Automatic Manufacturing: A Beginner's Guide to Success

Beginner's Guide to Automatic Manufacturing Solutions

Key Highlights

- Automatic manufacturing uses advanced industrial automation to improve how things are made, make the work faster, and help cut down costs.

- The different types of automation, like fixed, programmable, and flexible, help change old assembly lines, move materials, and check on quality in new ways.

- Companies use real-time data, robotic systems, and artificial intelligence to get their work right and help with continuous improvement.

- When you use automation technology, you can get more production speed, better product quality, lower operating costs, and make customer satisfaction higher.

- To make automation work well, you have to do good planning, bring all your systems together, pick the right equipment, and train your team for success that lasts.

Introduction

Automatic manufacturing solutions are changing how industries work with new industrial automation technologies. When businesses use automation in their production processes, they can be more efficient and have fewer mistakes in the production lines. This also makes their work easier and faster. There are different types of automation, like flexible automation, systems you can program, or hard automation setups. These kinds of manufacturing automation help companies in different ways, so they can pick what fits their needs best.

With new changes coming all the time, manufacturing automation helps companies improve how their production processes work. They can keep up with what the market wants and follow the latest industry rules. Let’s look at these important solutions and see how industrial automation is changing modern manufacturing.

Understanding Automtic Manufacturing

Automatic manufacturing brings together smart ideas from people and the accuracy of machines. It uses technology and data systems in the production line to make things run better and need less work from people. Businesses use manufacturing automation to improve how they make things in many different industries.

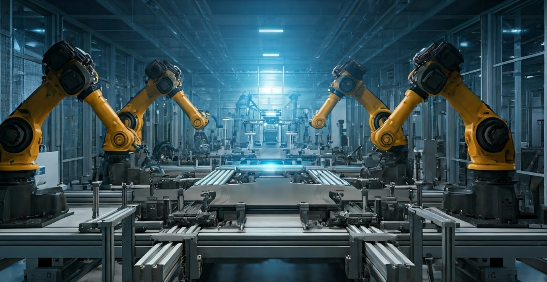

You will find everything from programmable automation, which helps with batch production, to more flexible setups that can change in real-time. Automatic manufacturing shows how important it is to be able to adjust. Robotic arms, control systems, and industrial sensors all work together. They help give the same good results each time, solve slowdowns in how things are made, and cut down on costs. Keep reading to learn more about how it works and what the main parts are.

What is Automatic Manufacturing?

Automatic manufacturing uses technology in production processes to make things faster and better, while also cutting down on manual work. Programmable automation is used in batch production. Here, machines are programmed to make different types of products. For example, programmable logic controllers (PLCs) can control many different manufacturing steps automatically.

Flexible automation takes this even further by letting systems adjust quickly to new production needs. You often see this kind of setup in today’s assembly lines. It is the best choice when industries need updates often and can’t stop work. Advanced robotics also show what flexible automation can do, with remote controls that help make changes fast.

Fixed or hard automation is different. This type is all about making large amounts of the same items in a simple, steady way, such as what you find in chemical manufacturing processes or production lines in the automotive industry. All three types—programmable automation, flexible automation, and hard automation—come together to make modern manufacturing stronger. They help companies meet all kinds of needs, stay ready for changes, and keep quality high.

Key Components of Automatic Manufacturing Systems

Automatic manufacturing systems use advanced control systems, industrial robots, and well-planned setups. These modern control systems help guide every process with high accuracy. This control is important to stop mistakes and reach perfect results in each step.

Industrial robots play a big role in these systems. They handle complicated jobs like putting products together, welding, or exact cutting work. These machines work much faster and with more skill than people can. For example, in Amazon’s fulfillment centers, robotic arms help move and sort items. This helps to make delivery faster and shows how robotic arms can really change things in manufacturing plants.

These manufacturing plants also use both robots and sensors together with machine tools to help everything flow smoothly. Each part works with the other parts to complete different jobs, change production in real time, and protect product quality at all steps. Because of this, everything runs better and wastes less time. Looking deeper into these parts shows us how these systems may change the way manufacturing plants work in the future and help meet even higher standards of product quality.

Preparing for Automation in Manufacturing

Transitioning to automation takes careful planning across every part of systems and processes. Manufacturing plants have to look at their current ways of working. They need to see what problems or slow-downs are there that automation, like robotic arms, can help fix.

