Automation PLC: Key Features and Benefits Explained

Key Highlights

- A Programmable Logic Controller (PLC) is a rugged industrial computer that automates and controls machinery and processes. Recent trends and innovations in PLC technology for automation include enhanced connectivity with Industrial Internet of Things (IIoT) devices, improved real-time data processing, and integration with cloud-based monitoring platforms. Modern PLCs are being designed with advanced cybersecurity protocols and flexible programming environments to support complex control tasks. The core of a plc system includes a central processing unit (CPU), input/output (I/O) modules, and a power supply.

- The core of a plc system includes a central processing unit (CPU), input/output (I/O) modules, and a power supply.

- PLCs are programmed using languages like ladder logic and function block diagrams to execute specific tasks. In real-world applications, PLCs are widely used in industrial automation for controlling conveyor belts, assembly lines, and robotic arms in manufacturing plants. In home automation, PLCs can manage systems such as lighting, HVAC, and security controls, providing reliable and flexible automation solutions. Key benefits of using PLCs in industrial automation include high reliability, flexibility, scalability, and ease of maintenance.

- Key benefits of using PLCs in industrial automation include high reliability, flexibility, scalability, and ease of maintenance.

- They form the foundation of modern control systems, integrating seamlessly with HMIs and SCADA systems.

- PLCs come in various types, such as fixed, modular, compact, and rack-mounted, to suit different application requirements.

Introduction

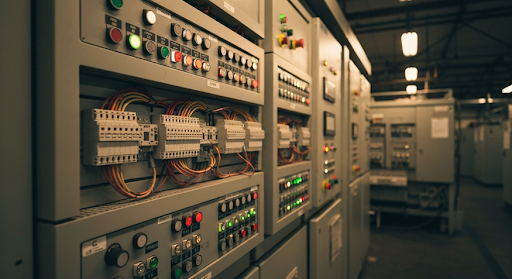

If you are involved in industrial automation, you have likely encountered the term Programmable Logic Controller, or PLC. These devices are the workhorses of modern manufacturing and process control, acting as the brains behind automated operations. A PLC is an industrial-grade computer designed to control and monitor equipment based on custom programming. From simple machine functions to entire production lines, these powerful control systems are essential for achieving efficiency, precision, and reliability in today's automated world.

Understanding PLCs in Automation

At its core, a programmable logic controller is a specialized computer built to withstand harsh industrial environments. Unlike standard computers, they are designed for the specific purpose of managing electromechanical processes. This makes them a fundamental component of industrial automation.

How does a PLC actually function within these systems? It operates in a continuous cycle of reading inputs from sensors and devices, executing a user-written program based on that information, and then updating outputs to control machinery like electric motors or valves. This simple yet powerful operational loop is the key to automating complex industrial tasks.

Definition of Programmable Logic Controllers

This is paragraph text. Click it or hit the Manage Text button to change the font, color, size, format, and more. To set up site-wide paragraph and title styles, go to SitA programmable logic controller (PLC) is a type of industrial computer specifically designed for the control of manufacturing processes. Think of it as the central nervous system for machinery on a factory floor. It receives information from connected sensors or input devices, processes the data, and triggers outputs based on its pre-programmed parameters.

The main difference between a PLC and a standard desktop computer lies in its rugged construction and its dedicated function. PLCs are built to survive extreme temperatures, vibration, and electrical noise common in industrial settings. Their entire architecture, from hardware to the operating system, is optimized for real-time control tasks.

This specialization makes plc programming and operation highly reliable for critical applications. Instead of running multiple applications, a PLC focuses solely on executing its control logic with speed and precision, ensuring that automated processes run smoothly and safely.

Role of PLCs in Industrial Automation

In the landscape of industrial automation, PLCs serve as the primary control mechanism for a vast range of applications. They are the essential link between the physical machinery and the digital control logic that governs its behavior. Their role is to translate programmed instructions into physical actions, orchestrating everything from assembly lines to complex chemical reactions.

