Automation PLC Explained: Functions and Benefits

Key Highlights

- A Programmable Logic Controller (PLC) is a rugged industrial computer central to industrial automation.

- PLCs execute control systems by reading inputs from sensors and activating outputs like motors and valves.

- The core function revolves around a continuous scan cycle: reading inputs, executing programmable logic, and updating outputs.

- Key benefits include high reliability, flexibility for reprogramming, and scalability to meet changing process control demands.

- PLCs replaced older, hard-wired relay logic, offering easier maintenance and more complex data acquisition.

- They serve a wide range of industries, from manufacturing and food processing to energy and robotics.

Introduction

In the world of industrial automation, efficiency and reliability are paramount. At the heart of nearly every automated system is a powerful device known as a Programmable Logic Controller, or PLC. These specialized industrial computers are the brains behind the operation, designed to control machinery and processes with precision and durability. Unlike standard PCs, PLCs are built to withstand the harsh conditions of the factory floor, making them the backbone of modern manufacturing and process control. Are you ready to understand how these devices power our automated world?

Understanding PLCs in Automation Systems

Programmable Logic Controllers are essential tools in industrial automation, acting as the bridge between digital commands and physical actions. They are specifically designed to operate reliably in demanding industrial environments, enduring extreme temperatures, vibrations, and electrical noise that would cripple a standard computer. This robustness makes them indispensable for controlling everything from simple assembly lines to complex robotic cells.

Your understanding of automation is incomplete without knowing how these controllers function. They provide the intelligence for machinery, ensuring tasks are performed consistently and safely. We will explore the fundamental concepts behind PLCs and how they have evolved to become central to modern industry.

Definition and Core Concept of PLCs

A PLC is an industrial computer purpose-built for the control of machinery and manufacturing processes. At its core, the concept is simple: it monitors the status of input devices and makes decisions based on a custom program to control the state of output devices. This forms a foundational element of any industrial control system.

Imagine a sensor detecting a product on a conveyor belt. This is an input. The PLC receives this signal, processes it according to its programmable logic, and then sends a command—an output—to a robotic arm to pick up the product. This continuous loop of monitoring and responding allows for precise and repeatable automation.

This ability to manage electromechanical processes makes PLCs vital for industrial tasks. They don't just turn things on and off; they can manage complex sequences, timing, and logical operations, forming the foundation for sophisticated control of machinery. As one expert puts it, PLCs deliver "game-changing benefits for organizations around the world" by simplifying complex control.

[Source: https://inductiveautomation.com/resources/article/plc-programmable-logic-controller]

Historical Background and Evolution of PLC Technology

Before the advent of PLCs in the late 1960s, industrial control relied on hard-wired relay logic systems. These systems used a complex web of electromechanical relays to perform logical operations. While functional, they were cumbersome, difficult to modify, and required extensive manual rewiring for any process change, leading to significant downtime.

The invention of the PLC revolutionized the industry. It replaced the physical wiring of relays with software-based programmable logic stored in a microprocessor's memory. This meant that changing a control sequence no longer required a team of electricians to rewire panels; instead, a programmer could simply update the code.

This shift marked a significant leap forward. Modern PLCs have evolved far beyond their initial designs, becoming more powerful, compact, and capable of handling intricate communication and data processing tasks. Today's family of controllers offers a wide range of options, from small, standalone units to large, networked systems that manage entire factories.

Key Components of a PLC System

To appreciate how a PLC functions, it's important to understand its fundamental parts. A typical PLC system is not a single entity but a collection of components working in concert. These include a central processing unit (CPU), input and output (I/O) modules, a power supply, and a programming device.

Each component has a distinct role, from providing power and executing logic to interfacing with the physical world. The input devices and output devices connect to the PLC through I/O modules, often via terminal blocks, creating a complete control loop. Let's look closer at the CPU and the I/O system.

Central Processing Unit (CPU)

The Central Processing Unit (CPU) is rightfully called the brain of the PLC. This microprocessor is responsible for carrying out all the essential functions that make the system work. It executes the control program stored in its programmable memory, processes signals from inputs, and determines the appropriate actions for the outputs.

Functionally, the processing unit continuously runs a scan cycle. During this cycle, it checks the status of all inputs, runs the user-created logic, and updates the outputs accordingly. It also performs internal diagnostics and communicates with other devices, handling all the complex operations that automation requires.

The power of the CPU dictates the PLC's capabilities, such as its processing speed and the complexity of the tasks it can manage. A more powerful CPU can handle more I/O points, execute larger programs, and perform more sophisticated calculations, making it suitable for demanding, high-speed applications.

