Beginner's Guide to Automation PLC: What You Need to Know

Key Highlights

Here is a summary of what you will learn in this guide:

- A programmable logic controller (PLC) is a rugged industrial computer designed for automating manufacturing processes.

- PLCs are the modern replacement for older, hard-wired relay logic systems, offering greater flexibility and reliability.

- The core function of a PLC involves reading inputs, executing a program, and controlling outputs for process control.

- Understanding PLC programming, often done with languages like Ladder Logic, is essential for customizing automation tasks.

- PLCs consist of key components, including a CPU, I/O modules, and a power supply, all built for industrial environments.

- These devices are fundamental to

industrial automation across many sectors, from food processing to robotics.

Introduction

If you are exploring the world of industrial automation, you have likely encountered the term Programmable Logic Controller (PLC). A PLC is the workhorse behind modern manufacturing and process control, acting as the brain of automated operations. This guide offers a comprehensive look into the PLC system, explaining what it is, how it functions, and why it has become an indispensable tool. Whether you are a student, technician, or engineer, understanding the principles of the programmable logic controller is your first step toward mastering automation.

Understanding PLCs in Automation

At its core, a PLC is a specialized computer built to manage and automate electromechanical processes. These programmable controllers are the foundation of modern control systems, interpreting information from sensors and making decisions to operate machinery. They are designed to handle a wide range of tasks with precision and reliability.

Their application of programmable logic allows for immense flexibility, a significant upgrade from the rigid, hard-wired systems of the past. To fully grasp their impact, it is important to first understand what a PLC is and the specific ways it is deployed in today's advanced automation systems.

What is a Programmable Logic Controller (PLC)?

A Programmable Logic Controller (PLC) is an industrial digital computer designed to automate manufacturing processes, machinery, or entire production lines. Unlike a standard desktop PC, a PLC is built to withstand harsh industrial conditions, including extreme temperatures, vibrations, and electrical noise. Its primary role is to execute a series of control instructions stored in its programmable memory.

The operation begins when the PLC receives signals from various input devices, such as switches, sensors, or buttons. These signals provide real-time data about the state of the machinery or process. The PLC's central processing unit (CPU) then processes this information according to the user-written program.

Based on the logic in the program, the PLC sends commands to output devices like motors, valves, lights, or alarms, thereby controlling the industrial process. This continuous cycle of reading inputs, processing logic, and updating outputs happens in milliseconds, enabling precise and responsive automation.

How PLCs Are Used in Modern Automation Systems

In modern industrial automation, PLCs serve as the central controllers for a vast array of applications, ensuring that complex operations run smoothly and efficiently. They are the key to achieving precise control of machinery, managing everything from simple, repetitive tasks to sophisticated, multi-stage processes. Their ability to operate in real time makes them essential for high-speed manufacturing environments where timing is critical.

PLCs are also fundamental to process control, where they monitor variables like temperature, pressure, and flow to maintain optimal conditions. They can communicate with other systems, such as SCADA (Supervisory Control and Data Acquisition) and HMI (Human-Machine Interface), to provide operators with a comprehensive view of the plant floor and allow for direct intervention.

Common applications where PLCs are indispensable include:

- Conveyor Systems: Managing the speed and flow of products on an assembly line.

- Robotic Cells: Coordinating the movements and actions of industrial robots.

- Temperature Control: Regulating heaters and coolers in food processing or chemical production.

Key Components of a PLC System

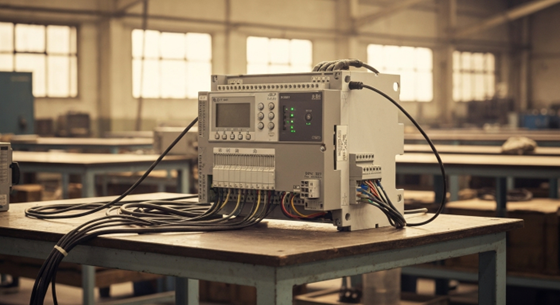

A PLC system is more than just a single box; it is a collection of interconnected components that work together to achieve automation. These industrial computers are modular by design, allowing you to build a system that perfectly fits your application's needs. The primary components are the central processing unit (CPU), the input and output (I/O) modules, and the power supply.