Before the invention of PLCs in the late 1960s, automation relied on complex, hard-wired relay systems. These systems were difficult to modify and troubleshoot. PLCs revolutionized the industry by offering a flexible, software-based solution. Now, changes to a process can be made by simply reprogramming the controller, a significant improvement in efficiency.

Today, PLCs are indispensable for process control. Whether managing the sequence of operations on an automotive assembly line or regulating temperatures in a food processing plant, these control systems provide the precision and reliability needed for modern manufacturing.

Basic Components and Architecture of a PLC System

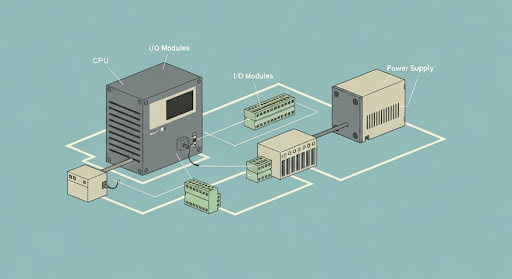

To truly understand how a PLC works, it is helpful to look at its fundamental building blocks. A typical plc system is composed of several key components working together to execute control tasks. These core elements form the basic architecture that allows a PLC to receive, process, and transmit signals.

The main components include the central processing unit (CPU), memory, input/output (I/O) modules, and a power supply. The CPU acts as the brain, the memory stores the program, and the I/O modules provide the physical connection to the machinery. Let’s explore each of these parts in more detail.

Central Processing Unit (CPU)

The Central Processing Unit (CPU) is the brain of the plc system. This microprocessor-based processing unit is responsible for executing the user-created control program, performing logical operations, and managing communications between all other PLC components. It is where the decision-making happens.

During operation, the CPU continuously reads the status of input devices, executes the program logic stored in its memory, and then updates the output signals accordingly. It carries out these steps in a repetitive loop, known as the scan cycle, ensuring that the controller responds to changes in the system in real time.

Beyond program execution, the CPU also performs internal diagnostics and facilitates communication with programming devices and other systems. Its speed and processing power are critical factors that determine the PLC's ability to handle complex tasks like high-speed data acquisition and motion control.

Power Supply and Input/Output Modules

A stable and reliable power supply is essential for any PLC to function correctly. This component converts the main AC voltage into the low-voltage DC power required by the PLC's internal components, such as the CPU and memory. It ensures that the controller operates consistently, even with fluctuations in the plant's electrical grid.

The input/output (I/O) modules are the bridge between the PLC's CPU and the industrial equipment it controls. Input modules receive signals from input devices like sensors, switches, and buttons, converting them into a format the CPU can understand. These signals can be simple on/off states or variable analog inputs like temperature or pressure readings.

Conversely, output modules take the digital commands from the CPU and convert them into electrical signals that can control output devices. These devices might include motors, lights, solenoids, or valves. The I/O modules are what allow the PLC to interact with and control the physical world.

Memory and Storage Functions

Memory and storage functions are critical to a PLC’s operation, as they hold both the operating system and the user-defined control program. PLC memory is typically divided into two main types: RAM (Random Access Memory) and ROM (Read-Only Memory). ROM stores the PLC's operating system, while RAM is used for the user program and data storage during execution.

The user program, created with plc programming software, is loaded into the PLC's memory. This program contains the specific logic—the set of rules and instructions—that the CPU will execute to control the machinery. The amount of available memory determines the complexity and size of the control program a PLC can handle.

These storage functions are also vital for data acquisition. As the PLC runs, it can log operational data, error codes, and production metrics. This information can be stored in memory and later retrieved for analysis, troubleshooting, or performance monitoring, making memory a key resource for both control and diagnostics.

Main Types of PLCs

Not all automation tasks are the same, which is why programmable logic controllers come in various forms to meet different needs. Choosing the right type of PLC is a critical step in designing an efficient and cost-effective control system. The main categories are generally based on their construction and scalability.

