Understanding Automation PLC: Key Features and Benefits

Key Highlights

- Programmable logic controllers (PLCs) are essential for reliable control systems in industrial automation, handling both simple and complex tasks.

- PLC programming uses intuitive languages like ladder logic, allowing flexible responses to changing industrial applications.

- Modern PLCs support motion control and human machine interface integration for streamlined manufacturing and process control.

- Robust communication protocols enable PLCs to connect seamlessly with input devices, output modules, and supervisory control systems.

- PLCs are designed for harsh environments, providing durability, flexibility, and consistent performance across a wide range of industrial processes.

- From manufacturing to food processing, PLCs are the backbone of

automated systems, driving efficiency and innovation.

Introduction

The programmable logic controller, or PLC, is a specialized industrial automation device built to manage the control of machinery and processes with precision and resilience. Originally developed to replace complex relay-based systems, modern PLCs are now the core of automated plants and factories. They operate seamlessly in demanding environments, handling the logic, data acquisition, and real-time control needed for efficient operation. PLCs play a vital role in ensuring that industrial applications function reliably, safely, and with adaptability to changing production needs.

What Is a PLC in Industrial Automation?

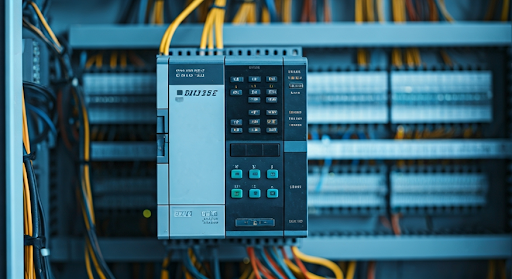

PLCs are rugged, programmable logic controllers that form the backbone of today’s automation system. They interact with input devices—such as sensors or switches—and output devices like motors or actuators to execute control functions that drive industrial processes.

In practical terms, a PLC acts as the “brain” of an automated system, continuously monitoring inputs and controlling outputs according to programmed instructions. This enables precise coordination of machinery, enhancing productivity and accuracy. Curious about how PLCs work in detail? Let’s define their structure and role further.

Defining Programmable Logic Controllers (PLCs)

Programmable Logic Controllers (PLCs) serve as essential components in industrial automation, providing robust solutions for controlling machinery and processes. With a focus on processing units, these controllers utilize sophisticated programming languages, such as ladder logic, to execute complex tasks across various applications—from temperature control in food processing to the operation of electric motors. The versatility of modern PLCs, driven by diverse input and output devices, enables seamless communication within automation systems, ensuring efficient supervisory control and real-time data acquisition to optimize operational efficiencies.

The Role of PLCs in Automated Systems

PLCs serve as the control hub in automated system setups, managing industrial processes efficiently and dependably. Their ability to handle repetitive tasks, monitor equipment, and make decisions based on real-time data transforms industrial operations.

- PLCs facilitate the control of machinery, enabling seamless integration and coordination of diverse equipment.

- They provide robust control systems capable of executing complex logic, timing, and sequencing operations for improved accuracy.

- By automating decision-making, PLCs minimize human intervention, boosting productivity and safety.

Through programmable logic, PLCs bring remarkable flexibility to industrial applications. “PLCs are the workhorses of manufacturing, ensuring that processes run smoothly and adapt to evolving requirements,” says Steve Hechtman, a recognized thought leader in automation. Their advantages lie not only in reliability but also in scalability, making them the first choice for modern automated systems.

Historical Development of PLCs

The concept of PLCs originated in the late 1960s, revolutionizing industrial automation. Bedford Associates and General Motors spearheaded the move away from relay-based control toward digital PLC technology, giving birth to the first PLC. This innovation shifted the industry from cumbersome, wired logic systems to programmable controllers.

Over time, subsequent advancements have refined PLCs into versatile, robust tools. These developments have set PLCs apart from PCs and microcontrollers, optimizing them for industrial environments and ensuring longevity and adaptability.

Early Innovations and Key Contributors

Bedford Associates played a pivotal role in the creation of the first programmable controllers, responding to General Motors' need for a more efficient automation solution. The late 1960s saw these innovators develop the initial PLC, which replaced unreliable and inflexible relay-based systems.