Each part plays a crucial role, from the processing unit that executes your program to the input devices that sense the environment and the output devices that perform actions. Let's examine these core components more closely.

Central Processing Unit (CPU)

The Central Processing Unit (CPU) is often described as the brain of the PLC. This microprocessor-based processing unit is responsible for carrying out all the logic, calculations, and commands that make up your automation program. It continuously runs a scan cycle where it checks the status of inputs, executes the stored user program, and then updates the outputs accordingly.

These programmable controllers are specifically designed for the demands of industrial environments. The CPU performs internal diagnostic checks during each cycle to ensure everything is operating correctly, contributing to the system's high reliability. It has different operational modes, such as "Run" mode for executing logic and "Program" mode for downloading new instructions from a programming device.

The CPU's power and speed determine how quickly the PLC can process information and react to changes, making it a critical factor in the performance of complex or high-speed automation tasks.

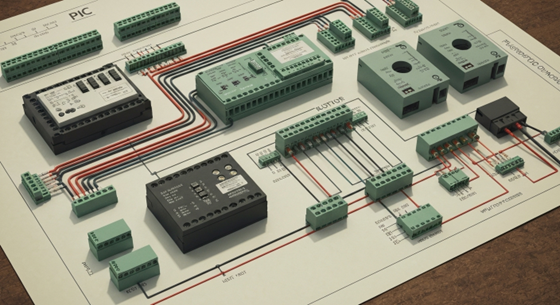

Input and Output (I/O) Modules

Input and Output (I/O) modules are the bridge between the PLC's CPU and the industrial equipment it controls. They convert the electrical signals from sensors and switches into data the CPU can understand and turn the CPU's commands back into electrical signals to operate machinery. Input devices can include anything from simple pushbuttons and proximity sensors to more complex devices that measure temperature or pressure.

I/O modules come in two main types: digital and analog. Digital I/O is for on/off signals, like a switch being open or closed. Analog signals, on the other hand, represent a range of values, like a temperature reading between 0 and 100 degrees Celsius. The PLC uses different modules to handle these distinct signal types.

Similarly, output signals control various output devices. A digital output might turn a motor on or off, while an analog output could adjust a valve's position or a motor's speed. The selection of I/O modules is critical for connecting the PLC to the specific devices in your automated system.

Power Supply and Communication Interfaces

The power supply is a fundamental component that provides the PLC with the stable, low-voltage DC power it needs to operate. It typically converts the standard AC line voltage into the DC voltage required by the CPU and I/O modules. This unit is designed to be robust, ensuring clean power delivery even in the electrically noisy and harsh industrial environments where PLCs are deployed.

Beyond power, communication interfaces are what connect the PLC to the wider world. These interfaces allow the PLC to exchange data with other devices, such as HMIs, other PLCs, or enterprise-level computer systems. They support various communication protocols, enabling seamless integration into a larger network. This connectivity is crucial for monitoring processes from remote locations or collecting data for analysis.

PLCs can use several communication protocols, including:

- EtherNet/IP: A widely used protocol for industrial automation that leverages standard Ethernet technology.

- Modbus: A classic serial communication protocol that remains popular for its simplicity and reliability.

- PROFINET: Another Ethernet-based solution for transmitting data between controllers and devices.

PLCs vs. Traditional Relay Logic

Before the invention of PLCs in the late 1960s, industrial control systems were built using relay logic. These systems relied on electromechanical relays, timers, and counters that were physically wired together to perform logical operations. While effective for their time, they were complex, bulky, and inflexible.

