The Role of Automation PLC in Modern Industries

Key Highlights

- A programmable logic controller (PLC) is a rugged industrial computer central to modern industrial automation.

- PLCs operate in real time, reading inputs from sensors and controlling outputs like motors and valves.

- PLC programming uses languages like Ladder Logic and Function Block Diagrams to define control sequences.

- Various communication protocols enable PLCs to connect with other devices, including HMIs and SCADA systems.

- PLCs are essential across diverse industrial applications, from manufacturing assembly lines to complex process control.

Introduction

In the world of industrial automation, efficiency, reliability, and precision are paramount. At the heart of most automated systems lies a powerful device: the programmable logic controller (PLC). These specialized computers have become the primary method for controlling machinery and processes across countless industrial applications. From simple machine functions to entire production lines, the PLC provides the flexible and robust control that modern industries depend on. Understanding their role is key to appreciating the backbone of today's automated landscape.

Understanding PLCs in Industrial Automation

The programmable logic controller has solidified its place as the primary automation method for a reason. It offers easily modifiable control for a vast range of industrial processes, operating in real time to ensure immediate responses to changing conditions. This ability to function reliably in demanding environments makes it indispensable.

The main difference between a PLC and other computing systems is its rugged design and its focus on control tasks. How exactly does this device function within a broader automation system? Let's explore what a PLC is and how its operational cycle works.

What Is a Programmable Logic Controller (PLC)?

A programmable logic controller is an industrial computer specifically designed for the control of machinery and manufacturing processes. Invented in the late 1960s to replace hard-wired relay systems, PLCs provided a more flexible and easily programmable solution for automation. The first PLC, the Modicon 084, was developed for General Motors.

The main difference from a standard computer is its robust construction. PLCs are built to withstand harsh industrial environments, offering resistance to electrical noise, extreme temperatures, vibration, and impact. This durability ensures reliable performance on the factory floor.

Ultimately, a PLC is the "brain" of an automated system. It receives information from sensors and input devices, processes it according to a user-written program, and sends commands to output devices, thereby managing the entire operation.

How PLCs Operate Within Automation Systems

PLCs operate in a continuous loop known as a scan cycle, which allows them to manage process control and other control systems effectively. This cycle consists of three primary steps. First, the PLC scans the status of all connected input devices, such as sensors, buttons, and switches, to gather current data from the machine or process.

Next, the PLC executes the user-created program. This logic determines what actions to take based on the input data it just received. The program's instructions dictate how the output signals should be adjusted to achieve the desired outcome.

Finally, the PLC updates the status of the output devices based on the program's logic. This involves sending signals to control various components. Common actions include:

- Turning motors on or off

- Opening or closing valves

- Adjusting the speed of a conveyor belt

After updating the outputs, the PLC performs internal diagnostics and then immediately restarts the scan cycle.

Key Components and Architecture of PLC Systems

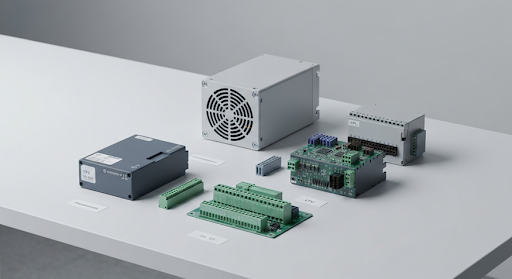

A typical PLC system is not a single entity but a collection of components working together. The architecture is designed for modularity and reliability in an industrial setting. The core of any PLC is its central processing unit, which acts as the brain of the operation.

To interact with the physical world, the PLC system relies on modules for input devices and output devices. These components, along with a stable power supply, form the basic structure of the controller. Let's look at each of these key parts in more detail.

Central Processing Unit (CPU) Structure

The Central Processing Unit (CPU) is the heart of the programmable logic controller. As the main processing unit, it is responsible for executing the user-written control program, performing logical operations, and managing communications with other devices. It's what makes the PLC a specialized industrial computer.

The main difference between a PLC's CPU and that of a general-purpose computer lies in its focus on real-time processing. The CPU constantly runs a scan cycle to read inputs, execute logic, and update outputs with minimal delay, which is critical for controlling industrial machinery safely and efficiently.

