Automation PLC: How It Transforms Industrial Processes

Key Highlights

- A Programmable Logic Controller (PLC) is a rugged industrial computer that forms the core of modern industrial automation.

- PLCs monitor inputs from sensors and machines, execute user-defined programs, and control output devices to manage industrial processes.

- Key components include a CPU, input/output (I/O) modules, a power supply, and communication interfaces.

- PLC programming is often done using ladder logic, but other languages like function block diagrams are also used with dedicated PLC programming software.

- These control systems offer significant advantages over older relay-based systems, including greater flexibility, reliability, and efficiency.

Introduction

Have you ever wondered what powers the precise, repetitive tasks in a modern factory? The answer often lies in a Programmable Logic Controller, or PLC. These specialized industrial computers are the workhorses of today's automation systems. Designed to withstand harsh industrial environments, a PLC uses programmable logic to control everything from simple machine functions to entire assembly lines. They bridge the gap between machinery on the plant floor and the control systems that supervise them, making complex industrial automation possible.

Defining Automation PLCs and Their Role in Industry

Automation PLCs, or programmable controllers, are essentially the brains behind automated industrial tasks. Their primary function is the control of machinery and processes, ensuring that operations run smoothly, accurately, and efficiently without constant human intervention. They are fundamental to industrial automation across countless sectors.

What sets these controllers apart is their robust design, which is specifically engineered for demanding factory settings. Unlike a standard PC, a PLC can handle vibrations, extreme temperatures, and electrical noise, making it a reliable choice for mission-critical applications. Now, let's explore what makes them so indispensable and where they are most commonly used.

What Makes a PLC Essential for Automation Systems

The primary reason a programmable logic controller is essential is its exceptional reliability. Built without moving parts like mechanical relays, PLCs are solid-state devices that can operate consistently for years in tough industrial conditions. This durability minimizes downtime and ensures the continuous performance of your automated system.

Another key advantage is flexibility. With traditional systems, changing a process required extensive and costly manual rewiring. A PLC, however, can be reprogrammed quickly and easily. This adaptability allows your control systems to evolve with changing production requirements, saving significant time and resources. You can modify logic and update operations without overhauling the physical hardware.

Furthermore, PLCs provide superior control and real-time monitoring. They are designed to execute complex logic with precise timing, simultaneously managing numerous inputs and outputs. This capability enables you to implement sophisticated automation strategies, improve efficiency, and maintain tight control over your processes through easy integration with other systems.

Common Applications of PLCs in Industrial Processes

PLCs are found at the heart of countless industrial applications, thanks to their versatility and power. They excel in any scenario that requires high-reliability control, process automation, and the monitoring of operational data from various input devices. Their ability to manage everything from simple start/stop functions to intricate motion control makes them invaluable.

From manufacturing floors to utility management, the use cases are extensive. You will find PLCs controlling robotic arms on an assembly line, managing the flow of ingredients in food processing, or overseeing the operations of a water treatment plant. They are the unseen force driving efficiency and precision in modern industry.

Some common industrial applications include:

- Manufacturing and Assembly: Controlling conveyor belts, robotic cells, and packaging machines.

- Process Control: Managing variables like temperature, pressure, and flow rates in chemical or food processing.

- Motion Control: Executing precise movements in CNC machines and automated material handling systems.

- Building Automation: Operating elevators, HVAC systems, and lighting in smart buildings.

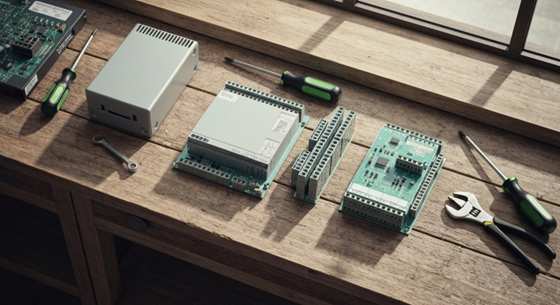

Key Components of a PLC System

A PLC system is not a single device but a collection of integrated components working together. At its core is the centralized processing unit (CPU), which runs the control logic. This CPU connects to various input devices and output devices through I/O modules.

A stable power supply provides the necessary direct current, while communication protocols enable the PLC to connect with other controllers, computers, and HMI screens. Understanding these individual parts is key to appreciating how the entire system functions. Let’s look at each of these core components in more detail.

Central Processing Unit (CPU) and Its Functions

The Central Processing Unit, or CPU, is the nerve center of the PLC. This powerful processing unit is responsible for executing the user-created program, performing logical operations, and managing all other functions within the controller. It acts like the PLC's brain, making decisions based on the inputs it receives.

Inside the CPU is programmable memory, where the operating system and the control program are stored. The CPU continuously reads the program from this memory to understand how to respond to different conditions. It is built with a robust design to handle the complex data and rapid calculations required for industrial control tasks.

The CPU operates in different modes, including a "run" mode where it actively executes the logic and a "program" mode where a user can download or edit the control program. This dual functionality allows for both active control and easy maintenance of the system's logic.

