How Automation PLC Revolutionizes Manufacturing Processes

Study PLCs/Automation More or Get Out While I Still Can?

Studying PLCs and automation is essential for staying competitive in today’s manufacturing landscape. As industries increasingly adopt advanced technologies, understanding automation PLC concepts can enhance your career prospects and operational efficiency. Embrace the learning opportunity now to avoid being left behind in an evolving workforce.

Key Highlights

- A Programmable Logic Controller (PLC) is an industrial computer that automates manufacturing processes.

- PLCs operate by reading inputs, executing a program, and controlling outputs to manage machinery.

- Modern PLCs offer advanced features like motion control, data logging, and robust communication protocols.

- They are more flexible and reliable than older relay-based systems, reducing downtime.

- PLCs are programmed using languages like Ladder Logic and Function Block Diagrams.

- Different types, such as fixed and modular PLCs, cater to various industrial applications.

Introduction

In the world of industrial automation, efficiency and precision are paramount. The Programmable Logic Controller (PLC) stands as a cornerstone technology, revolutionizing how manufacturers approach process control. These specialized industrial computers are the brains behind countless automated tasks, from simple machine functions to entire production lines. By providing a flexible, reliable, and easily programmable solution, PLCs have become essential for modern manufacturing, ensuring streamlined operations and enhanced productivity in a competitive industrial landscape. However, implementing PLC-based automation systems can present challenges such as communication errors between devices, difficulties in integrating with legacy equipment, issues with programming logic that lead to unexpected machine behavior, and troubleshooting problems related to faulty wiring or hardware failures. Addressing these common issues is an essential part of successful PLC system deployment and long-term operation.

Understanding Automation PLCs in Manufacturing

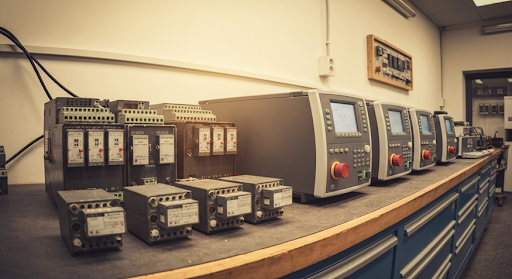

A PLC is a ruggedized digital computer used to automate electromechanical processes. Think of it as the central nervous system for machinery on a factory floor. It is specifically designed to withstand harsh industrial environments, including extreme temperatures, vibrations, and electrical noise.

These powerful control systems monitor inputs from sensors and other devices, make decisions based on their programming, and control output devices like motors and valves. This capability makes PLCs fundamental to managing complex industrial processes with high reliability. The following sections will explain their role and operational mechanics in greater detail.

Definition and Industrial Role of PLCs

A Programmable Logic Controller is an industrial computer built to control and monitor equipment based on custom programming. Since their invention in the late 1960s, PLCs have become the primary automation method for a vast range of industries, effectively replacing older, hard-wired relay logic systems. Their introduction marked a significant shift toward more flexible and efficient manufacturing.

The industrial role of a PLC is to act as the interface between machinery and a control program. It receives data from input devices like switches and sensors, processes this information through its programmed logic, and sends commands to output devices. This allows for precise control of machinery on factory assembly lines, amusement rides, and food processing plants.

Their adaptability allows them to handle not just simple on/off functions but also complex tasks such as motion control, data logging, and high-level communications with other systems. This versatility makes the PLC an indispensable tool for any modern industrial operation looking to optimize its processes.

How PLCs Drive Process Automation

PLCs drive process automation through a continuous, cyclical operation. This cycle consists of three main stages: monitoring inputs, executing the program, and updating outputs. First, the PLC scans the status of all connected input devices, which can include sensors reading temperature or pressure and switches indicating a machine's position. This provides a real-time snapshot of the industrial process.

Next, this industrial computer executes the user-created program stored in its memory. The program, often written in ladder logic, uses the input data to make decisions. For example, if a sensor detects a box is in place, the program logic might decide it's time to activate a stamping mechanism.

Finally, based on the program's logic, the PLC sends output signals to control connected devices. These signals can turn on motors, open valves, or activate warning lights. After updating the outputs, the PLC performs an internal diagnostic check and immediately begins the cycle again. This entire process, known as the scan time, happens rapidly, ensuring responsive and continuous control.

Evolution and Technological Advancements of PLCs

The journey of the PLC began in the late 1960s as a replacement for cumbersome relay panels. Early models were large and offered basic control, but they laid the groundwork for a technological revolution in automation. Since then, PLCs have undergone significant transformations.

Today, modern PLCs are compact, powerful, and packed with features that were once unimaginable. These technological advancements have expanded their capabilities far beyond simple logic control, enabling them to handle sophisticated automation challenges. We will now look at the key milestones in their history and the modern features that define them.