This processing unit also contains memory for storing the operating system, the user program, and data from the process. Its powerful design allows it to handle complex instructions and perform mathematical calculations, making it capable of managing sophisticated automation tasks.

Input/Output Modules and Their Functions

Input/Output (I/O) modules are the bridge between the PLC's CPU and the industrial equipment it controls. They provide the physical connection to various input devices and output devices. Input modules convert signals from sensors, switches, and buttons into data that the CPU can understand.

Output modules do the opposite. They take the digital instructions from the CPU and convert them into signals that can control devices like motors, lights, and valves. I/O modules can handle both digital (on/off) signals and analog signals, such as those from temperature or pressure sensors that provide a range of values. This versatility allows for precise control over many different processes, even those with components in remote locations.

The table below shows examples of common input and output devices.

| Input Devices (Provide data to the PLC) | Output Devices (Receive commands from the PLC) |

|---|---|

| Pushbuttons and Switches | Motors and Drives |

| Proximity and Photoelectric Sensors | Valves and Solenoids |

| Temperature and Pressure Transmitters | Indicator Lights and Alarms |

| Encoders and Level Sensors | Heaters and Relays |

Power Supply and Safety Features

A stable and reliable power supply is a critical component of any PLC system. It converts the available AC voltage into the various DC voltage levels required by the CPU and I/O modules to function correctly. Without a clean power source, the entire control system could fail.

PLCs are engineered with numerous safety features to ensure they can operate continuously in harsh industrial environments. This rugged design is a key differentiator from standard computers. These features include:

- Immunity to electrical noise from motors and other equipment.

- Resistance to physical vibration and impact.

- The ability to operate across extended temperature ranges.

For critical applications where failure could lead to harm, a specialized safety PLC is used. These devices have redundant processors and additional diagnostics to ensure the system fails in a predictable and safe manner, protecting both personnel and machinery.

Types of PLCs Used in Modern Industries

Not all industrial applications are the same, and modern PLCs come in various forms to meet different needs. The types of PLC available range from small, compact units for simple tasks to large, modular systems for controlling entire factories. This variety ensures that you can find a controller that fits your specific requirements and budget.

Choosing the right PLC depends on factors like the number of I/O points, processing power, and the complexity of your automation task, whether it's for simple assembly lines or advanced process control. Understanding the main categories can help you make an informed decision.

Fixed PLCs vs. Modular PLCs

The main difference between a fixed PLC and a modular PLC lies in their architecture and scalability. A fixed PLC, often called a brick PLC, is a self-contained unit with the processor, power supply, and a set number of input and output points all in one housing.

These controllers are ideal for smaller applications with straightforward control needs, like simple assembly lines or standalone machines. Their benefits include:

- Lower initial cost

- Compact size

- Simplicity of setup

In contrast, a modular PLC is composed of separate components (CPU, power supply, I/O modules) that are mounted on a rack or base. This design offers great flexibility, allowing you to customize and expand the system by adding more modules as needed. Modular PLCs are better suited for large-scale or complex process control applications where scalability and customization are critical.

Micro, Small, and Large PLCs: Choosing the Right Fit

Beyond the fixed versus modular distinction, PLCs are also categorized by size and capability: micro, small, and large. Your application requirements will determine which size is the most appropriate fit for your control systems.

A micro PLC is the smallest and most affordable option, perfect for replacing a few relays or timers in a simple machine. A small PLC offers more I/O and processing power, making it suitable for applications that are slightly more complex but still contained. Large PLCs are the most powerful, designed for controlling entire plants or complex, high-speed machinery.

When choosing the right fit, consider the following:

- Micro PLC: Best for standalone tasks and beginner projects.

- Small PLC: Good for machine control and small-scale process automation.

- Large PLC: Necessary for extensive I/O counts, advanced data handling, and plant-wide control.

Main Functions of PLCs in Automation

The primary purpose of a PLC is automation, but this breaks down into several key functions that make them more advantageous than traditional relay systems. PLCs excel at sequential control, but their capabilities extend far beyond that. They are also used for advanced tasks like motion control, data acquisition, and process monitoring.