Inputs, Outputs, and I/O Modules

Inputs and outputs (I/O) are how a PLC interacts with the world. I/O modules provide the physical connection between the CPU and the machinery on the factory floor. Input devices, such as sensors, switches, and buttons, send electrical signals to the PLC to report the status of a machine or process.

These signals are received by input modules, which convert them into data the CPU can understand. After the CPU processes this data, it sends commands through output modules to output devices like motors, valves, solenoids, or indicator lights, causing a physical action to occur.

I/O modules come in two main types: digital (or discrete) and analog. Digital I/O operates like a simple switch (on/off), while analog I/O can handle a range of values, like temperature or pressure readings. This distinction allows PLCs to control a wide variety of devices with precision.

How a Programmable Logic Controller Works

The operation of a programmable logic controller is methodical and cyclical. Its entire process is built around what is known as the scan cycle. In this cycle, the PLC reads the status of its inputs, executes the program logic based on those inputs, and then updates the output signals accordingly.

This process happens at incredibly high speeds, often in milliseconds, allowing the PLC to control industrial processes in real time. This rapid, repetitive operation ensures that the system is always responsive to changes in the operating environment. The next sections will break down this scan cycle and how data is communicated.

PLC Operations and Scan Cycle

A PLC's functionality is defined by its scan cycle, a continuous four-step process. First is the input scan, where the PLC detects the state of all connected input devices and stores this input data in its memory. Are switches on or off? What is the current temperature reading?

Second, the PLC executes the user-programmed logic. Using the input data it just collected, the controller works through its program step-by-step to determine what the outputs should be. This is where the decision-making happens.

Third, the PLC performs an output scan, where it updates the state of all connected output devices based on the program's results. It sends output signals to turn motors on, open valves, or activate alarms. Finally, the PLC completes a housekeeping step, which includes internal diagnostics and communication tasks, before beginning the scan cycle all over again in real time.

Signal Processing and Data Communication

Beyond the basic scan cycle, effective signal processing and data communication are critical to a PLC's function. The controller must accurately interpret a variety of electrical signals from inputs, which can range from simple on/off states to complex analog values that represent pressure, speed, or temperature.

Once processed, this information often needs to be shared. PLCs use various communication protocols to talk to other devices, such as other PLCs, HMIs (Human-Machine Interfaces), or higher-level SCADA systems. Common protocols include Modbus, EtherNet/IP, and Profinet, which allow for seamless data exchange across the plant network.

This ability to handle complex data and communicate it effectively is what elevates a PLC from a simple controller to a powerful automation tool. It enables real-time monitoring, data logging, and integration into larger, enterprise-wide systems, providing valuable insights into the manufacturing process.

Types of PLCs Used in Automation

Not all automation tasks are the same, so PLCs come in different forms to meet diverse needs. The two primary categories you will encounter are fixed PLCs and modular PLCs. The main distinction between them lies in their construction and scalability. A fixed PLC is an all-in-one unit, while a modular PLC can be customized.

Choosing the right type from the available family of controllers depends on the complexity and scale of your application. Both offer easy integration into control systems, but their designs make them suitable for different scenarios. Let’s explore each type to see where they fit best.

Fixed (Compact) PLCs

Fixed PLCs, also known as compact PLCs, are self-contained units that integrate the processor, power supply, and a specific number of inputs and outputs into a single housing. As the name suggests, the number of I/O points is fixed and cannot be expanded, though some models allow for limited additions.

These controllers are an excellent choice for smaller, standalone applications where the control requirements are well-defined and unlikely to change. Their compact size and lower cost make them ideal for simple machine control, such as a conveyor system or a small packaging machine.

Despite their simplicity, compact PLCs are built to be rugged and reliable, capable of withstanding the same harsh industrial environments as their larger counterparts. Their all-in-one design allows for easy integration and straightforward installation, making them a popular option for simple, cost-effective automation.

Modular PLCs

Modular PLCs are designed for flexibility and scalability. They consist of a base rack or chassis into which you can plug various modules, including a CPU, power supply, and different types of I/O modules. This allows you to build a controller that is perfectly tailored to the specific needs of your application.

The key advantage of modular PLCs is their scalability. If your process expands or your requirements change, you can easily add more I/O, upgrade the CPU, or add specialized modules for functions like communication or high-speed counting. This makes them ideal for large, complex, and evolving automation systems.

This design also simplifies maintenance. If a single module fails, you can replace it without disrupting the entire system. Their adaptability makes them suitable for controlling entire production lines or processes in remote locations where flexibility is essential.

