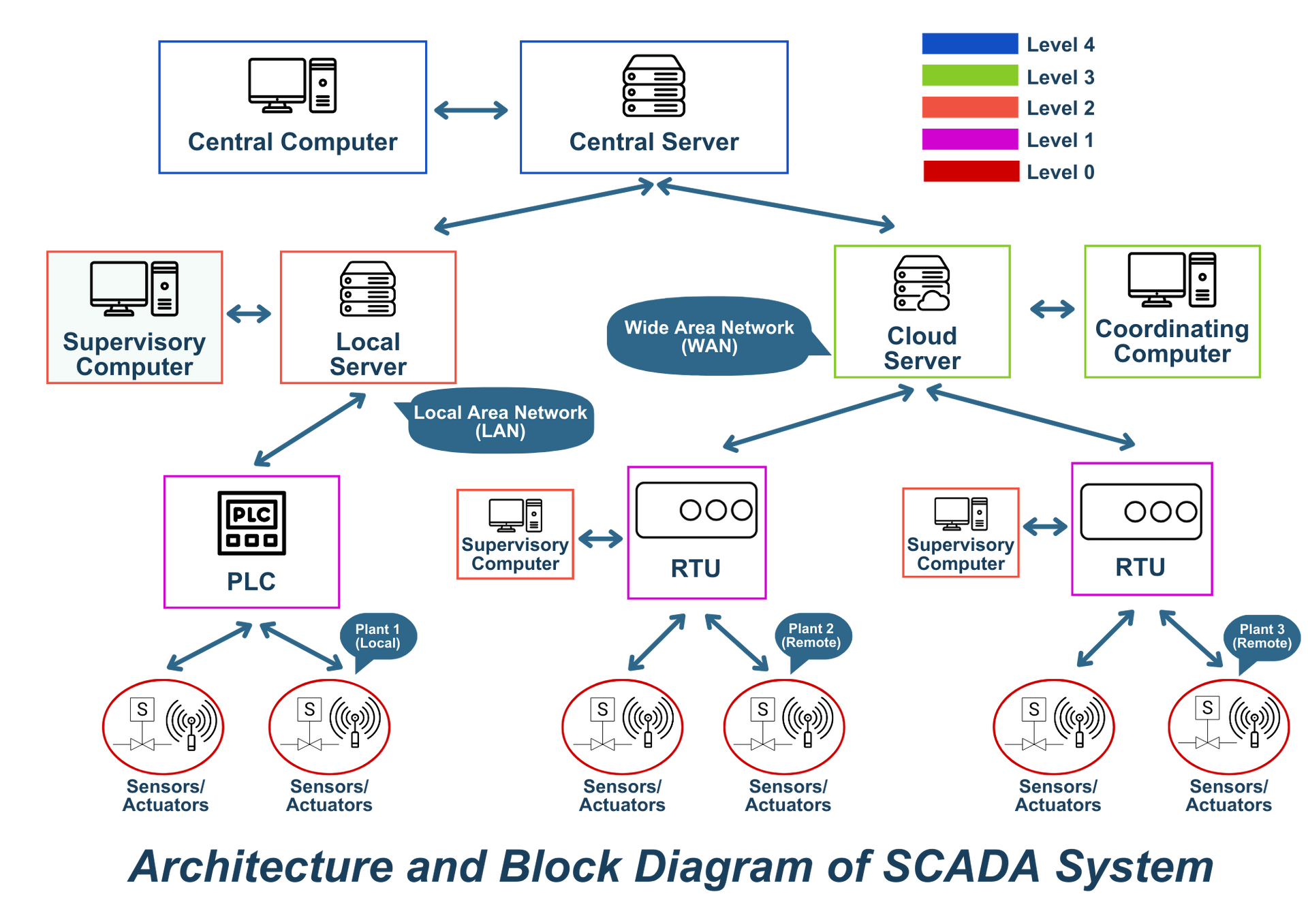

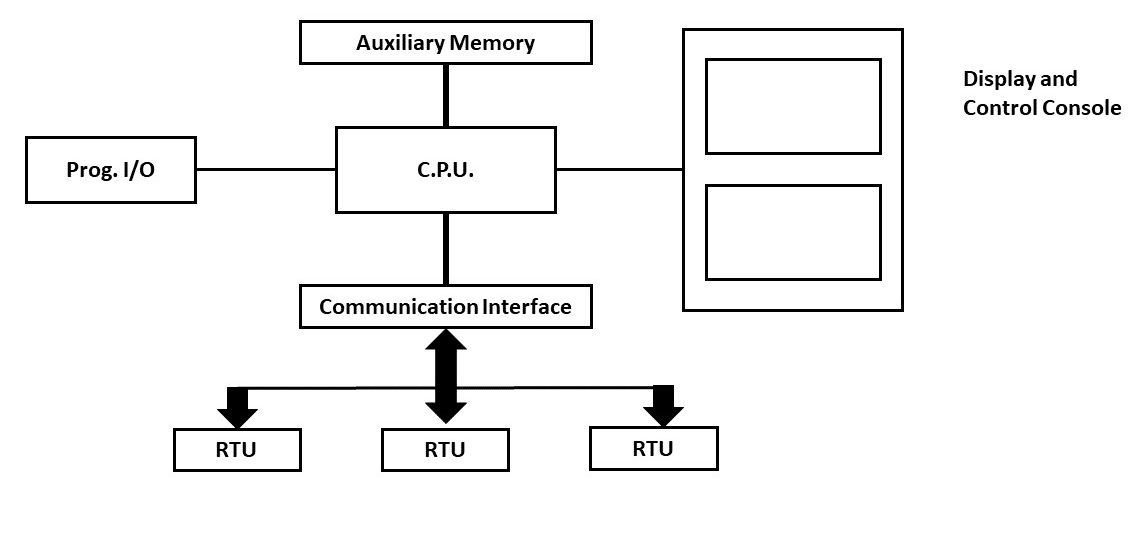

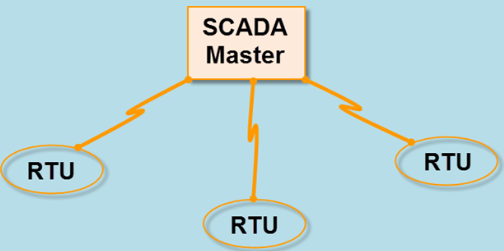

SCADA (Supervisory Control and Data Acquisition):