These functions allow for precise, repeatable, and efficient management of industrial processes. From providing supervisory control over a system to logging critical operational data, PLCs are versatile tools. Let’s examine these functions more closely.

Control, Monitoring, and Data Acquisition

At its core, a PLC is built for control. Using programming software, engineers design logic that tells the control systems how to operate based on real-time feedback. This enables precise and automated management of machinery and processes, a significant advantage over manual or mechanical systems.

Beyond just control, PLCs are essential for monitoring and supervisory control. They constantly watch the status of a system, providing operators with vital information and alerting them to any issues. This allows for quick troubleshooting and reduces downtime. Many PLCs have built-in features for this, such as OLED displays on modules.

An equally important function is data acquisition. PLCs can log vast amounts of operational data, which is invaluable for process optimization and quality control. Key functions include:

- Logging production counts and cycle times.

- Recording temperature, pressure, and flow data.

- Tracking alarm history and fault conditions.

Motion Control and Sequencing

A specialized yet critical function of many modern PLCs is motion control. This involves the precise control of the position, speed, and torque of electric motors, such as servos and steppers. For applications like robotics, CNC machines, and high-speed packaging, this level of accuracy is essential.

PLCs execute motion control commands in real time, ensuring that movements are perfectly synchronized and repeatable. This capability allows manufacturers to automate complex tasks that require a high degree of precision, something that would be impossible with simpler control methods.

In addition to motion, PLCs excel at sequencing. They can manage a series of operations in a specific order, with each step triggered by the completion of the previous one or by a timed delay. This foundational ability to control sequences is what makes PLCs so effective at automating entire assembly lines and manufacturing processes.

PLC Programming Languages and Methods

To perform its functions, a PLC needs a set of instructions. This is where PLC programming comes in. Unlike general-purpose computers, PLCs use specialized programming languages designed for industrial control tasks. There are several standard programming methods, each with its own strengths.

The most common language is Ladder Logic, which is graphical and easy for technicians to understand. However, other languages like Function Block Diagrams and Structured Text are also widely used, especially for more complex processes. Let's look at these different programming languages.

Ladder Logic and Its Industrial Application

Ladder Logic, also known as a Ladder Diagram (LD), is the most widely used of all PLC programming languages. Its popularity stems from its graphical format, which resembles the electrical relay circuits it was designed to replace. This makes it intuitive for electricians and technicians who are already familiar with electrical schematics.

In a Ladder Logic program, power flows along vertical "rails," and logic is implemented on horizontal "rungs." The core components of this PLC programming language are:

- Contacts: Represent inputs like switches and sensors (Normally Open or Normally Closed).

- Coils: Represent outputs like motors or lights.

This straightforward structure makes it an excellent choice for a wide range of industrial applications, particularly those involving discrete control, such as managing conveyor systems or assembly lines. Its visual nature also simplifies troubleshooting on the factory floor.

Function Block Diagram, Structured Text, and Others

While Ladder Logic is popular, other PLC programming languages offer advantages for different types of tasks. Function Block Diagrams (FBD) are another graphical language. FBDs represent functions, such as timers or counters, as blocks connected by lines, which is useful for visualizing signal flow in process control.

Structured Text (ST) is a high-level, text-based language similar to Pascal or C. It is ideal for implementing complex tasks that involve mathematical calculations, loops, and conditional logic. This makes it a powerful choice for advanced algorithms that would be cumbersome to write in a graphical language.

According to the IEC 61131-3 standard, there are five recognized languages, giving programmers flexibility. Besides the ones mentioned, these include:

- Sequential Function Chart (SFC): Organizes the program into steps and transitions, perfect for sequential processes.

- Instruction List (IL): A low-level, assembler-like language.

How PLC Programming Is Carried Out

The process of PLC programming involves more than just writing code. It is a structured workflow that begins with defining the control requirements and ends with deploying a fully tested program. This process is typically done using dedicated programming software provided by the PLC manufacturer.

This software allows you to choose your preferred programming methods, write the logic, and then transfer it to the PLC. Before going live, crucial steps like simulation and testing are performed to ensure the program works as intended and is free of errors that could cause downtime or safety issues.