Main Functions of PLCs in Industrial Automation

PLCs are the workhorses of industrial automation, performing a wide range of functions far beyond simple on/off commands. Their primary roles include sequential control, motion control, and continuous process control. They execute logic based on programmed instructions, often using languages like ladder logic or sequential function charts.

These controllers are also central to monitoring industrial systems, gathering data on machine performance and process variables. This dual capability of both controlling and monitoring makes them indispensable. Let's examine these key functions more closely.

Monitoring and Control Functions

A core function of any PLC is real-time monitoring of industrial processes. PLCs continuously gather data from sensors and other input devices to track variables like temperature, pressure, flow rate, and machine status. This constant stream of information provides a live view of what is happening on the factory floor.

This monitoring capability is directly tied to control. Based on the incoming data, the PLC makes decisions to keep the process within its desired parameters. This is a form of supervisory control, where the PLC automatically adjusts operations to maintain efficiency and quality. For example, it can speed up or slow down a motor to maintain a consistent production rate.

The data collected by the PLC is also invaluable for diagnostics and performance analysis. By tracking machine performance over time, you can identify potential issues before they cause a breakdown, schedule predictive maintenance, and optimize your overall operations for better productivity.

Sequential and Logic Operations

At its heart, a PLC is a logic-solving device. Its primary job is to execute sequential and logic operations based on a pre-written program. The most common programming language used for this is ladder logic, which uses a graphical format that resembles the electrical schematics of old relay circuits, making it intuitive for electricians and technicians.

However, modern PLCs support several other standard programming languages. These include function block diagrams (FBD), which represent functions as blocks, and sequential function charts (SFC), which are excellent for programming processes with distinct steps. Structured Text (ST), a high-level language similar to Pascal, is used for complex mathematical or data-handling tasks.

This variety of programming options allows developers to choose the best language for the task at hand. Whether it's a simple start-stop sequence or a complex batching process, the PLC executes the logic operations with speed and precision, ensuring the automated system performs exactly as intended.

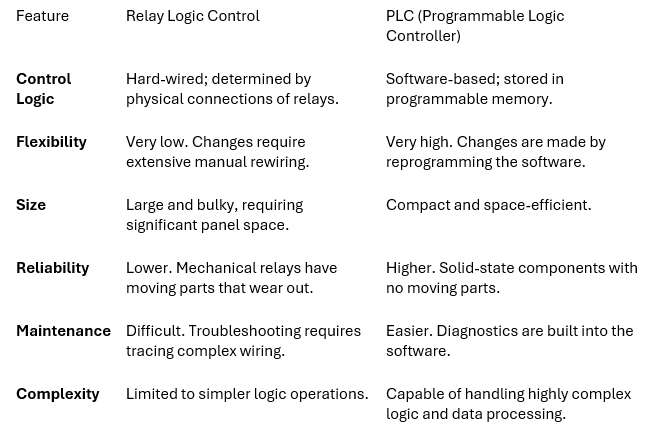

Comparing PLCs and Traditional Relay Logic Control

To fully appreciate the advantages of PLCs, it is helpful to compare them to what they replaced: traditional relay logic control systems. Before PLCs, industrial control was achieved through a physical network of electromechanical relays, timers, and counters, all hard-wired together to perform a specific task.

The main difference is flexibility. Altering a relay-based system required extensive and time-consuming manual rewiring by a human operator. In contrast, a PLC can be reprogrammed in software, a much faster and more efficient process. This fundamental shift from hardware to software transformed industrial control.

Differences in Operation and Design

The differences in operation and design between PLCs and relay logic are significant. Relay logic systems are hardware-based, with their control logic determined by the physical wiring of components. Programmable controllers, on the other hand, are software-based, with their logic stored in a digital program.

This leads to vast differences in complexity, size, and maintenance. A relay panel for a moderately complex task could take up a large cabinet, filled with hundreds of wires. The same task can be handled by a compact PLC, dramatically reducing the physical footprint and simplifying the wiring to just the I/O devices.

The table below highlights the key distinctions in their design and operation, illustrating why programmable controllers became the industry standard.

Advantages and Limitations

The advantages of PLCs over relay logic are clear. Their reliability is significantly higher because they are solid-state devices with no moving parts to wear out or fail. This robust design ensures consistent performance and less downtime. Furthermore, the ability to easily reprogram a PLC provides immense flexibility to adapt to new production requirements.