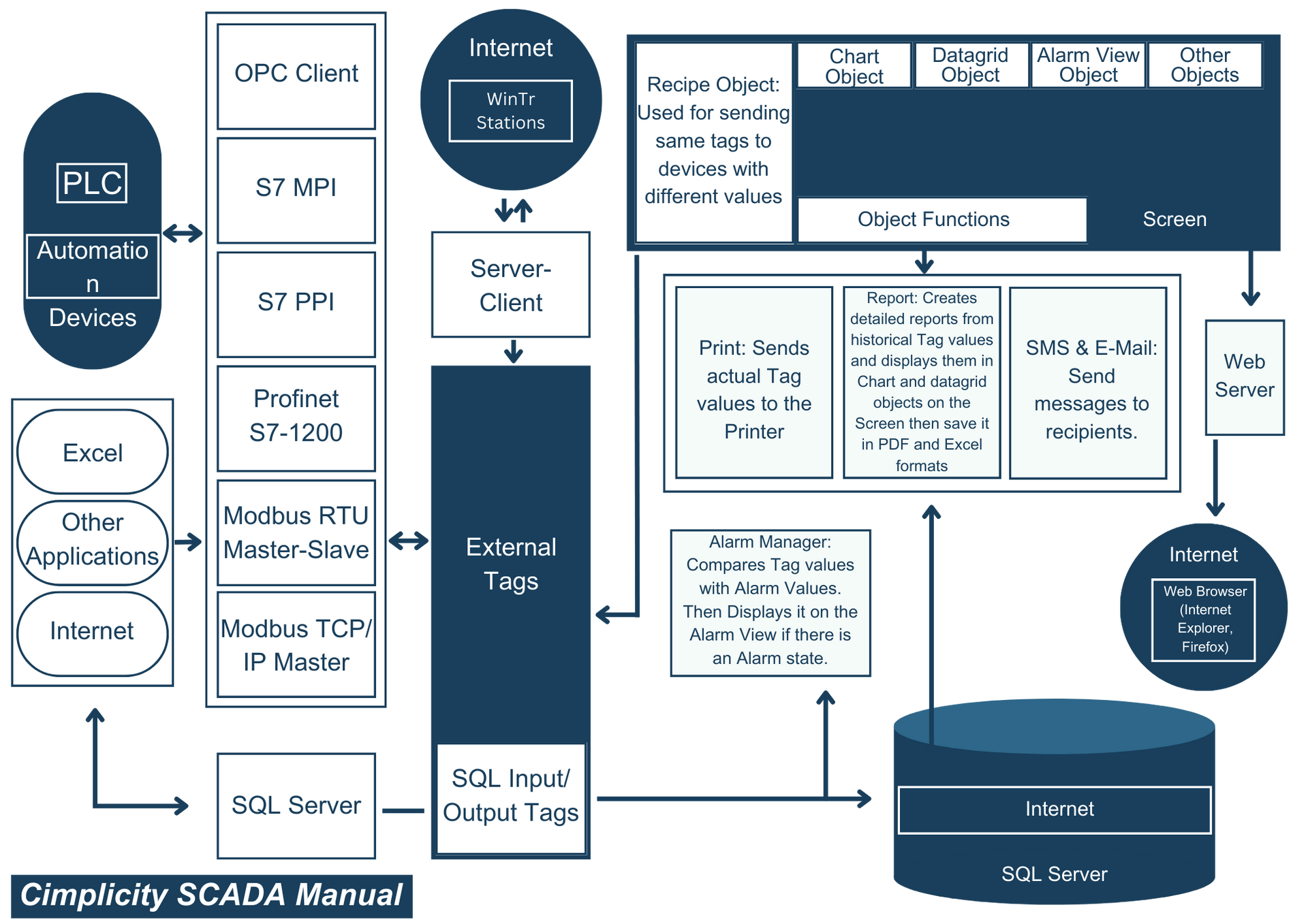

- Function: SCADA systems are software applications that provide a visual interface for monitoring and controlling industrial processes from a central location. They gather real-time data from various devices and sensors and provide operators with a graphical representation of the process.

- Visualization: SCADA systems display real-time data in the form of graphics, charts, and alarms. They allow operators to monitor the status of the entire system and intervene if needed.

- Data Collection: SCADA systems collect and store historical data for analysis and reporting. This data can help identify trends, optimize processes, and improve efficiency.

- Remote Monitoring and Control: SCADA systems enable remote monitoring and control of industrial processes, which is particularly useful for large-scale or geographically dispersed systems.

- Integration: SCADA systems can integrate with various data sources, including PLCs, sensors, databases, and other software systems, to provide a comprehensive overview of the entire process.

- HMI (Human-Machine Interface): The graphical interface provided by SCADA systems is often referred to as the HMI. It allows operators to interact with the system, acknowledge alarms, and initiate control actions.

In summary, PLCs are the hardware-based controllers responsible for executing control logic and interacting with devices in an industrial process. SCADA systems, on the other hand, are software-based tools that provide a visual interface for monitoring, data collection, and remote control of industrial processes. Together, they form a comprehensive solution for automating and managing complex industrial operations.

