The Role of Automation PLC in Modern Industrial Systems

Key Highlights

- A Programmable Logic Controller (PLC) is a rugged industrial computer that automates and controls electromechanical processes.

- PLCs operate on a continuous scan cycle: reading inputs, executing programmed logic, and updating outputs to control machinery.

- The primary types of PLCs are fixed (compact) for simple tasks and modular for scalable, complex systems.

- PLCs offer significant advantages over traditional relays, including greater flexibility, reliability, and cost-efficiency.

- They are programmed using languages like Ladder Logic and integrate seamlessly with HMI and SCADA systems for comprehensive control.

- Modern PLCs are built to withstand harsh industrial environments, handling extreme temperatures and electrical noise.

Introduction

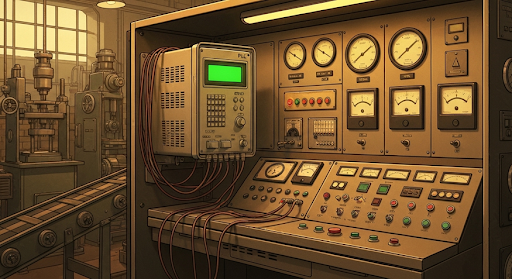

In the world of modern industrial automation, efficiency, reliability, and precision are paramount. At the heart of these advanced manufacturing and process environments is the Programmable Logic Controller (PLC). This specialized industrial computer acts as the brain for countless automated tasks, replacing outdated and inflexible hard-wired relay systems. By executing user-created programs, PLCs provide robust and adaptable management for a wide array of control systems, making them an indispensable tool in today's industries. Recent trends and innovations in PLC technology include the integration of Industrial Internet of Things (IIoT) connectivity, enhanced cybersecurity features, and support for cloud-based monitoring. Modern PLCs often feature higher processing speeds, improved data handling capabilities, and compatibility with advanced networking protocols, enabling more flexible, remote, and real-time automation solutions. These advancements are helping industries maximize efficiency and adapt to ever-changing operational demands.

Understanding Programmable Logic Controllers (PLCs) in Industrial Automation

The Programmable Logic Controller has become the primary automation method for countless industries, offering a level of control and modifiability that was previously unimaginable. These devices are the workhorses of industrial automation, designed specifically to operate reliably in harsh factory environments.

At their core, PLCs use programmable logic to execute a series of instructions. This allows you to change how a machine or process operates by simply altering a program, rather than performing a complex and costly rewiring of physical control systems. This flexibility is what makes the PLC a cornerstone of modern production. The following sections will explore what these devices are and the key roles they play.

Definition and Historical Development of PLCs

A Programmable Logic Controller, or PLC, is an industrial-grade digital computer used to automate specific processes or machines. It works by continuously monitoring inputs from devices like sensors and switches, processing this information through its programmed logic, and then controlling outputs like motors and valves. This cyclical process allows it to manage complex industrial control systems in real time.

The concept of the PLC emerged in the late 1960s out of a need for a more flexible alternative to hard-wired relay panels. The automotive industry, particularly General Motors, sought a solution that could be easily reprogrammed to accommodate changes in its assembly lines without extensive and time-consuming rewiring. The result was the invention of the first PLC, which revolutionized industrial control.

What started as large and expensive controllers has evolved dramatically. Today’s PLCs are compact, powerful, and cost-effective devices. Each contains a central processing unit (CPU), memory, and input/output sections, forming a complete system designed for the rigors of the factory floor.

Key Roles of PLCs in Automated Systems

The primary function of a PLC is the automated control of machinery and industrial processes. You can find them managing everything from simple machine functions to entire factory assembly lines. Their ability to handle complex logic makes them ideal for orchestrating sequences of operations with high precision and repeatability.

PLCs perform their duties by executing programmable logic created by a user. This logic dictates how the controller should react to various input conditions. For example, when a sensor detects a product is in position, the PLC processes this input and sends output signals to start a packaging sequence or move a robotic arm. This constant monitoring and response cycle is the essence of its function.

