Discover Innovations at Automatic Manufacturing Limited

Discover Innovations at Automatic Manufacturing Limited

Key Highlights

- Decades of manufacturing experience: Over 30 years of expertise in providing innovative solutions for diverse industries.

- Injection molding expertise: 443 machines with press sizes ranging from 6 to 1,600 tons ensure precision and scalability.

- Comprehensive manufacturing services: Vertically integrated operations cater to medical device production and other industries.

- Contract manufacturing excellence: Tailored solutions paired with streamlined processes enhance cost efficiency and product quality.

- Commitment to high quality: ISO-certified facilities deliver world-class compliance and precision.

- Advances in automation: Robotics and IoT integration optimise production processes and drive unmatched efficiency.

Now, let's explore these innovations and how they’re shaping the future of manufacturing.

Introduction

Automatic Manufacturing is known for the best in manufacturing services and solutions. The company has more than thirty years of manufacturing experience. It makes high-quality products for the medical, industrial, and home automation fields. The prices are low and fit different needs. The team uses advanced injection molding and top automation skills. This helps them to scale the production up or down as needed. The company always looks for new ways to improve what it does. They use smart technology to make their work more correct and smooth. See how their work in automation and manufacturing services is helping to raise the bar for the industry all over the world.

Pioneering Technologies Shaping Automatic Manufacturing

Automatic Manufacturing Enterprise changes the way people look at manufacturing by using new technology. The company brings in advanced automation systems and makes use of IoT-enabled solutions. Their work sets the standard for both how exact and how fast things get done. These new ways make sure you get top-quality products and help simplify tough jobs for many industries.

In addition, Automatic Manufacturing Enterprise is known for great manufacturing services. They help with product design and development, making things move smoothly and quickly. With strong certifications and their presence in many places around the world, they offer custom solutions and great flexibility. Because of this, companies get to enjoy contract manufacturing that grows with their needs. Up next, learn how advanced robotics and the use of data analytics make contract manufacturing even better.

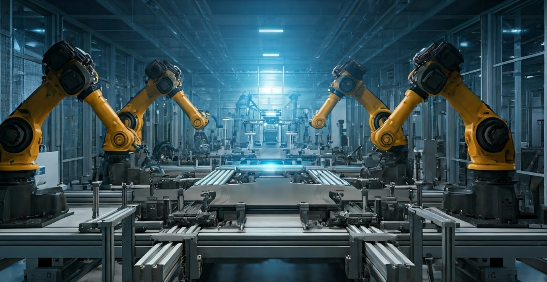

Advanced Robotics and Automation Solutions

As companies look for ways to work better, robotics has become a big part of automation today. Automatic Manufacturing uses the latest robotics in its work to help make and speed up production lines. In product assembly and injection molding, these automated systems help give the best in speed, accuracy, and quality.

These smart systems help contract manufacturing by making mistakes less likely, improving safety, and allowing work on many different sizes of production runs. Because of these advantages, Automatic Manufacturing is a good choice for big industries such as healthcare and automotive. With robots taking on the hard parts of making things, businesses can make their work easier and faster without lowering quality or missing deadlines.

You get perfect work, help in saving money, and faster times to launch products. Automatic Manufacturing brings reliability and better ways to get jobs done, helping industries get ahead. By using smart manufacturing, IoT, and looking at data, companies can change how they work for the better.

Smart Manufacturing with IoT and Data Analytics

Smart manufacturing is changing the way people make things today, and Automatic Manufacturing is at the front of this change. They use IoT and data analytics to let machines and people share data all the time. This gives real-time monitoring and helps boost efficiency on the factory floor. Their skills in automation and injection molding have gotten even better because they use data to help make decisions and use predictive maintenance for their machines.

A text table highlighting key benefits of IoT and analytics:

| IoT and Analytics Feature | Impact on Manufacturing |

|---|---|

| Real-time monitoring | Immediate insights into production efficiency and machinery performance |

| Predictive maintenance | Reduces downtime and extends equipment lifespan |

| Enhanced data analytics | Optimizes injection molding precision and output consistency |

| Streamlined workflow | Effortless scaling and seamless manufacturing services |

Because of the use of these new technologies, Automatic Manufacturing can follow exact standards and handle more work smoothly. They also connect new ideas with the actual making of products. This helps them work on sensitive jobs, such as medical device production, with better quality than others. Their automation, injection molding, and manufacturing services help them do this for their customers, every time.

Conclusion

To sum up, when you look at what’s new at Automatic Manufacturing, you see many changes in the way people use automation. The use of robots, IoT, and data tools is changing how people do work in the industry. These tools don’t just help people do things faster. They also help save resources and get more work done. With automation added to the way people make things, businesses can keep up with others and answer the needs of the market quickly. As we go into the future, it will be very important for all of us to use these new ways if we want to do well in this changing world of making things. If you want your business to grow with new tools, reach out to us today for a free talk!

Frequently Asked Questions

What sets Automatic Manufacturing apart in the industry?

Automatic Manufacturing has many years of manufacturing experience. They stand out for their new ways of doing injection molding and strong manufacturing services. The team offers contract manufacturing that is made to fit what you need. They are known for high quality. Their work is done in factories around the world, and they have ISO certificates to show they keep up with the rules and keep things the same for everyone.

How does automation improve manufacturing efficiency?

Automation helps speed up work by making things simpler, lowering mistakes from people, and making the way we do tasks better. When companies use advanced robotics, they can bring down costs, do things with good precision, and change how they work more easily. This makes it simple to grow as needed. With many years of offering good service, Automatic Manufacturing shows what new and efficient contract manufacturing with automation can do.

Are there sustainable practices integrated into Automatic Manufacturing?

Yes, sustainability is a big part of Automatic Manufacturing. They use automation that is very precise to cut down waste and use less energy. Their injection molding is also done in a way that helps the environment. The company has ISO 14001 certification, so you know they care about the planet and still provide top manufacturing services.

What industries benefit most from Automatic Manufacturing innovations?

Industries such as medical devices, automotive systems, home automation, and industrial controls all do well with Automatic Manufacturing’s new ideas. The company’s skill in injection molding and their top contract manufacturing services help give high-quality results. When you need projects with great precision and good reliability, their manufacturing services and automation solutions are a strong choice.

How can businesses adopt these manufacturing solutions?

Businesses can get many benefits from Automatic Manufacturing's solutions. They use automation and injection molding skills in their work. With them, you get contract manufacturing done without any hassle. You can count on tailored and scalable projects. These are built with fast and good manufacturing services.