Historical Development and Key Milestones

The historical development of the PLC is rooted in the needs of the American automotive industry. In the late 1960s, General Motors sought a flexible electronic replacement for their hard-wired relay logic circuit systems, which were difficult and time-consuming to reconfigure for new car models.

In response, Dick Morley and his company, Bedford Associates, invented the first PLC in 1968, which they named the Modicon 084 (for "modular digital controller"). This invention is why Morley is often called the "father of the PLC." It provided a rugged, programmable, and easily modifiable controller designed for the factory floor.

This innovation was a game-changer. It allowed engineers to change production logic by reprogramming a device rather than painstakingly rewiring massive relay panels. This foundational milestone paved the way for the widespread adoption of automation and the continuous evolution of control systems in manufacturing.

Modern Innovations Shaping PLC Technology

The capabilities of modern PLCs have expanded dramatically thanks to continuous innovation. Today's controllers are far more than simple logic solvers; they are powerful hubs for data acquisition and communication, central to the Industrial Internet of Things (IIoT). Modern PLC programming software is also more user-friendly and powerful.

These advancements allow for greater integration and control over complex processes. They can communicate seamlessly with HMI (Human Machine Interface) panels, SCADA systems, and enterprise-level networks, providing real-time visibility and control.

Key innovations that shape today’s PLCs include:

- Advanced Communication Protocols: Built-in support for Ethernet, Wi-Fi, OPC UA, and EtherCAT allows for easy integration with a wide variety of devices and systems.

- Enhanced Data Capabilities: Features like data logging, REST API functionality, and robust memory enable PLCs to collect, store, and share vast amounts of process data.

- Integrated Motion Control: Many PLCs now offer built-in motion control capabilities to precisely manage servo systems and variable frequency drives.

Core Components and Architecture of a PLC System

At its heart, a PLC system consists of several key components working together to provide reliable industrial control. The architecture is designed for modularity and functionality, ensuring it can be adapted to specific application needs. The core elements include a central processing unit (CPU), input and output modules, and a power supply.

This fundamental architecture allows a PLC to receive information from the field, process it logically, and execute commands to control machinery. The following sections will break down the functions of the CPU, explain the role of I/O modules, and cover other essential hardware like power supplies and communication units.

Central Processing Unit (CPU) Functions

The Central Processing Unit (CPU) is rightfully called the brain of the PLC system. This microprocessor-based unit is responsible for executing the control program stored in the PLC's memory. It orchestrates all PLC functions, from running logic and performing calculations to managing communications.

One of the CPU's primary jobs is to operate in real time. It continuously runs the scan cycle, reading inputs, processing the user-defined program, and updating outputs with minimal delay. This ensures that the PLC can respond instantly to changes in the manufacturing process, which is critical for safety and efficiency.

In addition to program execution, the CPU handles data acquisition from sensors, performs internal diagnostics to check system health, and manages communication with other devices, such as programming terminals or other PLCs. The power and speed of the CPU directly impact the complexity of the tasks a PLC can handle and its overall performance.

Input/Output (I/O) Modules Explained

Input/Output (I/O) modules are the bridge between the PLC's CPU and the industrial equipment it controls. They convert the electrical signals from sensors and switches into digital data the CPU can understand, and translate the CPU's digital commands back into electrical signals to control output devices. Input devices can include anything from a simple push button to a complex vision sensor.

Output devices are the components that perform an action, such as electric motors, solenoid valves, or indicator lights. The I/O modules ensure that the correct voltage and current levels are used for these physical connections. This separation of I/O from the CPU adds to the system's robustness and flexibility.

I/O can be either digital (discrete) or analog. Digital I/O is like a standard light switch, representing on/off states. Analog I/O is like a dimmer switch, representing a range of values, such as temperature or pressure.

| Module Type | Function | Examples |

|---|---|---|

| Input Modules | Receive signals from field devices and send them to the CPU | Pushbuttons, limit switches, pressure sensors, thermocouples. |

| Output Modules | Receive signals from the CPU and send them to field devices to control an action. | Motor starters, solenoid valves, indicator lamps, alarms. |

Power Supply, Communication Modules, and Expansion Units

A stable and reliable power supply is a critical component of any PLC system. It converts the available AC line voltage into the clean DC voltage required by the PLC's internal components, such as the CPU and I/O modules. This ensures the controller operates consistently and is protected from electrical fluctuations that are common in industrial settings.

Communication modules enhance a PLC's ability to connect with other systems. While many PLCs have built-in ports, these modules add support for various communication protocols like EtherNet/IP, Modbus, or Wi-Fi. This allows the PLC to share data with HMIs, SCADA systems, other PLCs, or even cloud platforms, enabling more integrated and intelligent control.