Steps in Developing a PLC Program

Developing a PLC program follows a logical sequence to ensure a successful outcome. The journey from concept to a functioning control system begins with a clear understanding of the goals. The first step in PLC programming is to define the machine or process control requirements in detail.

Once the requirements are clear, the developer can begin designing the logic. This involves selecting the appropriate input devices and output devices and mapping them within the programming software. The programmer then writes the control logic using a language like Ladder Logic to dictate how the outputs should respond to different input conditions.

The typical development process includes these key steps:

- Defining the operational sequence and safety interlocks.

- Writing the code in the chosen programming language.

- Assigning memory addresses and creating documentation within the program.

- Saving and compiling the program to check for syntax errors.

Simulation, Testing, and Troubleshooting

After writing the PLC programming, the next critical phase is verification. Simulation allows you to test your logic in a virtual environment using the programming software without needing the physical hardware. This helps catch logical errors early, saving time and preventing potential damage to equipment.

Once simulation is complete, the program is downloaded to the PLC for live testing. This phase involves checking that all inputs are read correctly and that the output signals behave as expected under real-world conditions. Troubleshooting is a common part of this stage. An issue might not be in the code but in the physical wiring or a faulty sensor.

Common challenges that arise during implementation include:

- Incorrect wiring of I/O modules.

- Communication errors between the PLC and other devices.

- Logical flaws in the program that only appear under specific conditions.

PLCs in Real-World Industrial Applications

The true value of PLCs is evident in their vast range of real-world industrial applications. They are the workhorses behind the scenes in nearly every sector you can imagine. In manufacturing, they orchestrate complex assembly lines, ensuring every step happens in perfect sequence.

In process automation, such as in chemical plants or water treatment facilities, they monitor and regulate variables like temperature and flow to maintain quality and safety. They control all manner of output devices to make modern industry possible. Let's explore some specific examples.

Examples From Manufacturing, Process Automation, and Home Automation

In manufacturing, PLCs are everywhere. The automotive industry, where General Motors first commissioned the PLC, uses them extensively for robotic welding, painting, and assembly lines. Operators often interact with these systems through a Human Machine Interface (HMI) that displays system status and allows for control.

For process automation, PLCs are crucial in industries like food and beverage for tasks like batch mixing, cooking, and packaging. In water treatment plants, they control pumps, valves, and chemical dosing to ensure water quality. They provide the reliable, 24/7 control these critical processes demand.

While less common, PLCs can also be used in home automation for advanced control of lighting, HVAC, and security systems. Some examples include:

- Manufacturing: Conveyor belt control, packaging and labeling machines.

- Process Automation: Oil and gas refineries, pharmaceutical production.

- Home Automation: Sophisticated lighting scenes, automated irrigation systems.

Conclusion

In conclusion, Programmable Logic Controllers (PLCs) play a vital role in modern industrial automation, streamlining processes and enhancing efficiency. By understanding their structure, functionality, and programming methods, industries can leverage PLCs to achieve greater control and monitoring capabilities. From manufacturing to process automation, the versatility of PLCs is evident in various applications, making them an indispensable part of contemporary industries. As technology continues to evolve, staying informed about PLC advancements will be essential for businesses looking to maintain a competitive edge. If you're ready to explore how automation can transform your operations, get in touch with us today for a consultation.

Frequently Asked Questions

How do PLCs communicate with other automation devices?

PLCs use various communication protocols like EtherNet/IP, Modbus, and PROFINET to talk to other devices. This physical connection allows the industrial computer to integrate seamlessly into larger control systems, exchanging data with HMIs, drives, and other PLCs to coordinate output signals.

What are the advantages of PLCs over traditional control systems?

The main difference is flexibility; PLCs are easily reprogrammed, unlike hard-wired relays. They offer higher reliability, advanced diagnostics, and can handle complex process control in real time. For critical tasks, a safety PLC provides an even higher level of dependability for industrial automation.

What are the latest innovations in PLC technology?

Modern PLCs feature better integration with IIoT platforms, enhanced cybersecurity, and more powerful processors. Innovations include improved programming software, edge computing capabilities to handle industrial processes locally, and easier control of equipment in remote locations, with an increasing focus on integrated safety PLC functions.