Another key benefit is the easy integration with other systems. PLCs can communicate with computers, HMIs, and other controllers, enabling sophisticated, plant-wide automation. Their troubleshooting capabilities are also superior; built-in diagnostics can quickly pinpoint faults, whereas finding a problem in a complex relay panel was a painstaking process.

However, PLCs are not without considerations. Their initial cost can be higher than a simple relay circuit for very small tasks. They also require specialized knowledge for programming and maintenance, which is a different skill set than traditional electrical wiring. Despite this, for nearly all industrial applications, the advantages of PLCs far outweigh these limitations.

Benefits of Implementing PLCs in Automation Projects

Implementing PLCs in your automation projects unlocks a host of powerful benefits that drive efficiency and productivity. Chief among these are enhanced reliability, flexibility, and scalability. Unlike older systems, PLCs can be easily adapted to changing needs, ensuring your investment remains valuable for years to come.

The advantages extend to maintenance and operational oversight, as PLCs provide valuable diagnostic data that simplifies troubleshooting and reduces downtime. This combination of robust performance and adaptability makes them a cornerstone of modern automation. Let’s explore these benefits in more detail.

Flexibility and Scalability

One of the most significant benefits of using PLCs is their inherent flexibility. A PLC's logic is defined by its program, not its physical wiring. This means you can change a machine's entire sequence of operations by simply downloading a new program, without any need for costly and time-consuming hardware modifications. This adaptability is crucial in today's fast-changing manufacturing landscape.

This flexibility is paired with exceptional scalability. As your production needs grow, your control system can grow with you. With modular PLCs, you can add more I/O points, more powerful processors, or specialized function modules to handle new tasks. This robust design ensures that your system can evolve with industry demands.

The benefits of PLC flexibility and scalability include:

- Faster Changeovers: Reprogramming is quicker than rewiring, reducing downtime between production runs.

- Future-Proofing: Systems can be easily upgraded to accommodate new technology or increased capacity.

- Cost-Effective Expansion: You only need to add the specific modules required, rather than replacing the entire system.

- Easy Integration: PLCs can readily connect with new machines and enterprise-level software.

Reliability, Safety, and Maintenance

PLCs are renowned for their exceptional reliability. Designed as solid-state devices with no moving parts, they are built to operate flawlessly for long periods in tough industrial settings. This durability minimizes unexpected failures and production stoppages, leading to greater overall efficiency. For critical applications, specialized safety PLCs are used to ensure processes fail in a predictable and safe manner.

This reliability also simplifies maintenance. PLCs come with built-in diagnostic and fault-finding tools. When an issue occurs with a connected component, like one of the electric motors or a sensor, the PLC can pinpoint the exact source of the problem. This allows technicians to resolve issues quickly instead of spending hours manually tracing wires and testing components.

As Rockwell Automation, a leading PLC manufacturer, notes, their controllers are "built to withstand harsh industrial environments, including extreme temperatures, vibrations, and industrial noise." [Source:

https://www.rockwellautomation.com/en-us/products/hardware/allen-bradley/programmable-controllers.html] This robust engineering ensures consistent performance and lowers long-term maintenance costs, making them a dependable choice for any automation project.

Conclusion

In conclusion, understanding and implementing Programmable Logic Controllers (PLCs) can revolutionize your automation processes. With their ability to offer flexibility, reliability, and enhanced safety measures, PLCs stand out as indispensable tools in modern industrial settings. By comparing PLCs with traditional relay systems, it becomes evident how much more efficient and manageable automation projects can become. Whether you're looking to streamline operations or enhance your system's capabilities, embracing PLC technology can lead to significant improvements. If you're ready to take the next step, don’t hesitate to get a free consultation to explore how PLCs can benefit your specific automation needs.

Frequently Asked Questions

Which industries commonly use PLC-based automation systems?

PLCs are used across nearly all industrial applications. Key sectors include manufacturing, automotive, food processing, pharmaceuticals, energy, and water treatment. They manage control systems for everything from simple machines to complex processes in factories and even at remote locations.

How do you choose the right PLC for an automation project?

Choosing the right PLC involves assessing your project's needs. Consider the number of inputs and outputs required, the complexity of the process control, and the need for future scalability. This will help you decide between compact PLCs for smaller tasks and modular PLCs for larger systems.

What skills or certifications are needed to work with PLCs?

Working with PLCs requires skills in PLC programming, primarily in languages like Ladder Logic. Familiarity with specific PLC programming software from vendors like Rockwell Automation or Siemens is essential. While not always required, vendor-specific certifications can demonstrate a high level of expertise.