Compared to other control systems, PLCs offer enhanced capabilities for managing multiple inputs and outputs simultaneously. They excel at precise timing operations, data logging, and communication, enabling organizations to implement more sophisticated and efficient automation strategies. These functions provide a clear advantage over older, less flexible control methods.

Core Components and Architecture of a PLC System

Understanding the architecture of a PLC system is key to appreciating how it works. A typical PLC is composed of several core components working in unison. The central processing unit (CPU) acts as the brain, executing the control program and making decisions based on the logic you provide.

This CPU interacts with the outside world through input and output modules. Input devices, such as sensors and switches, provide real-world data to the PLC, including digital signals and analog inputs like temperature readings. The PLC then processes this data and sends commands to output devices like motors and lights, completing the control loop. Now, let’s look closer at these essential components.

Central Processing Unit (CPU) and Power Supply

The central processing unit (CPU) is the core of any PLC. It functions as the brain, responsible for executing the user-created control program stored in its memory. This rugged industrial computer performs all the necessary data processing, logical operations, and decision-making required to manage an automated system. Its ability to operate in real time ensures that control actions happen with minimal delay.

To function correctly, the entire PLC system relies on a stable power supply. This component converts the available plant power (e.g., 220V AC) into the various DC voltage levels required by the CPU and the input/output modules. A reliable power supply is crucial for ensuring the PLC operates without interruption, protecting against fluctuations that could disrupt production.

Together, the processing unit, memory, and power supply form the foundational hardware of the PLC. The CPU continuously runs a diagnostic check as part of its operating cycle, ensuring that all internal components are functioning correctly and maintaining the system's overall reliability.

Input/Output Modules and Signal Processing

Input/Output (I/O) modules serve as the interface between the PLC’s CPU and the industrial equipment it controls, creating the physical connection to the machinery. Input devices, such as sensors, pushbuttons, and switches, are wired to input modules. These modules read the status of these devices and convert the signals into data that the CPU can understand.

Conversely, output devices like electric motors, solenoid valves, and indicator lights are connected to output modules. After the CPU executes its logic, it sends command signals to these modules, which then activate or deactivate the connected devices. This is how the PLC translates its logical decisions into physical actions on the factory floor.

The I/O system handles both digital (on/off) and analog signals. For example, analog inputs can come from sensors measuring pressure or temperature, providing a range of values rather than a simple on or off state. The PLC performs the necessary signal processing to interpret these varied inputs and generate the appropriate output commands, completing the control loop.

Main Types of PLCs and Their Applications

PLCs come in various forms to suit different needs, but they generally fall into two main categories: fixed PLC and modular PLC. A fixed, or compact, PLC is an all-in-one unit with a set number of inputs and outputs, making it ideal for smaller, well-defined industrial applications.

In contrast, a modular PLC is highly customizable, allowing you to add or remove I/O modules, communication adapters, and even upgrade the processor. This scalability makes it perfect for complex process control or applications that may grow over time. Additionally, specialized controllers like a safety PLC exist for critical functions. Let's examine these types in more detail.

Fixed (Compact) vs. Modular PLCs

A fixed PLC, often called a compact or brick PLC, integrates the processor, power supply, and a specific number of I/O points into a single, compact housing. These controllers are affordable and easy to install, making them an excellent choice for smaller industrial applications or standalone machines where the control requirements are straightforward and unlikely to change.

On the other hand, a modular PLC is designed for flexibility and scalability. Its architecture consists of separate components—CPU, power supply, and various I/O modules—that are mounted on a rack or base. This allows you to customize the PLC for your exact needs, whether for large-scale process control or systems that require future expansion. You can easily add more I/O or advanced function modules as your requirements evolve.