PLC and SCADA Training Online

Udemy: Udemy is a popular online learning platform that offers a variety of PLC and SCADA courses. You can find courses suitable for beginners as well as more advanced users. Look for courses with good ratings and reviews to ensure their quality.

Coursera: Coursera collaborates with universities and organizations to provide high-quality online courses. You might find courses related to industrial automation, PLC, and SCADA systems from reputable institutions.

LinkedIn Learning (formerly Lynda.com): LinkedIn Learning offers a range of courses on industrial automation topics, including PLC and SCADA systems. These courses often come with high production values and experienced instructors.

Online Industrial Automation Training Providers: There are specialized online platforms that focus on industrial automation training. Examples include:

RealPars: They offer various courses on industrial automation, including PLC and SCADA topics.

Automation Training: This platform specializes in providing online training for PLC, HMI, and SCADA systems.

YouTube: There are many YouTube channels dedicated to providing tutorials on PLC and SCADA systems. Channels like "TheAutomationSchool" and "RealPars" offer educational videos on these topics.

Local Technical Institutes and Universities: Sometimes, local technical institutes or universities offer online courses or webinars on industrial automation, including PLC and SCADA. Check with institutions in your region.

ISA (International Society of Automation): ISA offers a wide range of resources and training opportunities related to industrial automation, including PLC and SCADA systems.

Difference Between HMI and SCADA

Function and Scope:

HMI (Human-Machine Interface): An HMI is a user interface that allows operators and engineers to interact directly with machines, processes, and equipment. It provides a visual representation of real-time data, controls, alarms, and other information in a user-friendly manner. HMIs focus on local control and visualization, allowing operators to monitor and control individual components or processes.

SCADA (Supervisory Control and Data Acquisition): SCADA systems are broader in scope and encompass a larger area of control and monitoring. SCADA systems provide a centralized platform for supervising and managing multiple processes, systems, and equipment distributed across different locations. SCADA systems are designed for remote monitoring, data acquisition, and control of interconnected processes.

Application Level:

HMI: HMIs are typically used at the machine or equipment level. They are closely associated with a single piece of machinery or a specific process and provide the operator with a focused view and control over that particular component.

SCADA: SCADA systems operate at a higher level, often managing multiple HMIs and processes within a facility or even across multiple facilities. They provide a broader view of the entire system and allow operators to monitor and control various processes from a centralized location.

Scale and Complexity:

HMI: HMIs are suitable for smaller-scale operations and processes that require local control and monitoring. They are used in scenarios where a limited number of machines or equipment need to be managed.

SCADA: SCADA systems are designed for larger and more complex operations that involve numerous interconnected processes, extensive data collection, and remote management. They are capable of handling a greater number of devices, data points, and subsystems.

Data Storage and Analysis:

HMI: HMIs often focus on real-time data visualization and control. They may store some historical data for immediate reference, but their primary role is to provide a graphical representation of the current state.

SCADA: SCADA systems typically include more advanced data storage and analysis capabilities. They can store historical data over extended periods and offer tools for trend analysis, performance optimization, and reporting.

Remote Access and Control:

HMI: HMIs are generally intended for local or near-local control. While some HMIs may offer remote access capabilities, they are typically used for on-site interactions.

SCADA: SCADA systems excel at remote access and control. They enable operators to monitor and control processes from a central location, making them suitable for scenarios where remote management and oversight are required.

In summary, while both HMI and SCADA play vital roles in industrial automation, they differ in their scope, focus, and application. HMIs are geared towards local control and visualization of specific processes or equipment, while SCADA systems provide a broader platform for supervising and managing complex, interconnected systems across multiple locations.

Difference Between SCADA and DCS

1. Scope and Scale:

- SCADA (Supervisory Control and Data Acquisition): SCADA systems are designed to monitor and control large-scale processes and distributed systems. They are typically used for managing geographically dispersed facilities, such as utility networks, water treatment plants, and oil and gas pipelines.

