Best Practices for Implementing Automation PLC Solutions

Key Highlights

- A programmable logic controller (PLC) is the foundation of most automation systems, offering robust control for machinery, process control, and complex tasks.

- PLCs use ladder logic and other programming languages to provide real-time supervision, motion control, and data acquisition across industries.

- Selecting an appropriate PLC requires matching system capabilities, program logic, and communication protocols to your specific industrial application.

- Modern PLCs integrate easily with SCADA systems and human machine interfaces for seamless monitoring and control.

- Both hardware architecture and programming methods are crucial for successful implementation and troubleshooting of automation solutions.

- PLCs have evolved to meet demanding applications, supporting remote locations and advanced motion control for assembly lines and food processing.

Introduction

Industrial automation relies on programmable logic controllers to manage critical tasks and processes. A PLC system serves as the central brain for automated control, executing a control program to streamline operations, enhance reliability, and reduce manual intervention. Whether you’re overseeing an assembly line or managing temperature control in a food processing facility, PLCs bring flexibility and scalability to modern automation. This article explores best practices for implementing PLC solutions, ensuring you select and configure the right controller for your industrial needs.

Understanding PLCs in Industrial Automation

PLCs are at the heart of industrial automation, bridging the gap between input devices and output devices to create efficient control systems. They read signals from sensors and switches, then decide how to manage connected machinery using programmable logic. This real-time approach enables precise process control, allowing you to automate complex industrial tasks with confidence.

Understanding how a programmable logic controller operates is essential for anyone tasked with deploying or maintaining an automation system. Let’s break down what PLCs are and how they work in modern industrial environments.

Definition and Basic Working Principle of PLCs

A programmable logic controller is a digital computer customized for controlling industrial processes and machinery. Its processing unit receives signals from input devices like sensors and switches, evaluates the data according to the control program, and sends output signals to actuators, motors, or valves. This cycle drives real-time automation, ensuring every connected output device operates as intended.

You’ll find PLCs handling tasks such as starting an electric motor, opening a valve, or sounding an alarm beacon. The system checks the state of all input devices, executes the PLC program logic, and adjusts output signals accordingly. For instance, if a temperature sensor indicates the need to cool a system, the PLC will activate a cooling fan by sending the right signal to its output device.

PLCs run through these operations continuously, performing internal diagnostics between cycles to maintain system safety and reliability. This real-time control is what makes PLCs vital to automation systems.

Evolution of PLC Technology in Automation

PLCs have come a long way since their introduction in the late 1960s. Bedford Associates developed the first PLCs for General Motors to replace unreliable hard-wired relay logic systems in industrial processes. These early controllers were large, costly, and complicated to program or maintain, but they solved a critical problem by providing flexible, rugged, and easily programmable control.

As technology advanced, PLCs evolved into medium and small devices, offering modular designs for easier expansion and customization. Modern PLCs now incorporate powerful microprocessors, extensive memory, and integrated communication protocols, allowing for sophisticated automation solutions that can handle complex data, real-time decision-making, and remote monitoring.

Today’s PLCs support advanced features like motion control, analog inputs, and seamless integration with SCADA systems, making them indispensable in industries ranging from automotive assembly lines to food processing plants.

Key Functions and Advantages of Using PLCs

PLCs deliver a broad spectrum of control functions for industrial applications, enabling you to automate everything from simple machinery to complex tasks. Their real-time process control and ability to manage multiple inputs and outputs make them highly effective for increasing productivity and accuracy. Compared to conventional control systems, PLCs offer greater reliability, flexibility, and ease of modification, supporting the evolving requirements of modern industrial environments.

Understanding the core functions and major advantages of PLCs highlights why they are the primary automation method in today’s factories and processing centers.

Core Functions Performed by PLCs

PLCs excel at orchestrating the control of machinery, motion control, and supervisory functions within an automation system. Their primary roles include monitoring input devices, executing data acquisition, and directing output devices such as motors or valves. This allows the PLC to manage everything from simple start/stop operations to complex sequencing and interlocks required for advanced manufacturing.