It is also important to bring in key equipment, such as robotic arms and machine handling systems. To make things smoother, businesses should bring in automation tools step by step. They must focus on making sure things can change easily and be ready to help workers learn new skills. Doing all this helps set up the best way to use the latest automation technology at work. These tools can be shaped to fit what each business needs most.

Essential Equipment Needed for Automation

The key to good automation is to bring in new tools like robotic arms, machine tools, and material handling systems. You will see that robotic arms are great for work that needs to be exact, such as welding or putting parts together. With this, there can be less human mistake, and the quality of products can be the same every time.

Machine tools with computer controls, called CNC, give great accuracy in jobs like jewelry making. This helps companies like Tiffany & Co. make detailed pieces with great speed and quality.

Material handling systems are a must-have for better moving and sorting. For instance, aerospace companies like Boeing use these automatic guided vehicles so they can move parts that break easily and keep them safe. When you use all of these tools together, work flows better, production speed goes up, and modern ways of making things pull ahead of the rest.

Evaluating Your Current Manufacturing Processes

Before you start using automation, you need to look at your current manufacturing workflows. Find where the production processes do not work well, have repeating steps, or show low results.

When you check your manufacturing processes, you can see what works and what does not. A good example is machine monitoring. This shows you real-time data about equipment effectiveness and any places that slow down production. This helps you decide where automation can be added best.

Also, you need to see if your current setups can grow to handle automated solutions. When you look at your output and inventory management, you can make changes that help the system keep up with new needs in the industry.

Step-by-Step Guide to Implementing Automation

A phased approach can help make the move to automation smooth and allow it to grow as you need. You need to carry out a good assessment first. It is also key to bring systems together with strong training for everyone involved.

Start by looking at the workflows you have now. Find parts of your process that can get better. Pick automation technology that fits your company’s goals. After that, add systems like the Industrial Internet of Things (IIoT) or other parts of the internet of things. This helps your systems run together without issues. Finish with careful testing and make sure each person is properly trained. This will help your team understand and welcome these changes.

Step 1: Assess and Plan

Effective implementation begins when you look at your inventory management and how things are running right now. You need to keep an eye on the inventory levels and how stock is moving. This helps you find the places where things slow down or do not work well. These are the spots that might need automation.

Try to see how automation can fix the problems you find. When you plan, make sure to set goals that your team can reach. Use your people and supplies in a smart way. Be ready to change your inventory during the early phases of the new system.

Think about what your business might need in the future. Use automation that can grow with you. Doing things this way makes your organisation ready to improve inventory management as the market changes.

Step 2: Select the Right Automation Tools

Choosing the right automation technology begins with knowing how the application of automation fits your business. Look at different types of automation, like fixed systems that do the same task again and again, or more flexible tools that adjust when making something new or different.

Seeing real examples of automation helps. Robotic arms are used for assembly work and are a great example of tools that add value and make production faster and better. Pick the tools that fit your production and think about what your industry needs most.

When you put money into automation that serves a clear purpose, you help match the technology to what needs to get done. This way, you can improve the process over what you have now. It is important to do this if you want a good path for growth and if you plan to scale your work in the long run.

Step 3: Integrate Systems

Seamless integration in manufacturing automation relies on connecting systems like IIoT for comprehensive visibility. IIoT bridges real-time data with Internet of Things capabilities, propelling unified operations.

Here's an overview of integration benefits: | Integration Element | Description | |-----------------------------|--------------------------------------------------------------------------------| | IIoT Implementation | Centralises data collection for real-time performance monitoring. | |Types of Automation| Ensures compatibility with flexible and fixed systems alongside IIoT controls. | | Automation Platforms | Facilitates interaction between different systems, guaranteeing smooth workflows. |

Fostering deep integration improves manufacturing efficiency while enriching data-driven production strategies.

Step 4: Testing and Quality Assurance

Testing automation solutions helps to keep product quality high. It also finds any design problems. You need to do many checks on these systems. This helps to make each product better for customers and leads to fewer defects.

Quality assurance is all about checking how well things work. Teams use new monitoring tools to see if systems are working the right way. Every automation tool gets tested before it is used. The goal is to make sure they fit with what the company needs.

Customer satisfaction gets better when products are steady and there are fewer recalls. By focusing on keeping quality in check, companies protect their name. This also gives them a way to trust their products for a long time.

Step 5: Training and Change Management

Empowering your human workforce to use automation tools can help close any skill gaps. Before you start with a large project, you should have a full training needs check.

