Beginner's Guide to Automation PLC: Basics Explained

Key Highlights

Here is a quick summary of what you will get from this guide:

- A programmable logic controller (PLC) is a tough computer made for the factory floor. It is used to control machines and make sure things run the right way.

- Programmable logic controllers are at the heart of modern industrial automation. They take the place of the older, fixed relay systems.

- You will find that these devices sit in the center of many control systems. They take signals from sensors and switches, then carry out commands.

- When it comes to plc programming, people often use ladder logic. This is a simple language that looks like an electrical diagram.

- If you want to do well in manufacturing, robotics, or process control, you need to understand programmable logic controllers.

These keywords like programmable logic, industrial automation, ladder logic, control systems, and plc programming matter for anyone interested in the field.

Introduction

Welcome to the world of industrial automation. In many places, you will find a device called a programmable logic controller, or PLC. This small computer runs the machines in factories, power plants, and other places where you see automation. The PLC is the main part that makes modern control systems work. It helps all kinds of complex operations go well, with no big problems. Programmable logic controllers are made to keep everything working on time and as it should. In this guide, you will get to know the basics of PLCs and see how important they are for industrial automation.

Understanding PLCs in Automation

programmable logic controller is not just any computer. It is built for the hard demands of industrial automation. These programmable controllers are made to handle tough conditions. They carry out exact instructions to run many things. You can use them in anything, from a simple assembly line to a complex chemical process. They are flexible and strong, so most modern industries rely on them.

In the center of many control systems, you will find a programmable logic controller at work. It gives the brains needed to automate jobs. Many of these jobs used to be done by hand or with systems that had less flexibility. Now, let’s look at what programmable logic controllers do and see how they fit into an automated system.

What Is a Programmable Logic Controller (PLC)?

A programmable logic controller is a strong type of industrial computer. It is made to help automate electrical and mechanical tasks. This controller is very different from the usual home computer. The main difference is that it works well in tough industrial environments. It can handle extreme temperatures, hard vibrations, and lots of electrical noise. It is built to last in these harsh industrial environments. It also has a real-time system made for control jobs.

Inside, a programmable memory holds the user’s program. The programmable logic controller repeats the same steps in a scan cycle. The first part is reading the status of all input devices, like sensors or buttons. After this, it runs the stored program and makes decisions using the inputs. The last part is changing the state of connected output devices, such as motors or lights.

The scan cycle happens very fast, in just a few milliseconds. That means the industrial computers can control things in real-time. When they read inputs and quickly control outputs, they make automation fast and exact. These features are why programmable logic controllers have become so important in many industrial environments.

The Role of PLCs in Modern Automation Systems

In today’s industrial automation, PLCs are at the center of process control and the control of machinery. Their main job is to follow a set of steps that were programmed ahead of time. They use these steps to help manage and check on equipment on the factory floor. This could be as easy as starting or stopping a conveyor belt. It could also include running the complex steps of a robotic assembly.

PLCs act as the link between the machines and higher-level systems like SCADA (Supervisory Control and Data Acquisition) or HMI (Human-Machine Interface). They take orders from a human operator or a bigger system and turn these into things that happen with the machinery on the floor. This hands-on control makes sure every part of an automated system works together.

PLCs handle all the logic and timing needed for the job. This lets industrial processes run better, makes product quality steady, and be safer. With PLCs, an automated system can work with almost no human giving orders the whole time. That is why PLCs are a key part of modern industrial automation and supervisory control.

Key Components of a PLC System

working PLC system has many important parts that work together. At the center is the processing unit, often called the CPU. This part is like the brain of the system. It runs the control program. The processing unit is connected to input devices that send in real-time data and output devices that follow commands.

The PLC system needs a steady power supply to work well. It also uses different communication protocols to talk with other computers, networks, and many types of interfaces. If you understand how these parts work together, it is easy to see how a PLC system handles even the most complex tasks in automation.