For example, a PLC can control the speed and direction of a motor through motion control modules, oversee data logging for quality assurance, or govern safety procedures in a factory using specialized safety PLCs. These controllers are also responsible for real-time adjustments, ensuring that processes run smoothly and deviations are corrected instantly.

By performing these automation tasks, PLCs deliver precise, reliable, and scalable control, which is essential for competitive industrial applications.

Benefits Over Conventional Control Systems

PLCs offer several significant benefits compared to traditional control systems and industrial computers:

- Real-time operation provides immediate system feedback and adjustment, crucial for process control.

- Modular design allows scalability and easy troubleshooting, minimizing downtime during maintenance.

- Enhanced durability ensures reliable performance in harsh industrial environments, including resistance to temperature variations, electrical noise, and vibration.

- Safety PLCs offer added protection for personnel and equipment, integrating advanced safety functions.

The main difference between PLCs and older relay-based control systems is flexibility. PLCs are easily reprogrammed to accommodate changes in process requirements, whereas hard-wired systems require extensive manual rewiring. As Steve Hechtman, founder of Inductive Automation, says, “PLCs empower industrial professionals to ‘dream it, do it’ with exceptional versatility.” This adaptability positions PLCs as the preferred solution for evolving automation needs.

Selecting the Right PLC for Your Automation Project

Choosing the right PLC system for your automation project requires careful consideration of your control program, hardware needs, and desired industrial applications. The PLC programming software, program logic, and available communication ports must match your operational environment and application scale. Whether you’re setting up a small assembly line or a large food processing facility, the right selection ensures efficient and reliable automation.

Let’s examine the key factors to consider and how to match PLCs to your specific requirements.

Factors to Consider When Choosing a PLC

Selecting a PLC involves evaluating environmental and operational parameters to ensure optimal performance and reliability. Consider these key factors:

- Temperature ranges: Choose PLCs rated for the expected operating environment to avoid failures due to overheating or freezing.

- Electrical noise: Industrial environments with high electrical interference require PLCs with noise immunity and robust shielding.

- Power supply: Match the PLC’s power requirements to your plant’s available voltage and current capacities.

- Communication ports: Ensure the PLC supports necessary protocols (Ethernet, serial, USB) for integration with remote locations and devices.

Assess the physical space available for installation, future expansion needs, and ease of maintenance. For remote or distributed applications, robust communication and power supply options are essential. Each factor directly impacts system uptime and the overall success of your automated solution.

Matching PLCs to Application Requirements

Aligning your PLC system to specific application requirements is critical for successful implementation. Complex tasks, such as coordinating multiple output devices or managing analog inputs, demand higher processing power and advanced programming capabilities. For example, assembly lines often require motion control modules and rapid data acquisition, while food processing facilities prioritize temperature control and real-time monitoring.

Choose modular PLCs for scalable operations or compact PLCs for space-constrained environments. Programming device compatibility and available PLC programming languages also affect your ability to tailor the control program. When requirements evolve, modular PLCs allow for easy expansion and system upgrades.

Matching the PLC system’s hardware and software features to your application ensures efficient operation, consistent process control, and adaptability to future changes.

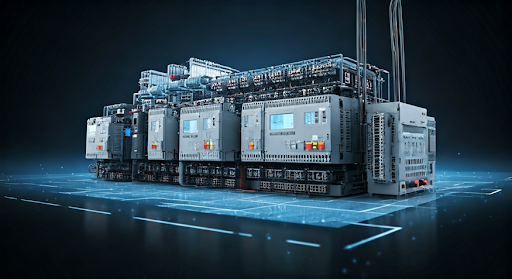

Components and Architecture of a Typical PLC System

A standard PLC system consists of essential hardware components and a robust architecture designed for industrial automation. The power supply, processing unit, input and output devices, and programming device are interconnected through physical connection and communication protocols. Understanding the PLC architecture is vital for selecting, installing, and maintaining reliable automation systems in any industrial setting.