For applications that grow over time, expansion units are essential. These modules allow you to add more I/O points to a PLC system beyond what the base unit offers. This scalability means you can start with a small system and expand its capabilities as your needs change, accommodating more sensors and actuators, even in remote locations.

Comparing PLCs to Other Control Systems

While PLCs are a dominant force in industrial automation, they are not the only type of control system available. Understanding the main difference between PLCs and other technologies, such as traditional relay-based controls and modern microcontrollers, is key to choosing the right solution for your needs.

Each system has its own strengths and is suited for different environments and tasks. The following comparison will highlight what makes PLCs uniquely suited for the factory floor when measured against older methods and other popular computing platforms.

PLCs vs. Relay-based Controls

Before the advent of PLCs, industrial control was managed by complex panels of hard-wired relays, timers, and sequencers. The main difference between these two systems is flexibility. With relay-based controls, changing the logic meant physically rewiring the entire panel, a time-consuming and error-prone process.

PLCs revolutionized this by replacing physical wiring with software-based logic. Instead of rewiring, an engineer can simply reprogram the PLC, saving immense time and resources. This software-based approach also allows for far more complex and precise control logic than what was possible with mechanical relays.

The advantages of PLCs over relays are clear:

- Reliability: PLCs are solid-state devices with no moving parts to wear out, making them significantly more reliable and durable than mechanical relays.

- Flexibility: Logic can be easily modified and updated through programming without any hardware changes.

- Capability: PLCs can handle advanced functions like mathematical calculations, data logging, and communication, which are beyond the scope of simple relays.

PLCs vs. Microcontrollers and Embedded Controllers

In recent years, low-cost microcontrollers and open-source embedded controllers like Arduino have become popular for hobbyist projects and some commercial products. However, there is a distinct difference when comparing them to an industrial computer like a PLC. Microcontrollers are typically single integrated circuits containing a processor, memory, and I/O.

While attractive for their price, standard off-the-shelf microcontrollers are not designed for industrial settings. They lack the ruggedness to withstand the vibrations, temperature ranges, and electrical noise common on a factory floor. Using one in such an environment is, as AutomationDirect notes, "just downtime waiting to happen." [Source: https://www.automationdirect.com/adc/shopping/catalog/programmable_controllers]

For industrial applications that require the flexibility of open-source platforms, specialized industrialized controllers have been developed. Products like the ProductivityOpen are Arduino-compatible but built with the power and reliability of a PLC. They provide a robust solution that combines the best of both worlds, proving that PLCs remain the standard for serious industrial automation.

Common Types of PLCs and Their Applications

PLCs come in various shapes and sizes, each designed to meet different industrial application requirements. The most common types are generally categorized as fixed, modular, and rack-mounted PLCs. Choosing the right type depends on factors like the number of I/O points needed, the complexity of the control task, and the potential for future expansion.

From simple, standalone machine control to large, distributed systems, there is a PLC type suited for the job. Understanding the differences between these forms is the first step in selecting the ideal controller for your manufacturing needs.

Fixed, Modular, and Rack-Mounted PLCs

Different PLC types offer distinct advantages in form and function. The choice between them often comes down to the scale and complexity of the automation task.

- Fixed PLCs: Also known as brick or compact PLCs, these units have the processor, power supply, and a fixed number of I/O points all in one housing. They are small, affordable, and ideal for simple, standalone tasks or small-scale applications where space is limited and expansion is not a concern.

- Modular PLCs: These PLCs are designed for flexibility and scalability. The CPU, power supply, and I/O modules are separate components that plug into a base or rack. This allows you to customize the system by adding or changing modules to fit your exact needs. This type is perfect for applications that may grow or change over time.

- Rack-Mounted PLCs: This is a type of modular PLC designed for the most demanding and complex applications. They are mounted on a larger rack that can hold a high number of I/O modules and powerful CPUs, supporting thousands of I/O points for large-scale process control.

Choosing the Right PLC for Different Manufacturing Needs

Selecting the right PLC is crucial for the success of your automation project. The choice depends entirely on your specific application requirements. For smaller projects with a limited number of inputs and outputs, a fixed or "brick" PLC like the CLICK series might be the most practical and cost-effective choice. Their compact size and simple programming make them ideal for beginner projects or standalone machines.

For more complex tasks that require more I/O, advanced features, or future scalability, a modular PLC is the better option. Systems like the Productivity series allow you to mix and match modules for analog, digital, and communication needs. This scalability ensures that the PLC system can grow with your operations without needing a complete overhaul.

When making your decision, consider factors like the number and type of I/O points, memory and processing power needed for your program, communication requirements, and the physical environment. Evaluating these needs will help you choose a PLC that not only meets your current demands but also provides a solid foundation for future growth.

