The Future of Work Robots Automation in Industry

Key Highlights

- The surge of robotic process automation (RPA) is revolutionizing business process automation, allowing companies to enhance efficiency across diverse sectors.

- Automation technology excels at streamlining tedious and repetitive duties, minimizing human error while significantly increasing productivity.

- Innovations like industrial robots and collaborative robots (cobots) are reshaping manufacturing and material handling processes with unmatched precision.

- The integration of artificial intelligence in automation software enables dynamic handling of both complex and virtual tasks.

- Embracing automation opens doors to new opportunities, albeit requiring shifts in workforce skill sets to keep pace with advanced systems.

Introduction

The rise of automation technology, industrial robots, and artificial intelligence is changing the way people in many industries work. In the past, automation was used for small, repetitive tasks. Now, it is found everywhere, not just in one type of work. It helps finish both simple and complex jobs in a way that is quick and exact. Robots used to need a person to control them. Today, they can do much of the work on their own. These tools are now used to change how we work, especially in fields like manufacturing. They help people try new ways to get work done. It is important to know about the potential and uses of these tools. That way, we can get the most out of automation technology, industrial robots, and artificial intelligence.

Understanding Robots Automation: Key Concepts Explained

Understanding Robots and Automation in Modern Industry

Automation and robotic process automation (RPA) have changed a lot over time. These tools help the industry work better by speeding up tasks and making fewer mistakes. You can now count on more steady work in making products or handling online tasks because of automation software. This has made it easy to do the same jobs over and over with great results.

Today, process automation is about more than saving money. It helps businesses trust their work both in the real world and online. When you mix robotics with automation, companies can create better ways of working. They need fewer people to step in and have a chance to rethink how they do business. This really helps them stay in the game in a tough world market by cutting down on human intervention and keeping things running well.

Defining Robotics: Key Concepts and Technologies

Robotics is where industrial robotics, computer science, and engineering meet. It is all about making machines that help people work faster and better. Robots are mostly known as programmable machines. They depend on many kinds of technology to work. These machines can be run by people, control themselves a little, or be fully on their own.

The main parts of robots are sensors and actuators. The sensors act like the eyes and ears of the robot. Actuators help them move, just like muscles do. There are control systems that help them make decisions. These parts help robots change what they do to match their surroundings. They can do some jobs quickly that need human intervention when people do them.

While software robots are big in online tasks, physical robots are important in real jobs like healthcare, making things, and moving products. The physical robots lift and put pieces together, weld things in the right place, and check on things for good quality, even when human workers might miss problems. These programmable machines are a link between new technology and useful work that helps us every day.

Exploring Industrial Automation Systems

Industrial automation helps industries work in new ways by using the latest automation technology. You can get more done with less effort and time. This makes the job much more smooth and helps the business be more productive every year.

In the world of industry, automation can be used for many physical processes like CNC machines. There is also robot automation that can work day and night with no need for a break. These systems be set up to help reduce human error and keep up a steady flow of work without any big breaks.

You will find different types of automation, from those that do just one thing to others that you can change for many tasks. People use them in different business process settings. If you mix them with business process automation, work goes on without trouble in factories, moving goods, and in other places, too. From handling and moving things (material handling) to looking for mistakes, automation systems help replace slow manual jobs with faster and smarter moves. This keeps the whole area growing and changing for the better.

Types of Robots Used Across Industries

Robots are found in almost every big industry now. Industrial robots lead the way in things like manufacturing. They do jobs like putting things together, welding, and handling materials. They do all this with great accuracy.

On the other hand, collaborative robots, sometimes called cobots, are made to work with people. These cobots help industries use robot automation more easily. They use automation software and can even work right with human workers. These robots help bring together human judgment and robotic skills, and this connection keeps getting better all the time.

Collaborative Robots (Cobots) and Their Applications

Collaborative robots, also called cobots, are made to work with people, not take their jobs. These programmable machines help make people more productive in the workplace. They are used for different jobs, like material handling and work on an assembly line. Cobots are built to fit right into the process that companies already use.

These collaborative robots use machine learning to change how they work, so they can adjust to new things and do complex tasks more accurately. In industries like manufacturing and customer service, cobots show how automation technology can lower human error and help things run better. They give people a new way to get work done as they work side by side with these advanced tools.