The main difference between these two approaches is how the logic is implemented. In a relay system, any change required a human operator to physically rewire the control panel. With a PLC, the logic is software-based, allowing for quick and easy modifications. Let's explore the key distinctions in their design and the advantages of making the switch to PLCs.

Differences in Operation and Design

The operational design of relay logic systems is fundamentally different from that of a programmable logic controller. Relay logic depends on a physical connection of numerous individual relays to create a control circuit. The logic is literally in the wiring; to change the machine's behavior, you had to change the wires. This made troubleshooting a tedious process of tracing wires through a complex panel.

In contrast, a PLC replaces this maze of wires with a software program. The logic is stored in the PLC's memory, not in the physical wiring. This shift dramatically simplifies the control panel and makes the system far more adaptable. A single PLC can replace hundreds of relays, saving significant space and reducing hardware costs.

This software-based approach also enables PLCs to handle complex operations that would be impractical or impossible to implement with relays. The following table highlights the key distinctions:

| Feature | Relay Logic | Programmable Logic Controller (PLC) |

|---|---|---|

| Logic Implementation | Hard-wired physical connection of relays | Software-based program stored in memory |

| Flexibility | Low; requires manual rewiring for changes | High; easily reprogrammed via software |

| Complexity | Best for simple, fixed tasks | Can manage highly complex operations |

| Maintenance | Difficult and time-consuming troubleshooting | Faster diagnostics through software tools |

| Size | Bulky and requires large control panels | Compact and space-saving |

Benefits of Transitioning to PLC-Based Control

Making the move from traditional relays to PLC-based control systems offers a multitude of benefits that directly impact productivity and reliability. The most immediate advantage is a significant improvement in flexibility. Instead of rewiring panels, you can modify control logic with a few keystrokes, drastically reducing the time and cost associated with process changes or system updates.

Furthermore, PLCs are engineered for dependability. Their robust design, featuring no moving parts, allows them to operate consistently for long periods in demanding industrial settings. This reliability minimizes downtime and boosts overall machine performance. The easy integration of PLCs with other automation technologies, like HMIs and SCADA systems, also provides a clearer view of your operations.

Key advantages of adopting PLC control include:

- Enhanced Safety: PLCs can be programmed with sophisticated safety logic, and specialized safety PLC models are available for critical applications.

- Improved Troubleshooting: Software-based diagnostics help pinpoint faults quickly, reducing repair times.

- Scalability: You can easily expand a PLC system by adding more I/O modules to accommodate new machinery or processes.

Types of PLCs and Common Applications

The world of programmable controllers is not one-size-fits-all. A diverse family of controllers exists to meet the varying needs of different automation tasks, from small, standalone machines to large, interconnected factory floors. These industrial computers can be broadly categorized based on their form factor, I/O capacity, and processing power.

Choosing the right type of PLC is a critical decision that depends on the specific requirements of your project. Understanding the main categories—fixed and modular—is the first step. Afterward, we can explore the wide range of industries where these powerful devices are put to work every day.

Fixed vs. Modular PLCs

PLCs generally fall into two main categories: fixed and modular. A fixed PLC, sometimes called an integrated or compact PLC, has the processor, power supply, and a specific number of input and output points all in one self-contained unit. These are typically smaller, more affordable, and ideal for simple, standalone automation tasks where the I/O requirements are well-defined and unlikely to change.

On the other hand, a modular PLC is designed for scalability and customization. It consists of a base rack or chassis into which you can plug various modules, including different CPUs, power supplies, I/O modules, and communication modules. This "à la carte" approach allows you to build a controller that precisely matches your needs.

If your application is large, complex, or expected to grow, a modular PLC is the superior choice. It allows you to expand the system's capabilities by simply adding more modules. This flexibility in applying programmable logic makes them suitable for a wide range of sophisticated automation challenges, while fixed PLCs excel in smaller, dedicated roles.