Input/Output (I/O) Modules and Signal Processing

Input/Output (I/O) modules are the bridge between the PLC's CPU and the industrial equipment on the factory floor. Input devices, such as sensors, switches, and buttons, connect to input modules. These modules convert the electrical signals from the devices into data that the CPU can understand.

Conversely, output modules take the decisions made by the CPU and convert them into output signals that control output devices. These devices can include electric motors, valves, lights, and alarms. The physical connection is typically made at terminal blocks on the I/O module.

I/O modules handle both digital and analog signals. Digital I/O is simple on/off communication, like a light switch. Analog I/O, on the other hand, represents a range of values, such as the variable speed of a motor or a temperature reading, allowing for more nuanced control.

Power Supply, Communication Modules, and Interfaces

The power supply is a critical component that converts the standard alternating current (AC) from the mains into the low-voltage direct current (DC) that the CPU and I/O modules require to operate. This ensures a stable and reliable power source, which is essential for consistent performance, especially in environments with electrical noise.

Communication modules expand the PLC's capabilities by enabling it to share data with other systems. These modules provide a physical connection to various industrial networks, allowing the PLC to communicate with other controllers, SCADA systems, and enterprise-level computers. A PLC's robust design allows it to function across wide temperature ranges.

Different communication protocols are used for different purposes, from connecting to devices on the plant floor to transmitting data over long distances.

| Protocol | Typical Use Case | Description |

|---|---|---|

| EtherNet/IP™ | Plant-wide control and data sharing | An industrial Ethernet protocol for connecting controllers, I/O, and other devices. |

| Modbus | General industrial communication | A simple, open serial protocol often used to connect with a wide range of industrial devices. |

| PROFIBUS/PROFINET | High-speed automation | A standard for fieldbus communication in automation technology, common in European systems. |

How a Programmable Logic Controller Operates

The operation of a programmable logic controller is defined by a continuous, cyclical process. This process, known as the scan cycle, involves three main steps: reading inputs, executing the program, and updating outputs. The PLC performs this cycle thousands of times per second to ensure real-time control.

During this operation, the PLC performs data acquisition from connected sensors and machines. It then processes this information according to its programming, which may be structured as ladder logic or sequential function charts. The following sections will break down this operational cycle and decision-making process.

The PLC Scan Cycle Explained

The PLC scan cycle is the fundamental process that allows the controller to operate. It begins with the Input Scan, where the PLC checks the status of all connected input devices and records their current state into its memory. This creates a snapshot of the machine or process at that exact moment.

Next is the Program Scan. During this step, the CPU executes the user-created control logic from top to bottom, one instruction at a time. It uses the input data gathered in the previous step to make decisions and determine what the corresponding output signals should be. This is where the core "thinking" of the control systems happens.

Finally, the Output Scan updates the state of all connected output devices based on the results of the program scan. After this, the PLC performs an internal diagnostics and communication check, a "housekeeping" step, before repeating the entire scan cycle. This loop runs continuously at very high speeds, enabling real-time control.

Types of PLCs Used in Automation

Not all automation tasks are the same, so PLCs come in different forms to meet diverse needs. The two primary categories you will encounter are fixed PLCs and modular PLCs. The main distinction between them lies in their construction and scalability. A fixed PLC is an all-in-one unit, while a modular PLC can be customized.

Choosing the right type from the available family of controllers depends on the complexity and scale of your application. Both offer easy integration into control systems, but their designs make them suitable for different scenarios. Let’s explore each type to see where they fit best.

Data Acquisition and Decision Making

Data acquisition is the first critical step in a PLC's decision-making process. The controller gathers information from two primary sources: automated system inputs from sensors measuring temperature or pressure, and user inputs from a human operator via a human-machine interface (HMI) or control panel.

This collected data provides a complete picture of the current state of the industrial process. Once the data is acquired, the PLC's CPU processes it according to the pre-programmed logic. This logic consists of a series of conditional statements that guide the controller's actions. For example, if a sensor detects that a tank is full, the program will decide to close an inlet valve.

This ability to perform rapid data acquisition and logical processing allows PLCs to manage complex operations with high precision. An automated system can react instantly to changing conditions, ensuring safety, quality, and efficiency without the need for direct human oversight for every action.

Programming PLCs for Industrial Automation

To make a PLC perform a specific task, you need to give it a set of instructions. This is done through PLC programming. Unlike general-purpose computer programming, PLC programming languages are designed specifically for industrial control applications, making them more accessible to engineers and technicians on the plant floor.

The most iconic of these programming languages is ladder logic, which visually resembles an electrical relay schematic. However, modern PLCs support a variety of methods, including function block diagrams and structured text. Let's examine these programming approaches and the tools used to implement them.

Popular PLC Programming Languages and Methods

While several PLC programming languages exist, a set of five has been standardized by IEC 61131-3 to ensure consistency across different hardware vendors. This standardization gives you more flexibility when designing and maintaining your control systems.

The most widely used language is Ladder Logic (LD). Its graphical format is intuitive for those with a background in electrical relays, as it represents logic in terms of rungs, coils, and contacts. However, other languages are often better suited for specific types of tasks, such as motion control or data handling.