Central Processing Unit (CPU)

The Central Processing Unit (CPU) is at the heart of every PLC system. This microprocessor is the part that runs the user-made logic, handles calculations, and manages all of the other parts of the PLC system. It keeps checking on itself to make sure everything is running right, which makes it a strong and trusted piece for use in industrial environments.

The processing unit works in a basic and repeated way. It reads inputs, runs the program stored in its memory, and updates the outputs after that. This way of working, known as a scan-based execution, sets PLCs apart from event-driven computers like regular PCs. The speed and memory size of the CPU is what lets the PLC work on more or less complex jobs.

The PLC’s CPU is made to be tough. It works well even when there are vibrations, big changes in temperature, and electrical noise common in industrial environments. This robust design makes sure the PLC system keeps control without stopping, which is important for both safety and keeping things running well.

Input and Output (I/O) Modules

Input and Output (I/O) modules connect the PLC's CPU to the machines it needs to control. Input devices, like sensors, switches, and buttons, send signals to the PLC. These signals tell the PLC about what is happening in the process. The modules change the electrical signals from these input devices into data that the CPU can understand.

Output modules do the reverse. They take directions from the CPU and change them into signals that control output devices. These output devices include motors, valves, lights, and pumps. The connected output devices carry out the actions the process needs.

I/O modules can work with both digital and analog signals. Digital I/O handles simple things that are either on or off. Analog I/O looks at a full range of values, such as temperature or pressure. This lets the PLC work with analog signals and manage complex data. It helps the system control tasks that need careful and precise actions.

Power Supply and Communication Interfaces

A good power supply is key for a PLC to work. It takes the normal AC power from the wall and turns it into the lower DC power that the CPU and I/O parts need. This part has a robust design, just like the other parts of the PLC. It can deal with changes in power and work in many temperature ranges without stopping.

Communication interfaces let the PLC talk and share data with other systems. These use different communication protocols, like EtherNet/IP or Modbus, to make a physical connection to HMIs, computers, and other PLCs. This is important for checking processes, saving data, and adding the PLC into a bigger factory network.

When you put together a strong power supply with many communication options, you get a PLC that is dependable and good for connecting. It can work by itself or be part of a group control system, even when times get tough.

Types of PLCs and Their Applications

Not all programmable controllers are the same. There is a wide range of these controllers out there. Each one is made for a different type of job and fits different sizes of work. This family of controllers is mostly split into two types: fixed and modular. The type you go with depends on what the automation project needs.

You can find PLCs in many different industrial applications. They are used in both small machines that work by themselves and big factory floors where many things must work together. Knowing about the different types will help you see how they work in different places. This also shows how they help more people get better control and do a good job.

Fixed vs. Modular PLCs

A fixed PLC, also known as an integrated or compact PLC, has a set number of input and output points built into a single unit. These controllers are typically smaller, more affordable, and ideal for simple, standalone automation tasks where the requirements are not expected to change. However, their lack of expandability makes them less suitable for complex or growing systems.

In contrast, a modular PLC features a scalable design where components are separated into individual modules. This allows you to customize the system by adding more I/O, memory, or communication modules as needed. The easy integration of new modules makes modular PLCs perfect for large-scale or complex applications that may evolve over time. While more expensive upfront, their flexibility often provides better long-term value.

Choosing between a fixed and modular PLC depends entirely on your project's scope, budget, and future needs.

| Feature | Fixed PLC | Modular PLC |

|---|---|---|

| Structure | All-in-one unit with built-in I/O, CPU, and power supply. | Separate modules for CPU, power, I/O, and communications. |

| Scalability | Limited to the built-in number of I/O points. | Highly scalable; add modules to expand capabilities. |

| Application | Best for small-scale, standalone machines and simple processes. | Ideal for complex, large-scale systems and evolving operations. |

| Cost | Lower initial cost. | Higher initial cost but greater long-term flexibility. |

| Maintenance | If one part fails, the entire unit may need replacement. | Faulty modules can be individually replaced, reducing downtime. |

Common Industrial Applications for PLCs

PLCs play a big part in many industrial processes. You can find them in lots of different sectors. In manufacturing, they are there to control assembly lines, robotic arms, and packaging machines. These control systems help the work move quickly and right. Their strong and steady performance is what keeps machine performance and product quality the same every hour of the day.

