Mastering Automation PLC: Your Path from Novice to Expert

Key Highlights

- Programmable logic controllers (PLCs) are central to industrial automation, streamlining control of machinery and complex industrial processes.

- PLC programming, especially with ladder logic, allows easy adaptation of automation systems across diverse industrial applications.

- Input devices and output devices are coordinated by the PLC to manage and optimize production lines.

- PLC systems offer reliable control functions and diagnostics for improved system health and efficiency.

- Modern PLC architecture, including modular and fixed types, ensures scalability and flexibility in automation projects.

- Industrial automation relies on PLCs for precise control, real-time monitoring, and seamless integration with advanced industrial processes.

Introduction

Across today’s manufacturing and process industries, industrial automation forms the backbone of efficient operations. At the heart of this modern revolution lies the PLC system, a powerful solution for controlling and monitoring machines and equipment. Programmable controllers have evolved to become indispensable in streamlining industrial tasks, reducing downtime, and increasing productivity. Whether you’re just exploring automation or seeking to optimize complex systems, understanding PLCs is crucial for achieving smarter, safer, and more reliable industrial automation.

Understanding PLC Automation: Fundamentals and Evolution

PLC automation uses programmable logic controllers to manage and control industrial processes, making automation systems smarter and more adaptable. These controllers, first developed by Bedford Associates in the late 1960s, replaced clunky relay-based control systems and sparked a new era in industrial automation. Over time, PLCs have become more advanced, integrating powerful processing units and supporting complex control functions across various industries.

Learning the fundamentals of PLC automation helps you see how control systems evolved—from simple relay panels to today’s networked, intelligent controllers. This foundational knowledge sets the stage for exploring the key features and benefits of PLCs.

What Is a Programmable Logic Controller (PLC)?

A programmable logic controller (PLC) is an industrial digital computer designed for automation of electromechanical processes. It monitors inputs, makes decisions based on its program, and controls outputs to execute specific tasks, enhancing efficiency and reliability in manufacturing and production environments.

Historical Development of PLCs in Industrial Automation

The birth of the programmable controller traces back to Bedford Associates in the late 1960s, when General Motors sought a better solution for automating assembly lines. Early PLCs replaced hard-wired relay logic, offering programmable control and easier system modifications, which proved revolutionary for the automotive and manufacturing industries.

As programmable controllers matured, they were rapidly adopted across various industrial applications. Industries benefited from safer processes, reduced wiring complexity, and more reliable control functions, all while gaining the ability to reprogram systems with ease for new products or processes.

Today, PLCs are the cornerstone of industrial automation. Their role continues to expand, integrating advanced features such as remote monitoring, motion control, and connectivity with modern supervisory control and data acquisition (SCADA) systems—providing you with smarter, more efficient factories.

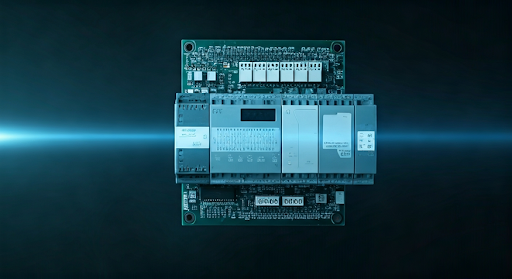

Key Components and Architecture of a PLC System

Central to any PLC system are its major components: the power supply, processing unit (CPU), I/O modules, and communication modules. These form the backbone of the automation system’s architecture, connecting field devices to the digital world and enabling precise control of industrial processes.

Exploring how each module interacts helps you understand how PLCs process input signals, execute logic, and deliver output commands. This architecture is what allows PLCs to adapt to a variety of applications and integrate seamlessly into modern industrial networks.

Power Supplies, CPUs, and I/O Modules Explained

The power supply in a PLC system converts incoming voltage into stable levels required by the processing unit and attached modules. This ensures continuous, reliable operation even amid fluctuating industrial power conditions.

At the core sits the processing unit (CPU), executing user programs and controlling workflow by reading data from input modules—devices like switches, sensors, and analog inputs. It processes this information in real time, applying logic to determine which output modules should activate motors, relays, or other output devices.

I/O modules serve as the PLC’s interface with the physical world:

- Digital input modules gather on/off signals from switches and sensors.

- Analog input modules capture variable data, such as temperature or pressure.

- Output modules deliver electrical signals to control external devices. Understanding these components is crucial for building a robust, scalable, and responsive automation system.

Communication Modules and Network Integration

Communication modules connect PLCs with other control systems, SCADA, and remote devices using protocols like Ethernet, Modbus, or Profibus. These modules serve as the physical connection, allowing the PLC to send and receive data across networks and integrate with broader automation systems.