You need programs that help people and robots work together in a better way. This makes moving to new tech much smoother. Training helps people in the workforce stay flexible and calm any first worries they have about changes at work.

Change management steps help the new systems fit in well, so they do not interrupt the way things already work. When your human workforce builds these new skills, this technology push becomes a real team effort. Then, everyone works together in the best way.

Benefits of Adopting Automatic Manufacturing Solutions

Businesses that use manufacturing automation see many benefits. They have faster production speed, smoother processes, and lower operating costs. This shows that it gives real value in the long run.

Automation helps to keep product quality high by making sure each item is the same. It also helps with continuous improvement and supports steady growth. With better customer satisfaction and ways to get better all the time, manufacturing can stay strong over the years and stay ahead in the industry. Manufacturing automation is changing how things are made, making the field ready for what comes next.

Increased Production Efficiency

Automation helps boost how products are made by making work quicker and smoother. Machines can keep going at the same speed, so manufacturers have lower running costs.

Robotic technology gives companies ways to do more work, and people do not get tired. It lets factories work all day and night. These upgrades mean there is less stoppage and more work gets done through the assembly lines.

Quick assembly lines that use automation tools can keep up with big jumps in demand. This is very important for industries that care about lean manufacturing. When these systems work well, they help companies reach their goals and do well for a long time.

Enhanced Product Quality and Consistency

Automation helps raise product quality because it lets people make things without mistakes. It keeps batch production the same every time by stopping human errors.

Flexible automation fits well in continuous improvement cycles. It can change fast when there are new rules to follow. The better quality that comes from this helps build trust with customers and keeps them happy.

Getting product standards right shows how technology is changing the way we make things today. Every detail matters, and automation gives the kind of accuracy that people want and deserve.

Common Challenges and Solutions in Automation

Moving to automation can bring some challenges, but acting early helps handle them well. At first, you may have to pay some extra costs, but with data analytics and cutting unnecessary spending, you can make up for it.

Plus, if you find skill gaps in your team, training programs will help everyone work better. Over time, automation is worth it because it helps you beat early problems and keep things running well for the long run.

Overcoming Initial Investment Costs

Investing in automation systems comes with some upfront costs. But over time, the use of advanced data analytics can help find ways to cut costs. This helps the business stay stable with money after the new system is put in place.

Manufacturing plants can bring their resources together better. They do not have to use many different operating systems. Tools like predictive maintenance help lower the money spent on fixing breakdowns over the years.

When you use the advantages of automation the right way, your business can make the new system pay off after the early stages. It is important to find the right balance. Data analytics is also a tool you really need.

Addressing Skill Gaps and Training Needs

Skill gaps in workers show up when the move to automation begins. These training programs give real examples of how to go from doing work by hand to working with machines. This helps make sure the change is steady.

These steps help people as they learn new things, so the whole human workforce feels less stress. Certain tools help people get used to new ways of working, even in industries that still need a lot of human workforce.

By using technology made for people at work, companies meet training needs with less trouble. This helps people who run machines and automated systems work better together.

Conclusion

In the end, using automatic manufacturing solutions gives businesses a great chance to get better at what they do. When you know the key parts and get ready the right way, you can get past common problems. You will also see big gains, such as more efficient work and better product quality. The road to automation does have some bumps, but with good planning and the right tools, you can really move forward. If you want to see how automation can help make your manufacturing better, get in touch with us for a free consultation. Your way to efficient manufacturing begins now!

Frequently Asked Questions

How Long Does It Take to Implement Manufacturing Automation?

The time it takes to put new automation in place can change based on the types of automation you choose and how hard the process is. Some systems can have impacts right away. But, if you want to add process automation to the whole manufacturing process, it may take months to get, set up, and fit it into an effective manufacturing process.

What Are the Long-Term Benefits of Automation?

Long-term benefits are lower operating costs, better continuous improvement, higher production efficiency, and more customer satisfaction. Automation helps make product quality steady and strong. It also lets businesses get better at changing with the market. This helps them stay ahead of others.

Can Small Businesses Benefit from Automation?

Yes! Automation solutions can help save money in production processes, even as you grow. When you use flexible technology that fits what you need, the business can do better. It helps you work faster and get more done without spending too much. This way, you can improve how things run and make your work possible for less money.

How Does Automation Impact Workforce Dynamics?

Automation changes the way people work by helping humans and robots work together. Workers see their jobs change, and they need to learn new skills. People also have to get used to using new technology. Training is now an important part of the process. It helps the human workforce and automated systems work well together.