Industries That Rely on PLC Automation

The use of PLCs is widespread across nearly every industrial sector due to their versatility and reliability. Their ability to manage everything from high-speed control of machinery to precise process control makes them an essential tool for modern manufacturing and production. Many of these industrial applications integrate PLCs with SCADA systems to provide centralized monitoring and control.

In the automotive industry, for example, PLCs orchestrate robotic welding and assembly lines. In food processing, they control mixing, baking, and packaging operations, ensuring product consistency and safety. The energy sector uses them to manage power generation and distribution, while water treatment plants rely on them to control pumps and valves.

Some of the key industries that depend heavily on PLC automation are:

- Manufacturing: For product assembly, material handling, and quality control.

- Food and Beverage: Automating batching, cooking, and packaging processes.

- Pharmaceuticals: Ensuring precision and compliance in drug manufacturing and packaging.

- Oil and Gas: Controlling processes in refineries and on offshore platforms.

Beginner’s Guide to Getting Started with PLC Automation

Embarking on your first PLC project can seem daunting, but breaking it down into manageable steps makes it accessible for everyone. This beginner’s guide is designed to walk you through the essentials of setting up your first automated system. The journey involves selecting the right hardware, installing the programming software, and learning the basics of PLC programming.

With the right approach, you will be able to translate your ideas into a functional automated process. The following sections provide a step-by-step path to help you get started with confidence.

Essential Equipment and Resources Needed

Before you can start programming, you need to gather the essential equipment and resources for your project. The centerpiece of your setup will, of course, be the PLC itself. However, you will also need a personal computer (PC) to run the PLC programming software, which is the tool you will use to write and download your control logic to the controller.

Next, you must consider the real-world devices your PLC will interact with. You will need sources of input data, such as sensors, switches, or buttons, to provide the PLC with information about its environment. You will also need output devices, like lights, motors, or solenoids, for the PLC to control.

Here is a basic list of the essential equipment you will need:

- A Programmable Logic Controller (PLC): This can be a small, fixed I/O model for beginners.

- A Personal Computer: To install and run the vendor-specific programming software.

- Input and Output Devices: Such as a simple switch for input and an indicator light for output.

- A Power Supply and necessary wiring.

Step-by-Step Guide to Setting Up Your First PLC Project

This step-by-step guide provides a clear roadmap for your first PLC project. The process begins with selecting the appropriate PLC for your task and moves through hardware setup, software configuration, and finally, programming and testing. By following these stages, you can systematically build your automated system from the ground up.

First, you will physically set up your hardware, which involves mounting the processing unit and completing the necessary wiring between the PLC, power supply, and your I/O devices. This creates the physical framework for your control system.

Once the hardware is in place, the focus shifts to the software. You will install the programming software on your computer, configure it to communicate with your PLC, and then write your first program using one of the standard programming languages. The following sections will break down each of these steps in greater detail.

Step 1: Selecting the Right PLC for Your Needs

Choosing the right PLC is the most critical first step in any automation project. With a vast family of controllers on the market, you need to assess your project's specific requirements to make an informed decision. The primary consideration is the number and type of inputs and outputs your system will need. Make a list of all sensors, switches, motors, and valves you plan to connect.

Next, consider the complexity of your control task. For a simple on/off process, a basic PLC will suffice. For tasks involving calculations, data logging, or complex sequencing, you will need a controller with more memory and processing power. You should also evaluate the environmental conditions. If the PLC will operate in an area with extreme temperatures or high vibration, you need to select a model rated for those conditions.

Key factors to consider when selecting a PLC include:

- I/O Count: The number of input data points and output devices you need to control.

- Memory and Processing Power: Required for handling complex logic and fast cycle times.

- Communication Needs: Does the PLC need to communicate with other devices or networks?

- Environmental Ratings: Can it withstand the temperature, humidity, and vibration of its location?

Step 2: Setting Up Hardware and Wiring

Once you have selected your PLC, the next step is the physical installation and wiring. Begin by securely mounting the PLC and its power supply in a control panel or another suitable enclosure. Proper mounting ensures it is protected from physical damage and environmental factors.

