Best Supervisory Control and Data Acquisition Software

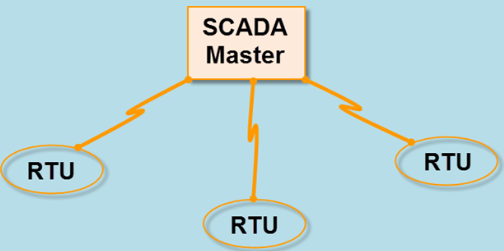

SCADA (Supervisory Control and Data Acquisition) is a type of specialized software that is specifically designed to provide a comprehensive management system for monitoring and controlling industrial processes. HMI SCADA typically consists of software, hardware, and communications networks that enable it to acquire data from multiple sources in real-time and then process the data to manage various operations within the industrial environment. It also enables users to make informed decisions by providing timely alerts and visual feedback.

Robotics technology is quickly becoming a widespread and essential tool that is used in many industries, ranging from power plants to manufacturing and assembly lines. It is being leveraged to carry out a wide range of tasks with greater speed, accuracy, and efficiency than ever before. HMI SCADA is increasingly being leveraged by many different industries to improve efficiency in their operations. These industries include manufacturing, energy, water, and transportation, where SCADA is being widely used to monitor various processes and ensure the most efficient use of resources. The best SCADA software can be applied to automate tedious business processes by easily collecting, sorting, and analyzing data from connected sensors and other devices in an automated fashion. This not only helps save time but also increases the accuracy of the results obtained, making it a powerful tool for businesses. This feature of SCADA technology enables organizations to efficiently analyze and process large amounts of data in a very short amount of time, thus providing them with invaluable insights that can be used to make informed decisions.

Supervisory Control and Data Acquisition (SCADA) systems are designed to provide a comprehensive, easily accessible overview of the progress of any given process in real-time. By using SCADA systems, details such as current status, warnings, alarms, and other relevant information are available instantly and accurately. This provides businesses with a reliable way to monitor and control their processes from remote locations without interruption or delay. This helps to streamline certain processes and greatly improves efficiency, allowing businesses to get more done in less time and reduce their reliance on manual labor. By automating these processes, businesses can save time and money while also improving the quality of their work. SCADA can be used for predictive maintenance tasks to help reduce unexpected downtime, optimize the efficiency of operations, and ultimately lead to improved outcomes throughout the organization. This can result in cost savings and improved customer satisfaction as a result of better overall operations. When selecting SCADA (Supervisory Control and Data Acquisition) software, certain features are important to consider to get the best value for your investment. Features such as scalability, performance, stability, reliability, data security, and integration with other systems should be evaluated when making a decision. Additionally, features such as detailed reporting capabilities and ease of use should also be taken into account when selecting the best SCADA software. In addition to allowing for remote access, alarm management, and data logging capabilities, these SCADA Systems can also generate reports for more detailed analysis on demand. This provides a powerful set of tools that streamlines the workflow process and increases productivity. By incorporating the latest cutting-edge features, a Supervisory Control and Data Acquisition (SCADA) system can become substantially more effective and efficient in monitoring, controlling, and managing all aspects of an industrial process. These features include real-time data collection, remote device control, alarm management, graphical user interfaces, data logging capabilities, and automated reporting tools.

Furthermore, this system should be designed to be compatible with the Windows operating system to guarantee a smooth and easy access from any device that runs it. This compatibility would enable users to have access to their data from any device, ensuring maximum productivity and convenience. This user-friendly system will enable users to access it with ease and convenience, regardless of their device type or platform. It is designed to provide maximum usability without any hassle or difficulty, allowing users to quickly and easily utilize the system for their needs. If you're looking for a cost-effective solution to take advantage of the power of SCADA technologies, then free automation software can be an excellent option for you. It provides a great way to get started without having to invest large amounts of money upfront, and it can provide access to all the features that are available with more expensive solutions. SCADA technology has revolutionized the way that industries and businesses manage their resources, and it permits even those with limited resources to take full advantage of its benefits. With SCADA technology, businesses can reduce their costs and improve efficiency by remotely monitoring and controlling their systems in real-time, thus eliminating the need for manual operation. SCADA technology also provides data-driven insights that can help companies make decisions quickly and accurately.

Windows, Linux, .NET HMI, Web HMI, Real-Time and Historical Trending, Alarm Notifications and Logging, Log Data to an open Database.