The food processing industry uses PLCs more than most. They control batching, mixing, and cooking. This helps keep the temperature and timing spot-on for safety and a good product, every time. People also use them in water treatment plants where they watch over pumps and valves. These places can often be in remote locations. This helps keep the public water safe to use.

You will also find PLCs in traffic light control systems, elevators, and car washes. To put it simply, almost any process that needs a reliable, repeatable, and automatic way to control things will use a PLC. This makes them one of the most useful tools in modern automation.

Beginner’s Guide to Getting Started with PLCs

Getting started with PLCs may look hard at first, but with the right plan, it can be done. This simple guide will take you through the first steps, like getting your equipment and picking the controller that fits your project. The first thing is to have a basic idea of what a PLC system is and what pieces go with it.

If you want to meet industry demands, you must get real hands-on experience. You can do this by working with real hardware and using programming software while you build and try out some easy automation tasks. We will show you what you need to get started with PLCs and how you can choose what works best for you.

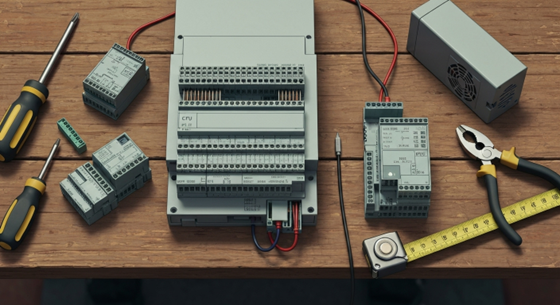

Essential Equipment and Resources Needed

To start your work with PLCs, you need some basic gear. The main thing to have is the PLC. If you are new, it is a good idea to get a small PLC or a starter kit from one of the big brands. That is a simple and cheap way to learn the basics of plc programming.

You also need a computer that can run the plc programming software. You use this software to write, test, and put the plan you make into the PLC. Many makers give free or trial programming software, which is very good when you are learning. Some jobs may be better if you add a Human-Machine Interface (HMI), as it helps you see data and run the process.

Here is a simple list of what you need:

• A PLC controller (a small, fixed model is good when you start)

• A power supply that works with the PLC

• A personal computer (PC)

• PLC programming software

• Cables that link the PC and the PLC

Choosing the Right PLC for Your Project

Choosing the right PLC is very important to make your automation project work well. You should make the decision based on what your project needs. First, figure out how many inputs and outputs you need, and what kind they should be. Ask yourself if you only need to read simple on/off switches or if you will be tracking things like temperature and pressure.

Next, look at how hard the control of machinery will be. If it is a simple job, a basic PLC with less memory and speed can be enough. But if you have more complex operations, you will need a stronger PLC that has more memory and can work faster. Plant engineers often write down all their needs first to make sure they pick the right PLC for the job.

You should also think about communication requirements. Will the PLC need to talk to other devices, networks, or an HMI? Make sure the PLC you pick supports the communication protocols you need. Picking a PLC that matches your needs will save you time, let things run smoothly, and stop problems from happening later on.

Step-by-Step Guide to Setting Up and Programming a PLC

Setting up a PLC for the first time has two main steps. First, you need to install the hardware. Next, you set up the software. The steps you follow are simple if you go one by one. You start by making the physical connections. After that, you write your first program. Each part helps you move forward in the setup.

When using programming software, you will make instructions for the PLC. Most people use ladder logic for this step. Modern PLCs have easy integration. This makes setting up a simple system quick and simple. You can find a step-by-step guide in this section to help you get started.