The next task is the wiring, which creates the physical connection between the PLC and the rest of your control systems. This involves connecting your input devices (like sensors and switches) to the PLC's input terminals and your output devices (like lights, solenoids, or electric motors) to its output terminals. It is crucial to follow the manufacturer's wiring diagrams carefully to ensure correct and safe connections.

Always double-check your wiring before applying power. Incorrect connections can damage the PLC or the connected devices. Pay close attention to the voltage and current ratings for the I/O terminals to prevent overloading them. A neat and organized wiring layout will also make future troubleshooting much easier.

Step 3: Installing and Configuring PLC Software

With the hardware wired up, it is time to move to the software side of the setup. The first step is to install the PLC programming software on your computer. Each PLC manufacturer, such as Allen-Bradley (a Rockwell Automation brand) or Siemens, has its own proprietary software package, like Studio 5000 or TIA Portal. Make sure you have the correct software for your PLC model.

After installation, you need to perform the initial configuration. This involves creating a new project in the software and specifying the exact hardware you are using, including the PLC model and any I/O modules. This step tells the software what it is working with, which is essential for proper operation.

The final part of configuration is establishing communication between your computer and the PLC. This is typically done via a USB, Ethernet, or serial cable. You will need to configure the communication protocols in the software to match the PLC's settings so that you can download your program and monitor its execution.

Step 4: Writing and Testing Your First PLC Program

Now you are ready for the core activity: PLC programming. This is where you create the logic that will control your automated process. The most common programming language for beginners is Ladder Logic (LD), which uses a graphical format that resembles an electrical relay schematic, making it intuitive for those with an electrical background.

Your first program will likely be simple, such as "when a button is pressed (input), turn on a light (output)." You will create this logic in the programming software using elements like contacts (inputs) and coils (outputs). Other standard languages you might explore later include Function Block Diagrams (FBD) and Sequential Function Charts (SFC).

After writing your program, it is crucial to test it thoroughly. Most software includes a simulation mode that lets you test your logic without being connected to the actual PLC. Once you are confident, you can download the program to the PLC and test it with the real hardware, ensuring it performs as expected before deploying it in a live environment.

Step 5: Troubleshooting and Optimization Tips

Even with careful planning, you may encounter issues. Troubleshooting is a normal part of the development process. Most PLC software includes powerful monitoring tools that allow you to watch your program execute in real time. You can see the status of inputs, outputs, and internal logic, which is invaluable for pinpointing where a problem lies.

Once your system is running, you can focus on optimization. This might involve refining your code to execute more efficiently or adjusting timers and counters to improve machine performance. Data acquisition plays a key role here; by monitoring cycle times and other metrics, you can identify bottlenecks and opportunities for improvement.

Here are a few tips for effective troubleshooting and optimization:

- Check Your Wiring: Many "programming" problems are actually physical wiring issues.

- Comment Your Code: Add notes to your ladder logic to explain what each section does. This will be a huge help when you return to it later.

- Isolate the Problem: Test small sections of your code individually to confirm they work before combining them into a larger program.

PLC Programming Basics

PLC programming is the skill of writing instructions that tell the controller how to operate. This is done using one of several standardized programming languages. While there are a few options, most beginners start with Ladder Logic because of its visual and intuitive nature.

Understanding the fundamentals of these languages is key to unlocking the full potential of your PLC. The most common languages defined by the IEC 61131-3 standard include Ladder Logic (LD), Function Block Diagrams (FBD), and Sequential Function Charts (SFC). Let's look at these in more detail.

Common PLC Programming Languages (Ladder Logic, Function Block, etc.)

While there are five standard PLC programming languages, a few are more common, especially for beginners. The most widely used is Ladder Logic (LD). It is a graphical language that represents program logic with symbols arranged in a format that looks like rungs on a ladder. This design was based on the relay logic circuit diagrams that it replaced, making it easier for electricians and technicians to adopt.