Unlike PCs or microcontrollers, PLCs were designed specifically for industrial automation. While PCs prioritize general computing tasks and microcontrollers offer compact control for embedded systems, PLCs focus on programmable logic and high durability. They are engineered to withstand the rigors of industrial environments, featuring robust construction and real-time processing capabilities.

This specialized approach distinguished PLCs as the primary automation method, setting a new standard for control systems in manufacturing and process industries. The historical shift toward programmable controllers sparked ongoing evolution and expansion of PLC technology.

Evolution From Relay-Based Control to Digital PLCs

Industrial control originally relied on relay-based systems, which were cumbersome and required manual rewiring for changes. The transition to digital PLCs marked a major leap in efficiency and flexibility.

| Control Type | Key Features | Primary Automation Method | Limitations | Advantages of PLCs |

|---|---|---|---|---|

| Relay-Based Control | Physical Relays, hardwired logic | Manual Wiring | Prone to faults, difficulty to modify | None |

| Digital PLCs | Programmable logic, industrials computers | Programmed instructions | Requires programming expertise | Flexible, reliable, scalable |

Digital PLCs, as industrial computers, replaced physical wiring with programmable logic, dramatically improving system modification, troubleshooting, and overall control functions. Today, PLCs are continuously evolving, integrating advanced communication protocols and networking capabilities to further streamline industrial automation. This progress prepares industries for more connected, data-driven operations.

Essential Architecture and Components of a PLC

A PLC system is built on a foundation of vital components, each serving a distinct function to execute automation tasks. The processor unit runs the program logic and manages decision-making, while the memory structure stores code and data. Input modules receive signals from sensors, switches, or other devices, and output modules transmit commands to actuators and machines. The power supply ensures reliable operation across varying industrial conditions. Together, these elements enable PLCs to deliver dependable control in demanding environments.

Processor Units and Memory Structure

The processing unit is the heart of any PLC system, executing program instructions and managing control functions. It acts as the central brain, processing data from input modules and sending commands to output devices. This unit must be robust, capable of handling real-time decision-making in high-pressure industrial settings.

Memory structure is equally vital, as it stores the PLC’s programming, parameters, and system status. The programming device allows operators to input, modify, or download code to the PLC, ranging from simple ladder logic to advanced textual programming languages.

Together, the processing unit and memory form a cohesive platform for automation, offering speed, reliability, and adaptability. Unlike general-purpose PCs, PLCs are optimized for industrial applications, featuring specialized architecture that supports complex automation system requirements.

Input/Output Modules Explained

Input modules connect the PLC to the outside world, gathering signals from input devices such as sensors, switches, and analog inputs. Output modules then send control signals to output devices like motors, heaters, or alarms, enabling physical actions in industrial processes.

- Input modules handle discrete (digital) and analog inputs, ensuring accurate data collection from various sensors and devices.

- Output modules transmit logic-driven instructions to actuators, enabling precise control over connected machinery.

- Communication between modules allows for real-time monitoring and responsive decision-making, essential for safety and efficiency.

PLCs communicate with sensors, actuators, and human machine interface systems using industrial communication protocols. This seamless interaction between input and output modules ensures the PLC delivers optimal performance, maintaining tight control over even the most complex industrial applications.

How PLCs Operate in Industrial Environments

In rigorous industrial environments, PLC systems must execute control functions with real-time precision. They constantly process input signals, make decisions based on programmable logic, and generate output signals to manage machinery and processes. Their reliability stems from robust construction, immunity to electrical noise, and adaptability to a wide range of temperature conditions.

Understanding how PLCs carry out these tasks involves examining the scan cycle and their capacity for real-time control. Let’s explore these integral operations and the role of PLC programming.

Scan Cycle Process Overview

The scan cycle is the fundamental operational process behind control systems in PLC programming. It consists of four main steps: reading input signals, executing the user program, updating outputs, and performing internal housekeeping. This cycle repeats continuously, allowing the PLC to respond quickly to changes in the automation system.

During each scan, the PLC gathers data from all connected input devices, processes the information according to the programmed logic, and modifies output signals accordingly. The scan cycle’s speed is critical, as it determines how swiftly the system can react to events or disturbances.