The main difference lies in this adaptability. Choosing the right type depends entirely on your project's scope. A fixed PLC is cost-effective for simple tasks, while a modular PLC provides the power and flexibility for complex, dynamic automation.

| Feature | Fixed (Compact) PLC | Modular PLC |

|---|---|---|

| Structure | All-in-one unit with integrated CPU, power, and I/O. | Separate, swappable modules for CPU, power, and I/O |

| Scability | Limited. I/O count is fixed. | Highly scalable. Add modules as needs grow. |

| Cost | Lower initial cost, more affordable for small projects. | Higher initial cost, but flexible for large systems. |

| Best For | Small applications, standalone machines, simple tasks. | Large-scale operations, complex process control, systems that may expand. |

Specialized PLC Types for Industrial Needs

Beyond the standard fixed and modular designs, many PLCs are engineered for specific industrial challenges. All industrial PLCs are built to be robust, capable of operating across wide temperature ranges and with a high immunity to electrical noise and physical vibration. This inherent durability makes them suitable for nearly any factory environment.

For more demanding tasks, specialized PLCs are available. For example, some controllers are designed specifically for high-precision motion control, offering built-in capabilities to manage servo or stepper motors with great accuracy. A safety PLC is another critical variant, designed with redundant processors and certified to handle emergency stop systems and other functions where failure is not an option.

Other specialized types address unique connectivity and integration needs. Models with built-in Wi-Fi or cellular communication are ideal for monitoring equipment in remote locations. Furthermore, controllers like the ProductivityOpen series provide an industrialized Arduino-compatible platform, blending the reliability of a PLC with the flexibility of open-source hardware for custom applications.

How PLCs Work: Operation and Scan Cycle

The operation of every PLC system is governed by a fundamental, repetitive process known as the scan cycle. This cycle is how the PLC interacts with its environment in real time, ensuring that it responds quickly to changes on the factory floor. It consists of three main steps that are executed sequentially and continuously.

First, the PLC performs data acquisition by reading the status of all its inputs. Next, it executes the user-defined program logic based on that data. Finally, it updates the status of its output signals to control the connected machinery. Let’s break down these steps to understand how this loop enables precise automation.

Input Sampling and Data Processing

The scan cycle begins with the data acquisition stage, also known as input sampling. During this first step, the PLC’s processing unit rapidly checks the status of every input device connected to it. This creates a snapshot of the current state of the system, capturing whether switches are on or off and pushbuttons are pressed.

This process includes reading both digital and analog signals. While digital inputs are simple on/off states, analog inputs provide a range of values, such as a temperature reading from a thermocouple or a pressure level from a transducer. The PLC reads these values and stores them in its memory to be used in the next stage of the cycle.

The ability to gather this diverse data accurately and in real time is a significant advantage of PLC-based systems. This comprehensive snapshot ensures that the control logic will be executed based on the most current information from the factory floor, leading to more responsive and reliable automation.

Execution of Control Logic and Output Actions

Once the input data is collected, the PLC moves to the second step of the scan cycle: executing the control logic. The CPU works through the user-created program—often written in ladder logic—instruction by instruction. It uses the input values it just saved to solve the logic and determine what actions, if any, need to be taken.

Based on the results of the program execution, the PLC proceeds to the third and final step: updating the outputs. The CPU sends command output signals to the output modules, which in turn energize or de-energize the connected devices. This is how the PLC's decisions are translated into physical actions that manage the control systems.

For instance, if the logic dictates that a motor on an assembly line should start, the PLC sends the appropriate signal to the motor controller. In a process control application, it might adjust a valve to regulate flow. This three-step cycle of reading inputs, executing logic, and writing outputs repeats continuously, allowing the PLC to seamlessly automate industrial processes.

Programming PLCs: Languages and Methods

The heart of a PLC's flexibility lies in PLC programming. This is how you instruct the controller on how to perform its tasks. While several standard programming languages are used, the most common is Ladder Logic, which is designed to be intuitive for those with a background in electrical relays.

Other graphical languages like Function Block Diagrams are also popular, along with text-based options for more complex tasks. This programming is typically done on a computer using specialized programming software and then downloaded to the PLC. The following sections will explore these languages and the tools used to implement them.