Step 1: Setting Up Your PLC Hardware

The first thing you need to do is set up your PLC hardware the right way. Start by putting the PLC in a good spot. It should be in a safe place, inside an enclosure if you can. This will help keep out dust and water. There needs to be enough air coming in so the PLC does not get too hot, because these industrial computers can heat up when they work.

Next, you need to set up the physical connection for power. Connect the right DC or AC power source to your PLC's power terminals. Be sure to follow the plan from the company that made it. Getting the wires right is important for safety and to make everything work as it should. It’s good to also connect your PLC to a ground. This step will keep out electrical noise, which can mess up how your PLC works.

Last, hook up your input and output devices to the right I/O modules on the PLC. Put your sensors and switches on the input side. For the output side, connect things like motors, lights, or valves. Afterwards, check every wire to make sure they are tight and in the right spot.

Step 2: Writing and Testing a Basic Program

Once you have set up all your hardware, you can start to write your program. Open the PLC programming software on your computer. Create a new project in the program. Most people who are new to this use ladder logic, which is a way of writing code that looks like a relay logic electrical drawing. There are other types too, like function block diagrams (FBD) and structured text.

Try starting with a simple program. For example, you can make a program that turns on a light when you press a button. Use the software's tools to set this up. You need to tell it which part is the input (the button) and which is the output (the light). Doing this basic task helps you see how inputs, logic, and outputs work with each other.

When your program is ready, download it into the PLC. Then put the controller in "Run" mode. Test the setup in real time. Press the button to see if the light comes on. Many plc programming software systems have tools to help you watch or track the logic as it works, and this can help you to debug any problems.

Step 3: Deploying and Troubleshooting Your Automation System

After you test your program and see it works well, you can put your automation system in place. This means you will install the PLC and the connected devices where they need to be for work. Make sure all the wiring is safe, tight, and well protected before you turn the system on for the first real run. At this time, you should watch how it works to see if all things are going as they should in real time.

Even if you have a good plan, some problems can still come up. Troubleshooting is an important skill to have when you work with automation. When you get a problem, it could be the hardware, the software logic, or maybe the wiring. You get the best results from process control and even with complex operations when you take things step by step to find what is wrong.

Here are some common troubleshooting steps:

• Check Physical Connections: Make sure all wires are tight and each one goes to the right spot.

• Verify Power: See if the PLC and all I/O devices get the right amount of power.

• Monitor the Program: Use programming software to watch the logic happen in real time and check that it runs the way you set it up.

• Isolate the Problem: Check each part on its own to find what part is bad and help the machine performance get better.

PLC Programming Basics

PLC programming is the process where you make a list of steps that a PLC follows to do a job on its own. To do this, you use special programming software and pick from a few standard programming languages. This work may sound tough, but the languages try to be clear and easy to use, most of all for people who have worked in electrical or industrial fields.

The best-known language is ladder logic. There are other options too, like function block diagrams and sequential function charts. Each of these gives you a different way to plan and handle your control logic. Now, let’s look at the most used programming languages and talk about a few basic tips for anyone just starting out.

Most Common PLC Programming Languages

There are five main PLC programming languages that the IEC 61131-3 standard lists. This helps programmers pick the best one for the job they need to do. In North America, the most popular choice is Ladder Logic (LD). Ladder Logic is a graphical language that looks like relay logic circuits. This design helps many electricians and technicians understand it easily.

There are other graphical PLC programming languages you can use as well. For example, Function Block Diagrams (FBD) show logic as blocks that connect by lines. Another choice is Sequential Function Charts (SFC). SFC is great when you need to show a step-by-step process.

You can also choose text-based languages for plc programming. Structured Text (ST) is a text-based language that is a lot like something you will see in other program languages, such as Pascal. Another one is Instruction List (IL), which looks almost like the assembly code you find at a low level.

