What Is Industry 4.0 and How Does It Work?

What Is Industry 4.0 and How Does It Work?

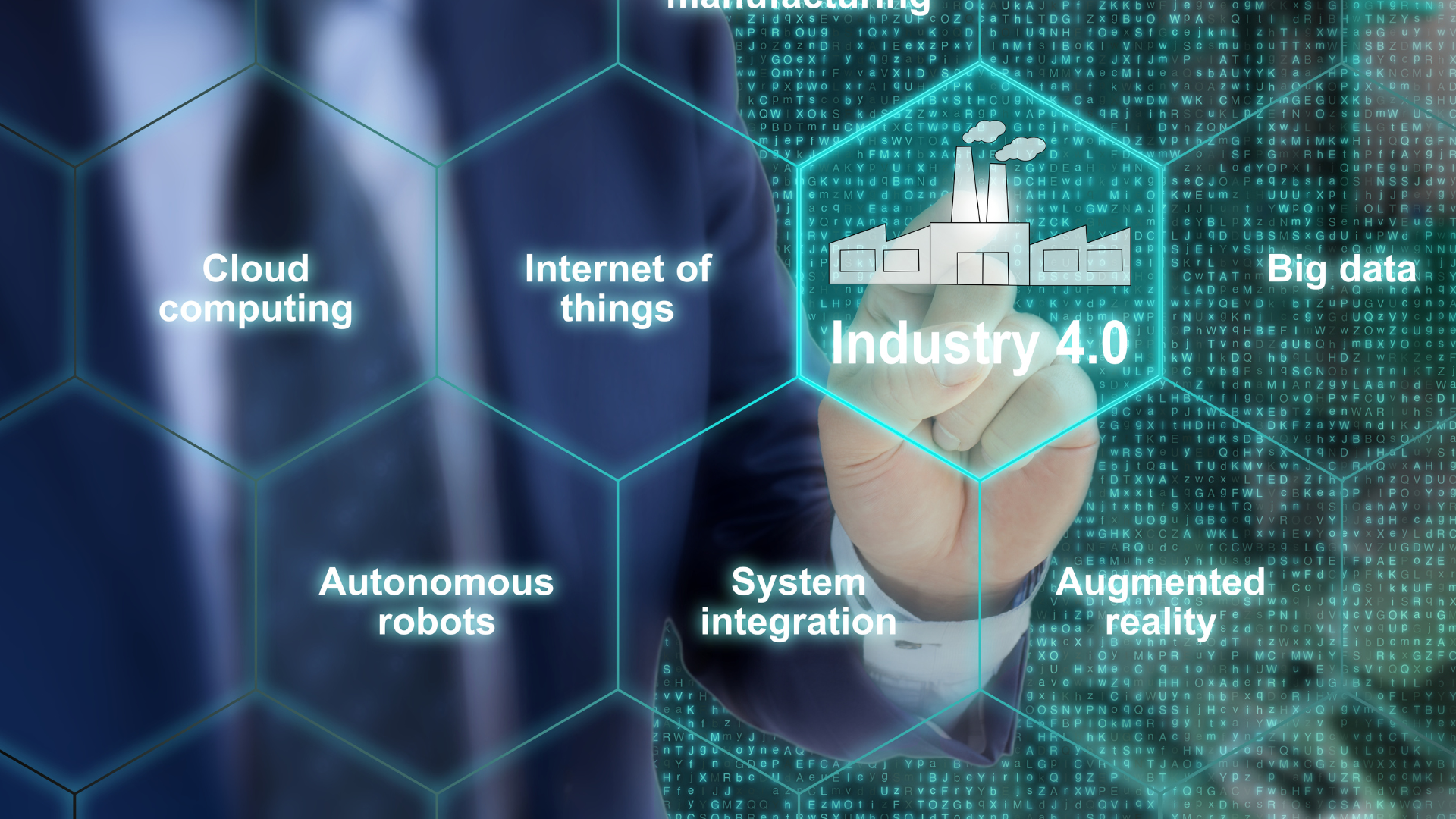

Industry 4. 0, often referred to as the fourth industrial revolution, is a powerful concept that encompasses the integration of advanced technologies into manufacturing processes. This transformation aims to create smart and interconnected systems that have the potential to revolutionize the way industries operate. By leveraging technologies such as artificial intelligence, Internet of Things (IoT), cloud computing, and big data analytics, Industry 4. 0 seeks to enhance efficiency, productivity, and overall competitiveness in various sectors. These cutting-edge technologies enable real-time data collection and analysis, predictive maintenance, autonomous systems, smart factories, and seamless communication between machines and humans. Through Industry 4. 0 initiatives, businesses can optimize their operations by harnessing the vast potential of digitalization and automation in order to stay ahead in today's rapidly evolving global markets. This revolution is characterized by the use of automation, data exchange, artificial intelligence, and the Internet of Things (IoT) in industrial settings.