Ladder Logic, Function Block, and Structured Text

When it comes to PLC programming, you have several standard programming languages to choose from, each suited for different tasks and user preferences. While there are five internationally recognized languages (IEC 61131-3), a few are far more common in industrial practice. The choice often depends on the complexity of the control task and the experience of the programmer.

The most widely used languages differ in their approach, with some being graphical and others text-based. Understanding these differences can help you select the best one for your application.

- Ladder Logic (LD): The most popular language, LD is a graphical language that mimics the appearance of electrical relay schematics. Its visual nature makes it easy for technicians and engineers to understand and troubleshoot.

- Function Block Diagrams (FBD): This is another graphical language that uses blocks to represent functions like timers, counters, and mathematical operations. These blocks are connected by lines to show the flow of logic.

- Structured Text (ST): A high-level, text-based language similar to programming languages like Pascal. It is ideal for implementing complex mathematical calculations, loops, and conditional logic that would be cumbersome in a graphical language.

Programming Tools and Common Steps in Implementation

PLC programming is performed using dedicated programming software, which serves as the primary interface between you and the controller. These software packages, often called Integrated Development Environments (IDEs), provide all the necessary programming tools to write, edit, and troubleshoot your control logic. Examples include AutomationDirect's Productivity Suite or the widely used CODESYS development system.

The typical implementation process follows several key steps. First, you define the operational requirements of your machine or process. Next, you use the PLC programming software to write the control logic in your chosen language, such as Ladder Logic or Structured Text. Once the program is complete, you download it from your computer to the PLC's memory.

Modern programming software offers much more than just a text editor. These tools include powerful features for simulating and debugging your code, allowing you to test how it handles complex tasks before deploying it in a live industrial setting. This helps ensure a smoother and safer startup.

Communication and Integration with Other Devices

In modern automation, PLCs rarely work alone. They are part of a larger ecosystem that requires seamless data exchange with a variety of other devices. This integration is made possible through industrial communication protocols that allow PLCs to share information for monitoring and supervisory control.

Key components in this network include the Human Machine Interface (HMI), which provides a graphical display for operators, and SCADA systems, which offer plant-wide control and data acquisition. Understanding how PLCs communicate with these systems is essential for building a fully connected automation solution.

Industrial Networks and Protocols (Ethernet/IP, Modbus, etc.)

PLCs communicate with other automation devices using a variety of industrial networks and communication protocols. These established standards ensure that devices from different manufacturers can reliably exchange data. The communication typically occurs over a physical connection, with industrial Ethernet being one of the most common media used today.

Many protocols have become industry standards, each with its own strengths. Modern PLCs often support multiple protocols to provide maximum flexibility in system design. Some of the most prevalent include:

- Ethernet/IP: A leading industrial protocol that adapts the standard internet protocol for automation, enabling high-speed data exchange over standard Ethernet hardware.

- Modbus: One of the oldest and most widely adopted serial communication protocols, valued for its simplicity and reliability in connecting industrial electronic devices.

- EtherCAT: A high-performance, Ethernet-based fieldbus system known for its fast cycle times, making it ideal for motion control and other time-critical applications.

Many modern PLCs are equipped with multiple communication ports built directly into the CPU, such as Ethernet, serial, and USB. This allows them to connect simultaneously to HMIs, drives, and enterprise-level systems.

Data Exchange with Sensors, HMIs, and SCADA Systems

The PLC acts as a crucial hub for data exchange in an automated system. At the most fundamental level, it communicates with sensors and actuators on the plant floor, gathering status information and sending control commands. This raw data, however, is often needed by operators and managers for visualization and analysis.

This is where a Human Machine Interface (HMI) comes in. An HMI is a graphical display panel that connects directly to the PLC, providing operators with a user-friendly way to monitor processes, view alarms, and input commands. It translates the PLC's data into intuitive graphics, charts, and buttons.