With network integration, PLCs can be managed from remote locations, enabling real-time diagnostics, monitoring, and program updates without onsite intervention. This flexibility is essential for large facilities or distributed production sites.

Enhancing communication capabilities improves both reliability and efficiency. Factories benefit from quick error detection, timely response to changing conditions, and centralized management of multiple automation systems—resulting in smoother workflows and reduced downtime.

Core Functions and Features of PLCs in Automation

PLCs form the heart of modern control systems, driving automation by executing programmed logic, monitoring system health, and managing input and output devices. Core functions like output control, diagnostics, and fault detection help you maintain safe, efficient operations.

These controllers use function block diagrams, ladder logic, or textual programming languages to define automated sequences, ensuring predictable results. With features for continuous monitoring and diagnostics, PLCs keep automation systems responsive and reliable in demanding industrial environments.

Input Processing and Output Control

A PLC automation system excels at interpreting input signals and generating precise output commands. It continuously scans signals from input devices, such as sensors and switches, to detect changes in the industrial process.

Once inputs are processed, the PLC applies programmed logic to decide how and when to activate output devices. This could mean starting a motor, opening a valve, or triggering an alarm—all at exactly the right moment. The main difference between PLC automation and older relay-based systems is speed, accuracy, and adaptability.

Key elements include:

- Real-time input processing for quick detection and response.

- Output control that ensures safety, efficiency, and consistency.

- Flexible programming for easy modification of control sequences.

- Scalability, allowing easy addition of new devices or output modules as your needs grow. This approach allows you to automate everything from complex machinery to simple assembly line tasks effortlessly.

Monitoring, Diagnostics, and Fault Detection

Continuous monitoring is built into every PLC automation system, ensuring critical data is collected and analyzed for optimal performance. Diagnostics routines run automatically, checking system health and pinpointing faults as soon as they arise.

"PLCs empower maintenance teams to spot and address issues before they cause downtime," says John Smith, industrial automation expert.

Key benefits include:

- Integration with SCADA systems for real-time visibility.

- Built-in diagnostics for early fault detection.

- Safety PLC features for protecting equipment and personnel.

- Remote monitoring to ensure immediate response to alarms or failures. These capabilities mean fewer unexpected shutdowns, faster repairs, and safer operations. Your team can rely on the automation system to alert them to problems, helping keep production lines running smoothly.

Types of PLCs and Their Industrial Applications

Two primary PLC types—modular and fixed—offer solutions for a wide variety of industrial applications. Modular PLCs suit complex or expanding systems, whereas fixed PLCs are ideal for simpler, cost-sensitive automation projects. Both play vital roles in process control, food processing, and assembly lines.

Selecting the right type depends on your application’s size, required flexibility, and plans for future growth. These options ensure you have the right automation system for every environment and task.

Fixed vs. Modular PLCs: Pros, Cons, and Use Cases

Fixed (or compact) PLCs combine the CPU, power supply, and I/O modules into a single unit. They are economical, simple to install, and perfect for straightforward control systems with limited expansion requirements. Modular PLCs, on the other hand, let you add or replace I/O and communication modules to tailor the system for complex or growing applications.

When choosing, consider scalability, space, and the ability to withstand wide temperature ranges or electrical noise.

| Type | Pros | Cons | Use Cases |

|---|---|---|---|

| Fixed PLC | Cost-effective, easy setup, compact | Limited expansion, fixed I/O count | Small machines, simple lines |

| Modular PLC | Scalable, flexible, easy to upgrade | Higher initial cost, larger footprint | Large plants, evolving systems |

Your decision should balance current needs with future adaptability, ensuring your automation solution lasts.

PLCs in Manufacturing, Process Control, and Specialized Fields

PLCs are everywhere in industrial automation, from manufacturing to highly specialized environments. In manufacturing, PLCs coordinate assembly lines, manage electric motors, and handle process control for consistent product quality.

In process industries, PLCs handle critical tasks like temperature control in food processing, real-time monitoring in chemical plants, and motion control in robotics. They also support safety PLC functions in hazardous environments.

For instance, food processing plants depend on PLCs for precise mixing, timing, and temperature regulation. In automotive factories, PLCs orchestrate robotic assembly, welding, and painting. Even specialized applications—like water treatment or renewable energy—rely on PLCs to automate monitoring and control for remote locations.

PLC Programming Essentials for Beginners and Experts

Mastering PLC programming is essential for anyone working with automation systems. Whether you’re just starting or looking to advance, you’ll use programming software and a programming device to write custom instructions in various PLC programming languages.

Modern PLCs support easy-to-use graphical and textual languages, making it straightforward to design, test, and modify automation logic. Understanding these tools gives you the power to optimize processes, reduce downtime, and adapt to new industrial challenges.