Another popular graphical language is Function Block Diagrams (FBD). This language visualizes logic as a set of blocks connected by lines. Each block performs a specific function (like a timer, counter, or logical AND/OR), and the lines show the flow of data between them. FBD is often preferred for process control applications.

For controlling processes that happen in a specific order, Sequential Function Charts (SFC) are used. This language breaks down a complex process into a series of steps and transitions, making it very easy to visualize and manage sequential operations.

- Ladder Logic (LD): Best for discrete control and easy for beginners.

- Function Block Diagrams (FBD): Ideal for processes involving continuous data flow.

- Sequential Function Charts (SFC): Excellent for managing step-by-step processes.

Best Practices for Beginners in PLC Programming

Adopting good habits early in your PLC programming journey will save you significant time and frustration. Following a few simple best practices can make your code more readable, efficient, and easier to debug. One of the most important habits is to document your code thoroughly. Use comments and descriptions within the programming software to explain what each part of your program does.

Another key practice is to develop a structured and logical program flow. Avoid creating a single, massive block of code. Instead, break your logic down into smaller, manageable subroutines or sections, each responsible for a specific task. This modular approach makes troubleshooting much easier, as you can isolate and test individual parts of your program.

To get started on the right foot, keep these best practices in mind:

- Plan Your Logic: Before you start writing code, sketch out a flowchart of how your process should work.

- Use Meaningful Names: Give your inputs, outputs, and internal variables clear, descriptive names (e.g., "Motor_Start_Button" instead of "X001").

- Test Incrementally: Write and test small pieces of your program as you go, rather than writing the entire thing and trying to debug it all at once.

Advantages of Using PLCs in Automation

The widespread adoption of PLCs in industrial automation is due to the significant advantages they offer over older control methods. Their core benefits revolve around improved efficiency, greater flexibility, and superior reliability. The robustness of a PLC allows it to perform consistently in tough environments where other computers would fail.

Furthermore, PLCs enhance operational safety, with specialized safety PLC models available for critical applications that protect both personnel and equipment. Let's delve into how these controllers deliver improved efficiency and flexibility, as well as enhanced safety and reliability.

One of the greatest advantages of PLCs is the dramatic boost in operational efficiency they provide. By automating repetitive tasks, PLCs can run processes faster and more consistently than a human operator, leading to higher output and better product quality. Their ability to handle complex data and make decisions in real time allows for the optimization of machine cycles and the reduction of waste.

The flexibility of PLCs is another game-changing benefit. In the past, changing a manufacturing process meant a costly and time-consuming rewiring of control panels. With a PLC, the same change can often be accomplished by simply modifying the software program. This adaptability allows companies to quickly respond to changing market demands or reconfigure a production line for a new product.

This combination of speed and adaptability means that systems controlled by PLCs are not only more productive but also more future-proof. As processes evolve, the PLC can evolve with them.

Enhanced Safety and Reliability

Safety and reliability are paramount in industrial environments, and PLCs are designed with both in mind. Their robust design, featuring solid-state electronics with no moving parts, makes them inherently more reliable than mechanical relays. They are built to withstand the vibrations, temperature fluctuations, and electrical interference common on the factory floor, ensuring consistent performance and minimizing costly downtime.

For applications where failure could lead to serious harm, a specialized safety PLC can be used. These controllers have redundant processors and built-in diagnostics designed to meet stringent international safety standards. Using a safety PLC provides enhanced safety by reliably monitoring safety devices like emergency stop buttons and light curtains, and placing machinery into a safe state when a hazard is detected.

This focus on durable hardware and sophisticated safety logic makes PLC-based systems a dependable foundation for any automation strategy, protecting both your assets and your employees.