Programming languages such as ladder logic or function block diagrams are used to define the logic executed during each scan cycle. This structure ensures real-time behavior, delivering reliable performance for industrial processes and automated systems.

Real-Time Control and Decision Making

Real-time operation is a defining feature of PLCs, enabling swift and reliable decision making. As input signals change, the PLC analyzes these updates immediately using its control functions and plc programming software. This rapid response is crucial in environments where safety, efficiency, and accuracy are paramount.

The PLC’s programming allows it to carry out complex instructions, such as timing, counting, or sequencing operations. Decisions are made within milliseconds, ensuring that processes remain tightly controlled and deviations are addressed instantly.

“PLCs are engineered to deliver seamless real-time control, safeguarding industrial applications against costly errors and downtime,” notes Travis Cox, Co-Director of Sales Engineering at Inductive Automation. This capability sets PLCs apart from other controllers and positions them at the forefront of automation technology, ready to adapt to evolving industry needs.

PLC Programming: Basics and Common Languages

PLC programming is the process of creating instructions that tell the automation system how to respond to input conditions and control output devices. Engineers use intuitive programming languages, with ladder logic being the most popular, to design these control functions. Textual programming languages and visual tools like function block diagrams offer additional flexibility for complex logic.

A solid understanding of programming languages and software tools is essential for configuring, troubleshooting, and optimizing PLC performance. Next, let’s look at common programming methods.

Ladder Logic and Structured Text

Ladder logic is the most widely used PLC programming language, resembling electrical relay circuits. It enables engineers to build control functions using graphical representations of switches, relays, and outputs in ladder diagrams.

- Ladder logic is ideal for discrete control applications, such as on/off operations or simple sequencing.

- Structured text provides a textual approach, allowing for advanced programming with familiar constructs like “if-then-else” statements.

- Ladder diagrams and structured text can be combined for greater flexibility, supporting both simple and complex automation system requirements.

Programming software for PLCs typically supports these languages, making it easier for technicians to implement and modify control strategies. This versatility ensures PLCs can address a wide range of industrial processes and adapt quickly as needs change.

Function Block Diagram and Sequential Function Charts

Function block diagrams are another popular PLC programming language, using visual blocks to represent logic functions, data handling, and control elements. Sequential function charts allow engineers to design process flows and step-by-step automation sequences graphically.

These methods excel in handling complex tasks, such as motion control or data acquisition, and enable clear, modular programming. PLC programming software supports both function block diagrams and sequential function charts, offering intuitive tools for configuration and troubleshooting.

With these languages, engineers can customize control logic for specific industrial applications, integrating advanced features and ensuring seamless operation. The combination of programming languages, robust hardware, and modular design cements PLCs as the primary automation method in modern industry.

Key Features and Functions of Automation PLCs

PLCs are renowned for their reliability, flexibility, and robust communication capabilities. They operate across a wide range of temperature conditions and remain resilient in environments with electrical noise or vibration. Advanced PLCs support networking, motion control, and remote monitoring, empowering industrial automation with real-time data and streamlined operations.

Key features like reliability and networking capabilities position PLCs as the preferred choice for diverse industrial settings. Let’s take a deeper look at these essential attributes.

Reliability and Flexibility in Industrial Settings

PLCs excel in reliability, maintaining consistent performance under harsh industrial conditions. Their flexibility allows them to serve a wide range of applications, from simple machine control to complex process automation.

- Built to withstand extreme temperature ranges, PLCs continue working where regular computers would fail.

- Immunity to electrical noise ensures dependable operation in environments with heavy machinery or fluctuating power.

- PLCs can be easily reprogrammed, enabling rapid adaptation to changing process requirements or equipment upgrades.

This combination of reliability and flexibility reduces downtime and maintenance costs, making PLCs an invaluable asset to manufacturers and process industries. Their capability to operate seamlessly across varied industrial environments sets them apart from other control systems.

Robust Communication and Networking Capabilities

Modern PLCs are equipped with advanced communication protocols, enabling integration with SCADA systems, human machine interface devices, and remote locations. They connect effortlessly with sensors, actuators, and other field devices, facilitating real-time monitoring and control.