- DCS (Distributed Control System): DCS systems are focused on controlling processes within a single plant or facility. They are used to manage various production processes, such as those found in manufacturing, chemical processing, and power generation plants.

2. Control Philosophy:

- SCADA: SCADA systems primarily emphasize supervisory control, real-time monitoring, and data acquisition. They provide operators with an overview of the system's status and allow them to make high-level decisions.

- DCS: DCS systems are more oriented toward process control, focusing on regulating and optimizing individual processes within a facility. They often include advanced control algorithms to maintain precise control over variables like temperature, pressure, and flow.

3. Architecture:

- SCADA: SCADA systems often have a client-server architecture. They gather data from remote field devices and sensors, and this data is then transmitted to a central supervisory system where operators can visualize and control the processes.

- DCS: DCS systems use a distributed architecture where controllers are placed strategically throughout the facility, close to the processes they control. This allows for faster response times and reduces the potential impact of communication failures.

4. Scalability:

- SCADA: SCADA systems are highly scalable and can accommodate a large number of remote sites, making them suitable for managing extensive infrastructure networks.

- DCS: DCS systems are designed for scalability within a single facility. As the needs of the facility grow, more controllers and modules can be added to the existing system.

5. Integration and Connectivity:

- SCADA: SCADA systems often integrate with different types of equipment and systems, including various communication protocols and data sources, making them suitable for diverse applications.

- DCS: DCS systems focus on integration within a specific facility, usually involving the connection of various field devices and instruments within the same industrial process.

6. Alarming and Monitoring:

- SCADA: SCADA systems provide advanced alarming and remote monitoring capabilities to identify and respond to critical events across distributed systems.

- DCS: DCS systems offer real-time monitoring and more precise alarm handling for the processes they control within a single facility.

In summary, while both SCADA and DCS are used in industrial automation and control, SCADA is better suited for supervisory control and monitoring of geographically dispersed systems, whereas DCS is designed to optimize and control individual processes within a single facility. The choice between the two depends on the specific requirements and scope of the application.

PLC HMI Programming

PLC HMI programming involves creating the logic and interface necessary for a Human-Machine Interface (HMI) to interact with a Programmable Logic Controller (PLC). This integration allows operators and engineers to monitor and control industrial processes using a user-friendly graphical interface. Here's a general outline of the steps involved in PLC HMI programming:

1.

Define Project Requirements:

Clearly understand the requirements of the project, including the processes to be controlled, the data to be monitored, and the user interactions needed through the HMI.

2.

Select Software Tools:

Choose the appropriate software tools for both PLC programming and HMI design. Popular choices for PLC programming include Siemens TIA Portal, Allen-Bradley Studio 5000, and Mitsubishi GX Works. For HMI design, software like FactoryTalk View (Rockwell), WinCC (Siemens), or Wonderware InTouch might be used.

3.

PLC Programming:

Develop the logic for the PLC that controls the industrial processes. This involves writing ladder logic, structured text, or other programming languages supported by your PLC. The PLC logic will read inputs from sensors, execute control algorithms, and generate outputs to control actuators and devices.

4.

Configure PLC-HMI Communication:

Set up communication protocols between the PLC and the HMI software. Most HMIs offer communication drivers that allow them to communicate with various PLC brands and models. Configure the data exchange parameters like data addresses, communication type (e.g., Ethernet, serial), and polling rates.

5.