Next, we detail the fundamental hardware components and system architecture you’ll encounter in a typical PLC setup.

Main Hardware Components of a PLC

PLCs feature several key hardware elements, each fulfilling a specific role in the automation system. The following text table illustrates the primary components:

| Component | Description |

|---|---|

| Power Supply | Provides stable voltage and current for all PLC modules, adapting AC to DC as required. |

| Processing Unit | Acts as the brain, executing the control program and managing data processing and communication. |

| Input Devices | Sensors, switches, and other devices that send signals to the PLC for monitoring and control. |

| Output Devices | Actuators, motors, valves, and indicators that receive control signals from the PLC. |

| Programming Device | Interface for writing, editing, and uploading the control program to the PLC. |

Each of these components is designed for rugged industrial use, ensuring reliable operation in demanding environments.

Overview of PLC System Architecture

Typical PLC architecture connects hardware components via physical interfaces and communication ports, enabling real-time control and integration. The power supply ensures consistent operation across all modules, while the central processing unit communicates with input and output devices using standardized protocols.

Connected output devices, such as motors, respond immediately to control signals, while input devices provide feedback to the processing unit for ongoing supervision. Human machine interfaces (HMI) may be incorporated for operator interaction, allowing manual overrides or status monitoring.

This architecture supports seamless integration with SCADA systems and remote locations, offering flexibility for complex industrial processes. Understanding the relationships and physical connections among components helps you design and maintain robust automation solutions.

PLC Programming Languages and Methods

Programming a PLC requires selecting the appropriate language and method for your system’s complexity and application type. Ladder logic is the most widely used, but function block diagrams and structured text offer alternatives for advanced program logic and complex data processing. PLC programming devices and software provide the tools you need to configure, test, and modify control systems for industrial automation.

Let’s explore the most common PLC programming languages and how they differ in application and functionality.

Common PLC Programming Languages Explained

Several programming languages are available for configuring PLCs, each with strengths suited to specific tasks:

- Ladder Logic: Mimics electrical relay diagrams, ideal for straightforward control tasks and easy troubleshooting.

- Structured Text: Enables complex mathematical and logical operations using standard programming syntax.

- Function Block Diagrams: Visualize control logic using interconnected blocks for intuitive programming.

- Instruction Lists: Provide low-level programming for rapid execution and minimal memory usage.

Programming devices and PLC programming languages allow engineers to tailor automation systems to their needs. Ladder logic is particularly accessible for technicians, while structured text is preferred for sophisticated calculations and data handling. Function block diagrams simplify complex algorithms, supporting diverse industrial applications.

Differences Between Ladder Logic, Structured Text, and Others

Ladder diagrams are graphical, with rails and rungs representing power and control logic, making it easy for users familiar with electrical systems to design and troubleshoot programs. Ladder logic excels in simple, repetitive tasks and is widely adopted due to its intuitive format.

Structured text, on the other hand, uses a textual approach similar to high-level programming languages, allowing for complex data manipulation, advanced calculations, and flexible program logic. This language suits large-scale projects requiring intricate control algorithms.

Function block diagrams combine graphical elements and logic blocks, streamlining the programming of multi-step processes. The main difference among these languages is their suitability for different levels of complexity and user expertise. By choosing the right language, you can optimize PLC program efficiency and adaptability.

Steps for Effective PLC Programming and Implementation

Implementing PLC programming involves a defined sequence of steps, from writing control logic to testing and validating the final program. Using ladder logic or structured text, you create a program tailored to complex tasks and automation system requirements. Rigorous testing and debugging ensure reliable operation and safety, minimizing downtime and errors.

Understanding this workflow is crucial for successful automation deployment. Next, we look at the programming sequence and best practices for validation.