For larger-scale supervisory control, PLCs integrate with SCADA systems (Supervisory Control and Data Acquisition). A SCADA system can communicate with multiple PLCs across an entire facility, collecting data for centralized monitoring, control, and historical reporting. This seamless flow of information from the PLC to HMI and SCADA systems is what enables comprehensive plant automation.

Advantages of Using PLCs Over Traditional Control Systems

The shift from traditional, hard-wired relay control systems to PLCs has brought transformative benefits to industrial automation. The primary advantages include vastly improved flexibility, scalability, and reliability. Unlike relay panels that required manual rewiring for any change, a PLC can be reprogrammed in minutes.

Furthermore, PLCs offer enhanced cost efficiency and simplified maintenance. Their solid-state design and built-in diagnostic tools reduce downtime and make troubleshooting faster and easier. Let's explore these benefits in more detail to understand why PLCs have become the industry standard.

Flexibility, Scalability, and Reliability

One of the greatest advantages of PLCs is their incredible flexibility. In the past, changing a control sequence meant a time-consuming and expensive process of manually rewiring relay panels. With a PLC, you can modify the entire operation by simply editing and downloading a new program. This allows you to adapt to changing production requirements quickly and efficiently.

Scalability is another key benefit, particularly with modular PLC systems. As your automation needs grow, you can easily expand the system by adding more input/output modules, communication adapters, or a more powerful CPU. This ensures that your initial investment can evolve with your business, unlike fixed relay systems that would need to be completely replaced.

Finally, modern PLCs deliver exceptional reliability. As a solid-state industrial computer, a PLC has no moving parts that can wear out, unlike mechanical relays. They are designed to withstand harsh industrial conditions, including vibration, extreme temperatures, and electrical noise, ensuring consistent performance and minimizing costly downtime.

Cost Efficiency and Ease of Maintenance

While the initial hardware cost may seem higher than simple relays, PLCs provide long-term cost efficiency. They significantly reduce the amount of wiring required, which lowers installation labor and material costs. More importantly, their ability to streamline industrial processes and reduce downtime leads to greater productivity and a better return on investment over time.

Ease of maintenance is another major advantage. PLCs come with built-in diagnostic and monitoring tools that allow technicians to quickly identify faults in the system. Instead of manually tracing wires through a complex panel, you can use programming software to pinpoint issues with I/O points or logic errors, drastically reducing troubleshooting time on assembly lines.

This benefit is amplified for systems in remote locations. Many PLCs can be accessed over a network, allowing engineers to diagnose and even reprogram them without being physically present. This remote capability further reduces maintenance costs and ensures that equipment stays operational with minimal interruption.

Conclusion

In conclusion, the integration of Programmable Logic Controllers (PLCs) into modern industrial systems marks a significant advancement in automation technology. With their ability to offer flexibility, scalability, and reliability, PLCs have become indispensable for managing complex automation tasks efficiently. Understanding the core components and operation of PLCs enables industries to enhance productivity and maintain a competitive edge. As you explore the various types of PLCs and their applications, it becomes evident that their role is pivotal in optimizing industrial processes. If you're looking to elevate your automation project, don’t hesitate to get in touch for a free consultation to discuss PLC solutions tailored to your needs.

Frequently Asked Questions

How do I select the best PLC for my automation project?

To select the best Programmable Logic Controller, first analyze your application requirements. For small, standalone tasks, a fixed PLC is cost-effective. For larger or expanding systems, choose a modular plc. For critical functions, consider a specialized safety plc.

What are some real-world examples of industrial PLC applications?

PLCs are used in numerous industrial applications. They control industrial processes like packaging and material handling, manage factory assembly lines, and automate precise motion control systems. They also provide supervision and control for water treatment plants and food processing equipment.

What are common troubleshooting issues when working with PLC-based automation?

Common troubleshooting issues for a plc system include faulty I/O modules, errors in the programming software logic, and communication failures. External factors like electrical noise from other equipment or malfunctioning input devices such as sensors are also frequent problems.