Here are the most common plc programming languages:

- Ladder Logic (LD): This is a graphical language that comes from relay circuit diagrams.

- Function Block Diagram (FBD): It shows functions as blocks that you connect with lines.

- Sequential Function Chart (SFC): This is like a flowchart and works well for step-based processes.

- Structured Text (ST): This high-level text language is great if you have to write complex logic.

- **Instruction List (IL

Best Practices for Beginner Programmers

As with any kind of programming, it is best to follow the best practices from the very beginning. This will help your PLC programming be much smoother. Your programs will also be more reliable with this way. If you are new to plc programming, one of the top things you need to do is to add comments to your code. Make sure you explain what each line or rung is doing in the logic. This will help you and others understand it later. It also makes finding and fixing problems easier.

It is important to make your program logical. Group logic that is about the same thing into their own sections or subroutines. For example, you can keep things like alarm handling, operator controls, and machine actions each in their own section. Keeping your program in order like this makes it easier to read, change, and debug. You should start simple, then add more steps or details as you go.

Safety is something you must always think about. While a safety plc is there for very important safety needs, you should also write normal PLC programs to be safe first. Think about what should happen if a sensor does not work or the power goes off. You want your code to always make the machines or systems safe if something goes wrong.

Comparing PLCs to Traditional Relay Control

Before PLC automation was common, control systems in factories and plants used old relay control systems. These used many electromechanical relays that worked together to follow relay logic. These setups did the job well at that time, but they took up a lot of space. They also were not easy to change and needed a lot of wiring.

In the late 1960s, things changed. The PLC came in and changed how the industry worked. The main difference is that a PLC uses software and not the old relay logic wiring. This change brought more speed, more options, and made automation work better for everyone.

Differences in Functionality and Efficiency

The difference between relay logic and modern PLCs is big. In relay logic systems, everything is hooked up with wires. If someone wants to change how things work, they must go to the control panel and move the wires. This job takes a lot of time, costs more money, and people can make mistakes.

Modern PLCs do things another way. The logic in PLCs gets handled using software on a computer. When you want to change something, the programmer writes new code and sends it straight to the PLC. This lets PLCs change and adapt fast to new needs. It’s one reason why PLCs now get used much more than relay logic systems.

PLCs also handle lots of complex tasks that are very hard for old relay setups. Timers, counters, math, and data handling are all part of what PLCs do. So, automation gets easier and better.

- Flexibility: With PLCs, you change things using software. Relay systems need someone to move the wires by hand.

- Complexity: PLCs can take care of complex tasks and detailed logic. Relay logic can only do simple jobs.

- Size: One PLC can do the same work as hundreds of relays. This means you save a lot of space.

- Reliability: PLCs don’t have parts that move around, so they are more reliable and need less fixing than relays.

- Cost: For bigger or more difficult systems, PLCs

Advantages of Using PLCs in Automation

The use of PLCs in automation has many good points. One of the main reasons people choose PLCs is that they last for a long time and do not break easily. They have a tough, robust design and no moving parts, so they work well in harsh industrial environments. This means less downtime. You get steady machine performance all year round.

PLCs are also flexible. If production needs to change, you can update them quickly to fit new processes. It is easy to connect PLCs with other tools and systems like HMIs or SCADA. This easy integration helps your control systems work together as one, making the full setup stronger and better.

With PLCs, you can watch and control many things at the same time. They handle lots of inputs and outputs with real know-how. PLCs give you live updates about machine performance, so you can work faster and make good use of time and resources. This helps you move closer to higher productivity in any industrial space.

- Increased Reliability: They have a strong solid-state design, so they break down less often and last longer than mechanical relays.

- Greater Flexibility: You can change their program or setup easily when tasks, jobs, or processes need tweaking.

- Lower Costs: These save money on wiring, parts, and taking care of the equipment.