Sequence of Programming a PLC for Automation Tasks

Programming a PLC follows a structured process to ensure accurate and efficient automation:

- Define automation system requirements, identifying input and output devices and desired control logic.

- Use a programming device and PLC programming software to write the control program in ladder logic, structured text, or function block diagrams.

- Upload and configure the PLC program, linking it to the hardware for real-time operation.

- Test the system, verifying correct input and output responses and adjusting logic as needed.

Each step is essential for translating industrial automation needs into a reliable, executable control program. By following this sequence, you ensure your PLC system meets operational goals while supporting easy modification for future requirements.

Testing, Debugging, and Validation Best Practices

Thorough testing, debugging, and validation are vital for reliable control systems. Begin by simulating input and output responses using PLC programming software before live deployment. Identify and correct errors, verify signal integrity, and validate process control logic against real-world scenarios.

Regular validation ensures that updates or modifications maintain system performance and safety. Use diagnostic tools to monitor PLC cycles, check for communication port errors, and review data acquisition logs for anomalies. Systematic testing reduces troubleshooting time and prevents costly downtime.

As Travis Cox, Co-Director of Sales Engineering at Inductive Automation, says, "You’ll not only learn a dozen ways to use this versatile tool, you’ll also be able to think up exciting ways to apply it in your enterprise." Adopting best practices for debugging and validation keeps your automation system running smoothly.

Communication and Integration in PLC-Based Automation

Effective integration of PLCs with other automation devices, sensors, and industrial computers relies on robust communication protocols. Modern controllers connect seamlessly to SCADA systems, enabling centralized supervision and data exchange across sensors and actuators. This connectivity supports advanced process control and real-time decision-making for automated systems.

Exploring how PLCs interact with sensors, actuators, and other devices helps maximize efficiency and system reliability.

How PLCs Interact with Sensors, Actuators, and Other Devices

PLCs use a variety of communication protocols to interface with sensors, actuators, and output devices, supporting complex industrial operations:

• Sensors provide input signals for monitoring conditions such as temperature, pressure, or motion.

• Actuators receive output signals from the PLC, executing actions like opening valves or starting motors.

• Communication protocols (Ethernet, Modbus, OPC UA) enable data exchange with SCADA systems and remote devices.

• Connected output devices respond instantly to PLC instructions, ensuring precise control across distributed systems.

Integration with SCADA systems allows operators to monitor and adjust processes in real time, improving efficiency and safety. Advanced PLCs also support remote access, facilitating troubleshooting and maintenance from distant locations. This seamless interaction forms the backbone of modern industrial automation.

Conclusion

In summary, implementing automation PLC solutions can greatly enhance the efficiency and reliability of industrial processes. By understanding the key functions of PLCs and selecting the right system for your specific needs, you can reap the benefits of modern automation technology. Remember, effective programming and thorough testing are essential to ensure optimal performance. As you explore the world of PLCs, it's crucial to stay updated on the latest innovations and trends that could further streamline your operations. If you're ready to elevate your automation projects, connect with us for a free consultation to discuss tailored PLC solutions that meet your business objectives.

Frequently Asked Questions

What types of applications are ideal for PLC automation?

PLCs are perfect for industrial applications such as assembly lines, food processing, temperature control, and automated systems. They excel in environments requiring precise process control, data acquisition, and real-time supervision, making them indispensable in manufacturing, utilities, and complex production operations.

What are common troubleshooting issues when implementing PLCs?

Typical troubleshooting challenges include errors in plc programming, faulty communication ports, electrical noise interference, and data acquisition problems. Identifying and resolving these issues ensures reliable operation and minimizes downtime, keeping your automation system efficient and safe.

What are the latest trends and innovations in PLC technology?

Modern PLCs integrate with advanced automation systems and SCADA platforms, support remote locations, and offer enhanced programming languages like structured text. Emerging trends include IIoT capabilities, edge computing, and standardized communication protocols, driving innovation and expanding PLC versatility in industrial automation.