Key impacts of the 4th Industrial Revolution

The Key impacts of the 4th Industrial Revolution are numerous. The integration of autonomous machines and systems that possess the capability to communicate with each other in real-time has proven to be a game-changer in terms of productivity and efficiency. This cutting-edge technology empowers organizations to streamline their operations by reducing manual intervention, enabling seamless collaboration between different components, and allowing for swift decision-making processes. By leveraging this advanced system, businesses can achieve higher levels of productivity while optimizing resource allocation and minimizing errors. The ability of these autonomous machines to communicate with one another in real-time fosters a synchronized workflow, resulting in improved overall efficiency throughout various industries. This leads to reduced downtime, improved quality control, and optimized resource allocation.

Examples of Industry 4.0 in Manufacturing

In the realm of manufacturing, the advent of Industry 4. 0 has ushered in a wave of transformative changes that cannot be overlooked. This fourth industrial revolution has revolutionized traditional manufacturing processes by leveraging advanced technologies such as artificial intelligence, internet of things (IoT), robotics, and data analytics. These cutting-edge tools enable manufacturers to enhance efficiency, optimize production processes, minimize waste, and improve overall productivity. The seamless integration of these technologies into the manufacturing ecosystem has paved the way for smart factories equipped with autonomous systems that can communicate and collaborate with each other in real-time. With Industry 4. 0 at the helm, manufacturers are now able to achieve unprecedented levels of automation, customization, flexibility, and agility in their operations. Furthermore, this paradigm shift empowers businesses to make data-driven decisions based on actionable insights derived from massive amounts of real-time data collected from various sources across the entire value chain. As a result, manufacturers can gain a competitive edge by improving product quality, reducing costs, shortening time-to-market cycles, and delivering superior customer experiences like never before. It is evident that Industry 4. 0 is not just a buzzword but rather an ongoing revolution that continues to redefine how modern manufacturing is conducted while opening up new possibilities for innovation and growth in various industry sectors worldwide. Examples include the use of robotics for assembly lines, predictive maintenance through IoT sensors monitoring machine performance, and data analytics for process optimization.

What Are the Industry 4.0 Standards?

In the world of Industry 4. 0, which represents the fourth industrial revolution, there are several key standards that encompass various aspects of advanced manufacturing and technology integration. These standards include interoperability, information transparency, technical assistance, and decentralized decision-making. Interoperability is a critical aspect of Industry 4. 0 as it ensures that different devices and systems can seamlessly communicate with each other. This allows for efficient data exchange and collaboration between different parts of the manufacturing process. By enabling smooth interoperability, companies can streamline their operations and optimize their productivity. Information transparency is another crucial element in Industry 4. 0. It involves providing real-time access to relevant data throughout the production process. With this level of transparency, decision-makers can have up-to-date insights into operations, enabling them to make informed decisions quickly and effectively. Technical assistance takes advantage of AI-powered systems to support human decision-making in Industry 4. 0 environments. These advanced systems analyze vast amounts of data in real-time, providing valuable insights and recommendations to aid human operators in making accurate decisions swiftly. Decentralized decision-making is a concept that empowers autonomous systems to make certain decisions independently within predefined boundaries. By distributing decision-making capabilities across different levels within an organization or even directly within machines themselves, companies can improve efficiency, responsiveness, and adaptability. Overall, these standards play a vital role in shaping the future of manufacturing by enhancing connectivity between devices, ensuring easy access to information at all levels, leveraging AI for better decision-making support, and empowering autonomous systems with decision-making capabilities within defined parameters

What Is Industry 4.0 in Simple Terms?

Industry 4. 0, in simple terms, denotes the revolutionary integration of cutting-edge technology into manufacturing processes. This integration aims to establish highly intelligent and efficient systems that possess the capability to seamlessly communicate with one another. By implementing advanced technologies such as Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), and robotics, Industry 4. 0 enables a new era of interconnectedness and automation in the manufacturing sector. As a result, productivity levels soar, costs are reduced, and overall operational efficiency is significantly enhanced.

How Does Industry 4.0 Affect Society?

The impact of Industry 4. 0, the fourth industrial revolution, goes far beyond its influence on manufacturing alone. Its transformative effects are felt across society as a whole, shaping various aspects of our lives. One significant consequence is the emergence of new job opportunities in fields such as data analytics and AI development. As industries embrace automation and digitalization, there is a growing demand for professionals skilled in these areas to navigate the complexities of this technological landscape. However, it is essential to recognize that Industry 4. 0 also necessitates workers to acquire new skills and adapt to changing roles within industries. As traditional job functions become automated or evolve alongside emerging technologies, individuals must be prepared to upskill or reskill themselves accordingly. This adaptability ensures they remain relevant and valuable contributors in an increasingly technology-driven work environment. Moreover, the influence of Industry 4. 0 extends beyond employment dynamics alone; it profoundly impacts how we live and interact within our communities at large. From smart cities that leverage interconnected devices for efficient resource management to improved healthcare systems utilizing AI-driven diagnostics, the implications are vast. In summary, Industry 4. 0 not only creates novel employment prospects but also demands a continuous learning mindset from workers as they navigate evolving roles within industries. Simultaneously, its influence extends into multiple facets of society, driving innovation and reshaping our lives for a more technologically advanced future. Additionally, it has implications for sustainability by enabling more efficient resource usage and reducing waste.

To learn more about Industry 4.0 in detail or view a presentation on it, you may refer to an industry 4.0 presentation PDF available online or seek out resources from reputable sources specializing in this topic.