The most common distinctions are between a fixed PLC and a modular PLC, as well as a compact PLC versus a rack-mounted PLC. Each type offers a unique combination of features, I/O capacity, and expandability, making them suitable for different scales of industrial automation. Understanding these differences will help you select the best fit for your project.

Fixed and Modular PLCs

The primary difference between a fixed PLC and a modular PLC lies in their architecture and scalability. A fixed PLC, often called a brick or compact PLC, integrates the processor, power supply, and a set number of input and output points into a single unit. This design makes them simple, cost-effective, and ideal for smaller, standalone applications.

In contrast, a modular PLC is composed of separate components or modules that are plugged into a common rack or bus. This allows you to customize the system by selecting specific modules for the CPU, power supply, I/O, and communications. This design is highly scalable, making it the primary automation method for large or complex systems that may need to expand over time. You can easily add more I/O or advanced function modules as your needs evolve, even in remote locations.

Here is a quick comparison:

- Fixed PLC: All-in-one unit with a set I/O count, best for small-scale projects.

- Modular PLC: Customizable with separate modules, offering high scalability for complex systems.

Rack-mounted vs. Compact PLCs

Building on the fixed versus modular concept, PLCs can also be categorized by their physical form factor: compact or rack-mounted. A compact PLC is typically an all-in-one unit with a small footprint, making it perfect for applications where space is limited. These are often fixed I/O controllers but can sometimes be expanded with a limited number of additional modules.

A rack-mounted PLC is a type of modular PLC where all components, including the CPU, power supply, and I/O modules, are installed onto a standardized rack or chassis. This configuration allows for a high degree of customization and supports a large number of I/O points, making it suitable for large-scale, complex automation. The physical connection between modules is handled by the backplane of the rack.

Choosing between them depends entirely on your application requirements. Modern PLCs offer options in both categories, so matching the controller to the job is key.

| Feature | Compact PLC | Rack-mounted PLC |

|---|---|---|

| Form Factor | Small, all-in-one unit | Larger, modular components on a rack |

| I/O Capacity | Limited, often fixed | High, easily expandable |

| Scalability | Low to moderate | High, easily expandable |

| Best For | Small machines, standalone tasks | Large processes, entire plant control |

Programming Languages for PLCs

A programmable logic controller would be nothing without the instructions that tell it what to do. The process of creating these instructions is known as plc programming. Unlike general-purpose computer programming, PLC programming uses a set of standardized languages defined by the IEC 61131-3 standard, which are designed to be intuitive for automation professionals.

These programming languages provide different ways to express control logic. The most common languages include Ladder Logic (LL), Function Block Diagrams (FBD), and Structured Text (ST). Each has its own strengths and is suited for different types of tasks, from simple digital logic to complex mathematical algorithms.

Ladder Logic

Ladder Logic, also known as a ladder diagram, is the most widely used language for plc programming. Its graphical format was designed to mimic the appearance of the hard-wired relay logic circuits that it replaced. This familiarity made it easy for electricians and technicians to transition to programming PLCs without needing a background in computer science.

The language is structured with two vertical rails representing power and horizontal rungs that contain the control logic. Logic on the rungs consists of contacts (inputs like switches or sensors) and coils (outputs like motors or lights). When a path of true contacts exists on a rung, the output coil is energized.

This visual and straightforward approach makes Ladder Logic exceptionally well-suited for discrete control tasks common in industrial applications. The programming software for PLCs provides a user-friendly interface for creating, editing, and troubleshooting ladder diagrams, securing its place as a cornerstone of industrial automation.

Function Block Diagram and Structured Text

While Ladder Logic is popular, other programming languages offer advantages for different types of control problems. Function Block Diagrams (FBD) are another graphical language. FBD represents logic using blocks that represent specific functions, such as timers, counters, or mathematical operations. These blocks are then connected with lines to show the flow of data and execution.