PLC Programming Languages and Methodologies

A key advantage of PLCs is their support for various programming languages, which allows developers to choose the best method for their application and skill set. The International Electrotechnical Commission (IEC) has standardized five main languages for PLC programming, ensuring a level of consistency across different brands.

These languages range from graphical, visual formats to text-based code. The most common is Ladder Logic, but others like Function Block Diagrams and Structured Text are widely used for different types of control tasks. We will now explore these popular programming methodologies.

Ladder Logic and Function Block Diagrams

Among the different PLC programming options, two graphical languages are particularly popular due to their visual and intuitive nature. These are Ladder Logic and Function Block Diagrams.

- Ladder Logic (LD): This is the most widely used PLC programming language. It is designed to look like the electrical relay logic diagrams that it replaced, making it easy for electricians and technicians to understand and use. The logic is represented by rungs on a ladder, with contacts (inputs) on the left and coils (outputs) on the right.

- Function Block Diagrams (FBD): This is another graphical language that uses blocks to represent functions like timers, counters, or mathematical operations. Lines connect the inputs and outputs of these blocks to create the control logic. FBD is very useful for visualizing signal flow in process control applications.

Both languages are offered in popular PLC programming software and provide a straightforward way to develop and troubleshoot control systems, especially for those with a background in electrical schematics.

Structured Text and Sequential Function Charts

For more complex applications, text-based and sequential programming languages offer greater power and flexibility. Structured Text (ST) is a high-level, text-based language similar to Pascal or C. It is excellent for handling complex mathematical calculations, data manipulation, and looping, which can be cumbersome to implement in graphical languages like Ladder Logic.

Another powerful language is Sequential Function Charts (SFC). This is a graphical language used to program processes that occur in a specific order or sequence. It breaks down a complex process into a series of steps and transitions. Each step represents a state in the process, and a transition is the condition that must be met to move from one step to the next.

This methodology is ideal for managing batch processes or machine operations that follow a defined cycle. Using the right programming software, developers can leverage these advanced languages to create highly efficient and organized control programs.

Real-World PLC Applications and Case Studies

The impact of PLCs is visible across nearly every industry. From massive industrial applications on assembly lines to emerging uses in home automation, their versatility is a key reason for their widespread adoption. PLCs are the workhorses behind the scenes, ensuring processes run smoothly, efficiently, and safely.

Specialized controllers, such as a safety PLC, are designed for critical applications where human safety is paramount. The following examples will illustrate just how integral PLCs are in both traditional industrial settings and new, innovative fields.

Industrial Examples: Assembly Lines and Packaging

In industrial settings, PLCs are the backbone of automation. Their ability to precisely control sequences, timing, and motion makes them indispensable for a variety of tasks that require high speed and repetition.

Some prominent industrial examples where PLCs are fundamental include:

- Manufacturing Assembly Lines: PLCs control the entire production sequence, managing robots, conveyors, and other machinery to assemble products from start to finish. They ensure each step happens in the correct order and at the right time.

- Packaging and Material Handling: In packaging plants, PLCs control machines that fill, seal, label, and box products. They manage the flow of materials and ensure quality control throughout the process.

- Process Control: In industries like chemical processing or water treatment, PLCs monitor and regulate variables such as temperature, pressure, and flow rates. They control electric motors, pumps, and valves to maintain optimal conditions.

Home Automation and Emerging Applications

While PLCs are most known for their industrial prowess, their principles are also being applied in other areas, including home automation. A PLC's ability to handle inputs, execute logic, and control outputs is perfectly suited for managing smart home features like lighting, HVAC systems, and security. Their robustness offers a level of reliability that consumer-grade electronics often lack.

The development of industrialized, open-source compatible controllers is further blurring the lines between industrial and hobbyist applications. These devices allow for sophisticated control in remote locations or environments with wide temperature ranges, opening up new possibilities in agriculture, environmental monitoring, and other emerging fields.

As technology evolves, the core functionality of PLCs will continue to find its way into new and innovative applications. Their proven reliability and adaptability make them a strong candidate for any system that requires dependable automated control, whether in a factory or a smart home.

Conclusion

In summary, Automation PLCs are pivotal in transforming manufacturing processes, enabling greater efficiency, flexibility, and reliability. By understanding the components, evolution, and various applications of PLC systems, businesses can harness the full potential of this technology. Whether it’s optimizing assembly lines or venturing into home automation, PLC innovation continues to shape the future of manufacturing. If you're ready to enhance your operations through automation, don't hesitate to reach out for a consultation. Embrace the revolution of manufacturing and discover how Automation PLCs can elevate your business today!