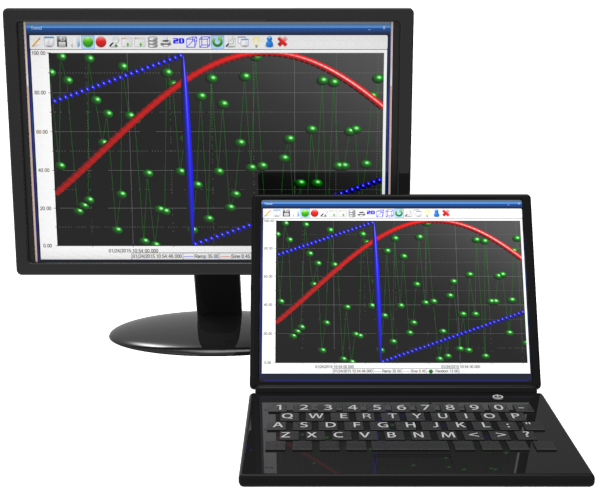

Design HMI Interface:

Create the graphical user interface on the HMI software. This involves designing screens, arranging visual elements (buttons, indicators, graphs), and mapping them to the corresponding PLC data points. Consider the layout, color schemes, and organization for a user-friendly experience.

6.

Link HMI Elements to PLC Logic:

Associate the HMI elements with the PLC logic. Link buttons to control outputs, display sensor data on indicators or graphs, and map alarms to appropriate events. This mapping enables bidirectional communication between the HMI and PLC.

7.

Implement User Interactions:

Define how users interact with the HMI. Add navigation buttons, pop-up screens, and touch gestures as needed. Implement user authentication and access levels if security is a concern.

8. Testing and Debugging:

Test the entire system thoroughly. Verify that the HMI accurately displays real-time data and responds correctly to user inputs. Test different scenarios and edge cases to ensure the system operates as intended. Debug and fix any issues that arise during testing.

9.

Documentation:

Create documentation that outlines the HMI layout, navigation paths, and explanation of controls. Include any setup instructions for communication between the HMI and the PLC.

10.

Training and Deployment:

Provide training to operators and engineers on how to use the HMI effectively. Once the testing and training are complete, deploy the HMI-PLC system in the actual industrial environment.

Remember that PLC HMI programming can vary based on the specific PLC and HMI software you're using, as well as the requirements of your industrial application. Always refer to the documentation and resources provided by the software vendors for detailed guidance on programming and integration.

PLC, SCADA and HMI Courses

PLC, SCADA, and HMI are all related to industrial automation and control systems. Here's a brief overview of each and the types of courses you might consider for each topic:

- PLC (Programmable Logic Controller):

PLCs are specialized digital computers used for automating electromechanical processes in industries. They are programmed to control various processes and machinery. Courses in PLC programming cover topics like ladder logic, programming languages (such as Structured Text, Function Block Diagrams), interfacing with sensors and actuators, troubleshooting, and industrial communication protocols.

Courses:

- Basic PLC Programming: Covers the fundamentals of PLCs, including programming logic and basic troubleshooting.

- Advanced PLC Programming: Goes into more complex programming concepts, motion control, and integration with other systems.

- PLC Troubleshooting and Maintenance: Focuses on identifying and solving common issues in PLC-based systems.

- SCADA (Supervisory Control and Data Acquisition):

SCADA systems are used for remote monitoring and control of industrial processes. They gather data from sensors and other devices, display it to operators, and allow operators to control processes remotely. SCADA courses cover topics like system architecture, data visualization, alarm management, security, and network communication.

Courses:

- Introduction to SCADA: Provides a general overview of SCADA systems and their components.

- SCADA System Design: Covers the planning, design, and implementation of SCADA systems.

- SCADA Security: Focuses on securing SCADA systems from cyber threats and unauthorized access.

- HMI (Human-Machine Interface):

HMIs are user interfaces that allow operators to interact with and control machinery and processes. They can include touchscreen displays, buttons, and indicators. Courses on HMI design and programming teach students how to create user-friendly interfaces that provide efficient control and monitoring of industrial processes.

Courses:

- HMI Design Principles:

Covers user experience design, layout, and visualization techniques for effective HMIs.

- HMI Programming:

Teaches how to program HMIs to interact with PLCs and other control systems.

- Advanced HMI Development:

Explores more complex features like data trending, historical data visualization, and remote access.