Common Programming Languages: Ladder Logic, Structured Text, and More

PLCs are typically programmed using several languages, each suited to different tasks. The most common is ladder logic, which visually resembles relay circuits and is favored for its simplicity and clarity.

Other popular PLC programming languages include:

- Structured Text: A high-level, textual language ideal for complex calculations or data handling.

- Function Block Diagram: A graphical language for visualizing control logic as interconnected blocks.

- Instruction List and Sequential Function Chart: Less common, but useful for advanced or legacy systems.

Ladder logic remains the go-to for most industrial applications, offering a gentle learning curve for beginners. Structured Text and function block diagrams are gaining popularity in complex or data-driven environments, giving expert programmers greater flexibility and power.

Simulation, Testing, and Troubleshooting PLC Programs

Before deploying a PLC program, it’s critical to simulate and test your logic using PLC programming software. Simulation tools replicate real-time input and output conditions, allowing you to validate control sequences, catch errors, and ensure safety before the code runs on actual hardware.

Testing also means checking how the system handles complex data, fault conditions, and edge cases. Modern PLCs support real-time diagnostics for ongoing monitoring during live operation, helping you troubleshoot and refine your program as needed.

Regular troubleshooting keeps automation systems running smoothly. By leveraging built-in tools, you can identify issues quickly, minimize downtime, and maintain high levels of performance across your industrial processes.

Choosing the Right PLC for Your Automation Project

Finding the ideal PLC for your automation system depends on matching performance, scalability, and environment to your project’s requirements. Selection criteria include output modules, processing power, and the specific needs of your industrial application.

Evaluating the working environment, expected growth, and integration options ensures your automation system remains robust and flexible. By considering these factors, you’ll build a foundation for reliable, future-proof control of your machinery and processes.

Key Selection Criteria: Performance, Scalability, and Environment

Selecting a PLC involves balancing several important criteria to suit your automation needs. Performance is key—ensure the PLC can process logic fast enough for real-time control. Scalability matters if your automation system might expand, so choose a system with flexible I/O and communication modules.

Environmental factors also play a role:

- Can the PLC operate across the required temperature ranges?

- Is it resistant to electrical noise, vibration, or dust?

- Does it offer redundant modules for high-availability operations?

- Are output modules easily expandable as your process grows?

By answering these questions, you’ll ensure the PLC you select can withstand industrial conditions, support future upgrades, and deliver reliable, high-speed control across your automation projects.

Comparing PLC Automation to PC-Based and Relay-Based Systems

PLC automation systems stand apart from PC-based and relay-based solutions. Relay-based systems use physical switches and wiring, offering basic control but limited flexibility, slow operation, and complex troubleshooting. PC-based systems deliver greater flexibility and computing power, but often lack the ruggedness, reliability, and real-time performance needed for harsh industrial environments.

Key differences include:

- PLCs are purpose-built for industrial control, with fast response and high reliability.

- PC-based automation can handle complex data but may struggle with industrial noise and environmental stress.

- The main difference with relay systems is the speed, scalability, and ease of programming.

- PLCs typically serve as the primary automation method in modern factories due to their superior durability and support for advanced communication protocols.

Choosing PLCs ensures your control system is robust, adaptable, and ready for industry demands.

Conclusion

In conclusion, mastering PLC automation requires a comprehensive understanding of its fundamentals, components, and applications. As you journey from novice to expert, remember that the effectiveness of a PLC system lies in its ability to streamline operations, enhance efficiency, and adapt to various industrial needs. Embracing programming essentials and choosing the right PLC for your project can significantly impact the success of your automation endeavors. With the knowledge you’ve gained from this blog, you are well-equipped to tackle challenges in the realm of PLC automation. If you're looking for personalized guidance or support in your PLC projects, get in touch with us for a free consultation.

Frequently Asked Questions

Which industries benefit most from PLC automation?

Industries such as manufacturing, food processing, process control, and assembly lines gain the most from PLC automation. These sectors rely on automation systems for precise, real-time control, improved efficiency, and reliable production, making PLCs an essential tool for modern industrial automation.

What are some real-world examples of PLC-controlled automation tasks?

Typical PLC-controlled tasks include activating output devices for temperature control in food processing, managing electric motors on conveyor systems, and supervising control systems on assembly lines. Output modules allow customization for each application, ensuring efficient and reliable industrial processes.

How does PLC automation improve reliability and efficiency in factories?

PLC automation increases reliability by providing real-time monitoring, instant diagnostics, and robust control of machinery. This enhances efficiency by enabling quick response to changes, reducing downtime, and maintaining consistent, high-quality production across all factory processes.