This block-based approach is highly intuitive for visualizing signal flow and is particularly useful in process control applications where a continuous flow of data is being managed. It simplifies the representation of complex operations by encapsulating them within standardized blocks.

For tasks requiring complex algorithms or mathematical calculations, Structured Text (ST) is often the preferred choice. ST is a high-level, text-based language with a syntax similar to Pascal or C. It allows programmers to use loops, conditional statements, and complex equations, making it ideal for advanced process control, data manipulation, and motion control applications that are difficult to implement graphically.

PLC Programming Process

Creating a functional control system involves more than just writing code. The PLC programming process is a structured workflow that ensures the final program is reliable, efficient, and safe. This process typically involves using a suite of specialized development tools and following a series of logical steps from concept to implementation.

Modern plc programming software provides not only an editor for writing code but also powerful simulation tools to test the logic before it is deployed on live equipment. This helps catch errors early and reduces the risk of costly downtime or equipment damage.

Development and Simulation Tools

The primary tool for any PLC programmer is the programming software provided by the PLC manufacturer. These integrated development environments (IDEs) are comprehensive software packages that contain everything needed to create, download, and monitor a PLC program. They include editors for writing code in various languages, such as Ladder Logic or Structured Text.

A key feature of modern development tools is the inclusion of simulation tools. A simulator allows you to run and test your PLC program on your computer without being connected to a physical PLC. This virtual environment mimics the behavior of the PLC and its connected I/O, letting you verify your logic in a safe and controlled setting.

You can use these tools to test how the program responds to different inputs and conditions, helping to debug the code before it ever controls real machinery. This capability is invaluable for validating complex logic, testing data acquisition routines, and training new programmers.

Typical Steps in Writing PLC Programs

While every project is unique, the process of writing PLC programs generally follows a set of established steps. This systematic approach ensures that all requirements are met and that the resulting program is robust and easy to maintain. Using the provided programming software, a developer can move from an idea to a functioning control system.

Whether you are automating a simple conveyor or handling complex tasks like robotic control, adhering to a structured process is key. The complexity of the task will influence the detail required at each stage, but the overall workflow remains consistent.

The typical steps involved are:

- Define the Requirements: Clearly outline what the machine or process needs to do. Identify all inputs, outputs, and the sequence of operations.

- Plan the Program Logic: Design the control logic flow. This can be done using flowcharts or pseudo-code before writing the actual program in a language like Ladder Logic.

- Write and Document the Code: Use the PLC programming software to write the code. Add comments and descriptions to make the program understandable for future troubleshooting.

- Simulate, Test, and Deploy: Thoroughly test the program using simulation tools. Once verified, download the program to the PLC and perform final testing on the actual equipment.

Key Features of PLCs for Automation

The widespread adoption of PLCs in automation is due to a set of key features that make them uniquely suited for industrial control. A plc system is more than just a computer; it is a purpose-built solution designed for reliability and performance in demanding environments. These features are what set them apart from other control technologies.

Among the most important characteristics are flexibility, scalability, and real-time control capabilities. These attributes allow PLCs to adapt to changing production needs, grow with an operation, and execute commands with the timing precision required for safe and efficient motion control and management of output signals.

Flexibility and Scalability

Flexibility is a cornerstone of PLC technology. Unlike old hard-wired relay panels, PLCs can be reprogrammed easily to accommodate changes in industrial processes. If a production line needs to be modified or a new product is introduced, the control logic can be updated through software without requiring extensive and costly rewiring.

This flexibility is complemented by scalability, especially in modern PLCs. Modular designs allow a control system to grow as a business expands. You can start with a basic setup and add more I/O modules, communication ports, or advanced function modules as needed. This ensures that the initial investment remains valuable over the long term.

These features are critical for adapting to evolving manufacturing demands:

- Flexibility: Easily reprogrammed to alter or improve process control.

- Scalability: Systems can be expanded by adding modules to handle more inputs and outputs.