- Enhanced Capabilities: PLCs let you do extra things, like keep track of data, have better communication between machines, and do

Skills and Certifications for Working with PLCs

To grow a career in industrial automation, you need to have good skills with PLCs. Plant engineers, technicians, and programmers often get special training and certificates to show their skills and keep up with new technology.

Having these certificates shows that you know what you are doing. Many employers look for people with these skills. You can choose to get certificates based on a certain brand or on general skills in industrial automation. When you spend time to learn more and improve yourself, you will have more chances to find good jobs in this fast-growing field.

Recommended Training and Certifications

If you want to work with PLCs and be good at it, the best way is to get real training and certifications. Many big PLC makers, including Rockwell Automation (Allen-Bradley) and Siemens, have programs that teach you everything you need to know. These courses go from starting out with basic programming all the way up to more advanced things. People in the field trust these certifications. If you have a certification from Rockwell Automation, it will show others that you have strong skills.

Besides training from companies like Rockwell Automation, a lot of community colleges and technical schools have classes where you can get certificates or a degree in automation technology or industrial work. These courses help you learn both why PLCs work the way they do and how to use them in real life.

You can also find special safety PLC certifications, which teach you about programming systems that keep people and equipment safe. Learning never stops, so it’s smart to pick classes and courses that fit your job goals.

- Vendor-specific certifications (e.g., Rockwell Automation, Siemens)

- Automation technology programs at community colleges

- Online courses and tutorials from educational platforms

- Specialized training in areas like motion control or process safety

For more details, check:

https://www.rockwellautomation.com/en-us/support/training/plc-training.html

Key Skills for Industrial Automation Professionals

Working in industrial automation takes many skills. It is not just about PLC programming. A strong knowledge of process control is very important. You have to know how the machines and all the steps work before you can make control logic that works the right way.

You must also have good problem-solving and troubleshooting skills. When something goes wrong, you have to check things step by step. You should look at the hardware, software, or network to find where the problem is. This skill is needed by many employers.

It is important to know other parts of the field too. You often work with HMI and SCADA systems, industrial networks, sensors, and electric motors. If you know how all these things work together in a big automation system, you can be better at your job and more useful in industrial automation.

Conclusion

To sum up, learning how to work with PLC automation is very important if you want to do well in today’s industrial world. As you saw, knowing the parts and workings of programmable logic controllers can help you plan and use better automation systems. It does not matter if you are new to this or if you have been working for many years. The tips in this guide are here to help everyone. Keep in mind that you need to keep learning, and working with your hands is also important to get good at plc programming. If you want to move forward in your automation career, look for training that will help you get more knowledge and skills.

Frequently Asked Questions

How does a PLC differ from a microcontroller or PC?

The main difference is that a programmable logic controller is one of the industrial computers made to handle control tasks in tough places. The strong and robust design, real-time operating system, and scan-based way it works set it apart from normal computers and microcontrollers. These other kinds of devices are not made to work in difficult conditions like a programmable logic controller.

What industries use PLC automation most frequently?

PLC automation is used a lot in many places like the manufacturing and automotive industries. It is also be found in food processing, energy plants, and many remote locations. PLCs help with process control in places such as water treatment plants. They are part of the control systems in almost every field that needs industrial automation.

How is PLC programming typically performed?

PLC programming is carried out using programming software on a PC. The language used most often is ladder logic. This method uses simple pictures that make it easy to learn. There are other languages, such as function block diagrams, that people use as well. You can create and check your programs in real time with these tools.

What are the main benefits of using PLCs in automation?

PLCs offer many good benefits for automation. They have a strong and robust design that makes them reliable. You can reprogram them with ease, so they are flexible and fit different needs. Using PLCs also helps save costs for people and companies.

They make control systems better because they allow easy integration with other devices. PLCs can handle complex tasks quickly and with precision. This makes them a top choice for anyone who wants to work with control systems and get the most out of their automation.