Some of the most popular programming languages include:

- Ladder Logic (LD): A graphical language based on relay logic circuit diagrams.

- Function Block Diagrams (FBD): A graphical language that connects blocks of pre-defined functions.

- Sequential Function Charts (SFC): A graphical method for programming sequential processes, visualizing steps and transitions.

- Structured Text (ST): A high-level, text-based language similar to Pascal, ideal for complex algorithms.

PLC Software Tools and Simulation

Programming a PLC requires specialized PLC programming software provided by the hardware manufacturer. For example, Rockwell Automation offers the Studio 5000 Logix Designer® for its Logix family of controllers, while its Micro800 controllers use the Connected Components Workbench™ software. This programming software provides the environment for writing, editing, and downloading logic to the controller.

A key feature of modern PLC software is simulation. This allows you to test your control logic in a virtual environment before deploying it on the actual machinery. Simulation helps catch errors, validate process flows, and reduce commissioning time, ensuring the program works as expected without risking damage to expensive equipment.

This software also facilitates integration with higher-level systems. PLC programs can be designed to communicate seamlessly with Supervisory Control and Data Acquisition (SCADA) systems and HMIs. This connection enables operators to monitor processes, view data, and control machinery from a central interface.

Comparing PLCs to Traditional Relay Control

Before the invention of PLCs, industrial automation relied on hard-wired relay control systems. These systems used electromechanical relays to create logical circuits that controlled machine operations. While effective for their time, they were rigid, complex, and difficult to maintain.

The main difference between a modern PLC system and old-school relay control lies in software versus hardware. PLCs replaced thousands of physical wires and relays with a programmable processor, introducing unprecedented flexibility and advancing the capabilities of control systems. Let’s explore this evolution and its benefits.

Evolution from Relay Logic to PLCs

The shift from relay logic to PLCs began in the late 1960s. Industrial companies, particularly in the automotive sector, needed a more flexible and efficient way to control manufacturing processes. Relay logic systems were cumbersome; making a small change to a process often required days of work to manually rewire large panels of relays and timers.

This challenge led to the development of the first programmable controllers. The goal was to create a system that could be reprogrammed easily, reducing the downtime and cost associated with process modifications. Modern PLCs are the result of this innovation, offering a compact and powerful alternative to sprawling relay panels.

Today, a single PLC from a family of controllers can replace hundreds or even thousands of relays. The control logic, once physically wired, is now stored in a memory chip. This fundamental change revolutionized industrial automation, paving the way for the highly sophisticated and adaptable systems we use today. As Steve Hechtman, founder of Inductive Automation, noted, the industry needed to "solve SCADA pain points," a goal made possible by the programmability of PLCs. [Source: Inductive Automation, https://inductiveautomation.com/resources/article/plc-programmable-logic-controller]

Performance, Efficiency, and Flexibility Differences

The advantages of PLCs over traditional relays are clear and substantial. By replacing mechanical components with solid-state electronics and software-based logic, PLCs deliver a leap forward in machine performance, operational efficiency, and overall flexibility. This has allowed industries to tackle more complex operations than ever before.

One of the most significant benefits is the reduction in downtime. Troubleshooting a faulty relay in a complex panel could take hours, whereas PLC software includes diagnostic tools that can pinpoint issues in seconds. Furthermore, the easy integration of PLCs with other systems enables more connected and intelligent manufacturing environments.

Key differences that highlight PLC superiority include:

- Flexibility: Logic can be changed via software in minutes, not rewired over days.

- Reliability: Solid-state components have no moving parts to wear out or fail.

- Scalability: Adding new functions or I/O is far simpler than with relay panels.

- Advanced Capability: PLCs can handle complex operations like data logging, analog control, and communication.

- Reduced Size: A compact PLC replaces a massive cabinet of relays, saving valuable floor space.

Conclusion

In conclusion, automation using Programmable Logic Controllers (PLCs) is revolutionizing industrial processes by enhancing efficiency, reliability, and flexibility. As industries continue to evolve, the role of PLCs in automating complex tasks cannot be overstated. Their ability to integrate seamlessly with various components and programming languages makes them essential for modern manufacturing. Understanding the key components, operation methods, and applications of PLCs will empower businesses to leverage technology effectively. If you are looking to explore how PLCs can transform your operations, get in touch for a free consultation to discover tailored solutions for your specific needs.

Frequently Asked Questions

What certifications or skills are required to work with industrial PLCs?

Key skills include proficiency in PLC programming languages like ladder logic and an understanding of electrical schematics. Vendor-specific certifications from companies like Rockwell Automation or Siemens are highly valued, as is hands-on experience in industrial environments with their robust design constraints.

Which industries rely most on PLC-based automation?

Industrial automation using PLCs is critical in manufacturing, automotive, food processing, and pharmaceuticals. They are also essential in the energy and water/wastewater sectors for process control, often in harsh industrial environments or at remote locations where reliability is paramount.

How do you select the right PLC for your automation needs?

Choosing the right PLC system involves assessing your I/O count, processing speed, memory needs, and communication requirements. Consider a scalable family of controllers for future expansion and ensure easy integration with existing HMI or SCADA systems for a cohesive solution.