Networking capabilities allow PLCs to share complex data across the enterprise, supporting distributed automation and centralized management. Communication modules—such as Ethernet, serial, or wireless options—make integration straightforward, whether onsite or across distant facilities.

PLCs also interact with modern IIoT solutions, enhancing bandwidth usage and making data widely available for analysis and optimization. This connectivity drives smarter, safer, and more efficient industrial applications, reinforcing PLCs as the cornerstone of automation systems.

Applications of PLCs in Modern Industry

PLCs are integral to a diverse array of industrial applications, from manufacturing and packaging to food processing and utilities. They automate complex tasks, monitor real-time data, and ensure process consistency across production lines. Their adaptability enables seamless integration with advanced systems such as SCADA and human machine interfaces.

As industries pursue efficiency and innovation, PLCs support scalable, automated solutions. Let’s examine how PLCs are implemented in real-world industrial environments.

Manufacturing, Packaging, and Assembly Lines

PLCs are widely used in manufacturing environments, controlling everything from assembly lines to packaging machinery. Their programmable logic ensures precise coordination, reducing errors and increasing efficiency.

In assembly lines, PLCs manage the sequencing of tasks, monitor sensors, and control output devices such as robotic arms or conveyor belts. Automated system integration enables fast switching between products or processes, allowing for flexible production.

Manufacturers rely on PLCs for tasks that demand accuracy and repeatability, such as filling, labeling, or inspecting products. This consistent control boosts productivity and quality, making PLCs indispensable for modern manufacturing and packaging operations.

Integration with SCADA and HMI Systems

PLCs are essential components in supervisory control and data acquisition (SCADA) systems and human machine interface (HMI) setups. They provide the physical connection between plant floor devices and high-level monitoring platforms.

SCADA systems collect complex data from PLCs, enabling operators to visualize, analyze, and control industrial processes remotely. HMIs allow human operators to interact directly with the automation system, making adjustments or responding to alerts in real time.

PLCs communicate using standard protocols, ensuring seamless integration with SCADA and HMI software. This connectivity enhances oversight, troubleshooting, and process optimization, supporting advanced automation and smarter decision-making.

Selecting the Right PLC for Your Automation Project

This is paragraphChoosing a PLC involves evaluating scalability, performance, brand options, and safety considerations. The right PLC must align with the demands of your automation system, support required control functions, and integrate with existing infrastructure.

Factors such as programming software, expansion capabilities, and reliability play a crucial role. Selecting an appropriate PLC is key to achieving efficient, long-lasting automation in industrial applications. Here’s what you need to consider when making your choice.text. Click it or hit the Manage Text button to change the font, color, size, format, and more. To set up site-wide paragraph and title styles, go to Site Theme.

Factors to Consider: Performance, Scalability, and Brand Options

Selecting a PLC for your project requires careful assessment of several elements:

- Performance: Match the PLC’s processing speed and memory structure to your system’s requirements for real-time control and data handling.

- Scalability: Choose a PLC that supports future expansion, accommodating additional input/output modules or integration with new equipment.

- Brand options: Evaluate widely used brands such as Productivity, CLICK, Do-more, LS Electric, and DirectLogic, each offering distinct programming software and hardware features.

- Safety PLC: Consider specialized safety PLCs for applications requiring strict regulatory compliance and advanced safety functions.

Compatibility with existing automation systems and ease of programming should also guide your decision. Opt for PLCs that offer user-friendly interfaces and strong technical support to simplify setup and maintenance. The right choice ensures reliable, flexible, and scalable automation for your industrial processes.

Conclusion

In conclusion, understanding Automation PLCs is essential for anyone involved in industrial automation. Their key features, such as reliability, versatility, and robust communication capabilities, make them indispensable in modern manufacturing environments. As industries continue to evolve, so too will the role of PLCs, further enhancing operational efficiency and productivity. Selecting the right PLC requires careful consideration of performance and scalability, but the benefits are undeniable. Embracing automation through PLC technology not only streamlines processes but also positions businesses for future growth and innovation. If you're looking to enhance your automation project, don’t hesitate to reach out for a consultation to explore the best PLC options for your needs.