- Future-Proofing: Allows for upgrades to more powerful CPUs or new technologies without replacing the entire system.

Real-time Control Capabilities

One of the most critical features of a PLC is its ability to operate in real time. This means it can execute its program and respond to input changes within a very short and predictable timeframe, typically measured in milliseconds. This rapid response is essential for the precise control of machinery.

The PLC achieves this through its cyclical operating principle, known as the scan cycle. In each cycle, the PLC reads inputs, executes the program logic, and updates the output signals. The time it takes to complete one cycle is consistent, which guarantees that control actions happen exactly when they are needed.

This deterministic behavior is crucial for applications requiring high-speed and time-sensitive operations, such as packaging, robotics, and motion control. The PLC's real-time performance ensures that processes are synchronized, products meet quality standards, and the overall control of machinery is both safe and efficient.

Advantages of PLC-Based Automation

Beyond their core features, using PLCs for automation offers a host of practical advantages that have made them the industry standard. Their design and functionality translate directly into tangible benefits for the factory floor, including enhanced reliability and simplified maintenance. These benefits are why PLCs are trusted in countless industrial applications.

Furthermore, their ability to integrate seamlessly with other industrial systems is a major advantage. Using standard communication protocols, PLCs can connect to everything from operator panels to plant-wide management software, creating a truly connected and intelligent automation environment.

Reliability and Ease of Maintenance

PLCs are engineered for exceptional reliability. They are solid-state devices with no moving parts, designed to operate continuously in harsh industrial environments. They can withstand wide temperature ranges, high humidity, vibration, and significant electrical noise, conditions that would quickly cause a standard computer to fail.

This robust design translates to high uptime and reduced production losses. When issues do arise, the modular nature of many PLC systems makes maintenance straightforward. Onboard diagnostics help pinpoint faults quickly, and individual modules can be easily swapped out, often without shutting down the entire system. This simplifies troubleshooting and minimizes downtime.

Key factors contributing to reliability and ease of maintenance include:

- Rugged Construction: Built to tolerate industrial conditions.

- Modular Design: Allows for quick replacement of faulty components.

- Built-in Diagnostics: Helps technicians identify and resolve issues faster.

Integration with Other Industrial Systems

A significant advantage of modern PLCs is their ability to communicate and integrate with a wide array of other industrial devices and systems. They are not isolated controllers but rather key components in a larger automation ecosystem. This integration is achieved through support for various standard communication protocols like EtherNet/IP, Modbus, and PROFINET.

This connectivity allows PLCs to share data with a Human Machine Interface (HMI), which provides operators with a graphical display for monitoring and controlling the process. An HMI can show real-time data, display alarms, and allow operators to change setpoints or manually control equipment, all through a user-friendly touchscreen.

At a higher level, PLCs can be connected to Supervisory Control and Data Acquisition (SCADA) systems. This enables centralized monitoring and control of an entire plant or multiple facilities from a single control room. This level of integration is essential for large-scale operations, like those pioneered by companies such as General Motors, to optimize production and make data-driven decisions.

Conclusion

In conclusion, understanding Automation PLCs is essential for anyone involved in industrial automation. They offer a range of features that enhance flexibility, scalability, and real-time control capabilities, making them indispensable in modern manufacturing processes. By integrating PLCs into your systems, you can achieve a level of reliability and ease of maintenance that optimizes productivity and efficiency. As automation continues to evolve, staying informed about the latest advancements in PLC technology will empower you to make informed decisions for your operations. If you're ready to explore how PLCs can transform your automation strategies, don't hesitate to get in touch for a consultation.

Study PLCs/Automation More or Get Out While I Still Can?

Studying PLCs and automation can significantly enhance your career prospects, as these technologies are increasingly vital in various industries. Embracing this knowledge now will prepare you for future opportunities, making it a valuable investment. However, it’s essential to assess your interest and industry trends before committing fully.