Skills and Certifications for Working with PLCs

As PLCs are central to modern industry, professionals with PLC skills are in high demand. For technicians, electricians, and plant engineers, the ability to install, program, and troubleshoot PLCs is a highly valuable asset. Meeting industry demands requires a combination of foundational knowledge and practical, hands-on experience.

To formalize these skills and stand out in the job market, many professionals pursue industry-recognized certifications. These credentials validate your expertise and demonstrate a commitment to your craft. Let's look at the essential knowledge areas and some of the available certifications.

Essential Knowledge Areas

To become proficient with PLCs, you need to build a solid foundation of essential knowledge. This goes beyond just knowing how to write code; it involves understanding the entire system. A strong grasp of basic electrical principles, including how to read schematics and wire control circuits, is a fundamental starting point.

On top of that, you need to develop strong programming skills. This means not only learning the syntax of PLC programming languages but also understanding how to apply them to solve real-world control problems. Familiarity with the principles of process control, including how to manage variables like temperature, pressure, and flow, is also critical for many applications.

Key knowledge areas and skills for PLC professionals include:

- Electrical Fundamentals: Understanding circuits, wiring, and schematic reading.

- PLC Programming Languages: Proficiency in Ladder Logic and familiarity with others like FBD and ST.

- Instrumentation and Process Control: Knowledge of sensors, actuators, and control theory.

- Networking: Understanding industrial communication protocols like EtherNet/IP.

Recognized Industry Certifications

While hands-on experience is invaluable, obtaining industry-recognized certifications can formally validate your skills and enhance your career prospects. These certifications show potential employers that you have met a certain standard of competency. Many of these credentials are offered directly by PLC manufacturers, focusing on their specific hardware and software platforms.

For example, Rockwell Automation offers a range of certifications for its Allen-Bradley family of controllers, while Siemens provides certifications for its SIMATIC PLCs. These vendor-specific training programs are highly respected in the industry because they meet the direct demands of companies using that equipment.

In addition to vendor-specific options, some technical schools and professional organizations offer more general PLC technician certifications.

These programs provide a broad overview of PLC theory and operation across multiple platforms.

- Vendor-Specific Certifications: (e.g., from Rockwell Automation, Siemens) demonstrate expertise on a particular platform.

- Certified PLC Technician Programs: Offered by various technical colleges and training institutions.

- Specialized Training: Courses focusing on specific areas like HMI/SCADA integration or industrial networking.

Conclusion

In conclusion, understanding automation PLCs is essential for anyone looking to enhance their skills in industrial control systems. By grasping the fundamentals of programmable logic controllers, their components, and programming basics, you can leverage the advantages that PLCs offer, such as improved efficiency and safety. As you embark on your journey into automation, remember to prioritize hands-on experience and seek out relevant resources to aid your learning. With the right approach, you can navigate the complexities of PLC systems and contribute significantly to the field of automation. Whether you're just starting or looking to deepen your knowledge, the world of PLC automation is full of opportunities waiting to be explored.

Frequently Asked Questions

What are the main functions of a PLC in industrial automation?

The main functions of a PLC in industrial automation are to monitor inputs from sensors, execute control logic based on its programmable logic, and control output devices like motors and valves. It is the core of control systems for machine automation and process control.

How is PLC programming typically done for automation tasks?

PLC programming is done using specialized programming software provided by the controller's manufacturer. Engineers write code in programming languages like Ladder Logic, Function Block Diagram, or Structured Text and then download it to the programmable controllers to execute the automation task.

How do you choose the right PLC for an automation project?

To choose the right PLC, you must assess the project's needs. Consider the number of I/O points, the complexity of the tasks, environmental factors like temperature ranges, and required communication protocols. Different programmable controllers are suited for different industries and applications.

What certifications or skills are needed to work with PLCs in industrial automation?

Essential skills include electrical knowledge, proficiency in PLC programming, and troubleshooting abilities. To meet industry demands, plant engineers often pursue certifications from PLC manufacturers like Rockwell Automation or Siemens, or complete formal PLC technician training programs to validate their skills.