Autonomous Mobile Robots in Manufacturing

In manufacturing, autonomous mobile robots (AMRs) are changing the way materials move within a factory. These robots use computer vision and image recognition to improve material handling so tasks in fast-paced production areas get done with ease.

Many leaders in the industry use AMRs for jobs like sorting goods and assembly logistics. AMRs are different from regular industrial robots because the AMRs can move around and make decisions on their own. These machines use smart coordination and need little human intervention. The robots work in a safe and steady way while following important safety rules.

AMRs use automation tools to take on tough jobs that are hard for people to do by hand. Their speed and smart abilities help raise the standard for robots in today’s factories. The use of AMRs in modern manufacturing shows how quickly the industry can change and grow.

Forms of Industrial Automation

Industrial automation covers many solutions. Some systems are made for one task while others are flexible to meet changing needs. These forms of automation use automation technology to do regular jobs with more accuracy.

As more businesses use it, they control machines, watch over processes, and improve settings with automation. It does not matter if they work with one task or use it across many parts of the business. Automation helps make work faster and better, so what comes out matches business goals as they change over time.

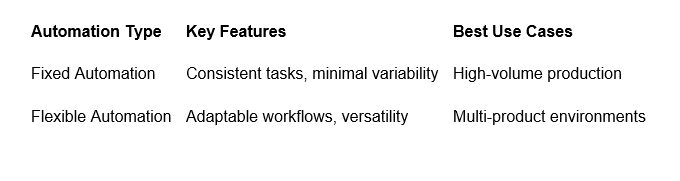

Fixed vs. Flexible Automation Explained

Fixed automation and flexible automation are not the same. Each one works in its own way and fits different types of automation jobs. Fixed automation is great at handling tasks that do not change. It is used in places where you make the same thing again and again, such as making car parts on a line. This type is good for consistency and speed when the task is set.

Flexible automation is different. It uses programmable machines that make it easy to change what you do at any time. This way, people can make many products or change the setup based on what they need. It is good for when new jobs come up, or there are many product changes. It can shift to a new task without stopping everything else.

By using software solutions in these flexible systems, people in the industry get more choices to control how they work. This lets them make into their own set-up. It helps them go from one job to the next and do more in less time with fewer problems. So, the right software solutions and programmable machines help people get the most value, no matter the task.

Role of Artificial Intelligence in Automation

Artificial intelligence (AI) is changing the way we do things by making systems smarter and able to handle new tasks. Because of machine learning, AI helps intelligent process automation work better in many places. This is true on factory floors, with computers, and in places that use a lot of data.

Using things like process mining, AI finds the weak spots and tries to do the job better. With the help of this technology, software can use advanced AI to cut down on human error. Teams get more accurate results because the workflows can match up with what is really happening.

AI now sits next to automation software in many settings, from online spaces to work in the real world. Health care, moving systems like trucks and warehouses, and financial services all see big changes because of AI-driven systems. The improvements from process automation help companies and people do more with less effort.

Impact of Robots and Automation on the Workforce

The use of robotics is changing how human work and technology come together. Process automation helps to get work done faster and more easily. But, it can also lead to job loss since some manual jobs are now done by machines instead of people.

At the same time, automation software is making new jobs for people who can program, watch over, and help run robots. When companies go through these changes, it is good to stay flexible and keep learning at work. This way, the new technology will work side-by-side with human skills.

Evolving Job Roles and Required Skill Sets

With digital transformation changing the workplace fast, jobs also change because of software automation and more rpa implementations. The people who work need to learn new skills to do well in these places where automation is key. Here are some important things you need:

- You have to be good at computer science and machine learning to program automated systems.

- It is important to use human judgment to check on robot decisions, especially when things are not simple.

- You need to know how to use rpa tools to help with business process automation.

- You also need to change the way of working and work well with robots.

If people get these skills, they can stay important in businesses that move quickly because of robotic and process automation. This helps them keep up with changes in business process, machine learning, and computer science while using software automation in the workplace.

Addressing Concerns: Job Displacement and Opportunities

Job displacement is a big worry right now because of more machines and smart tech. There are some problems, but also some chances with it. Machines can do some tasks faster, so companies do not need as many people doing simple jobs. But now, these companies need people who know how to set up and watch over these systems. If you are able to work with tech, you can get good jobs here.

With business process automation, routine jobs get done by machines. This is true for many jobs, especially in places like financial services. But people in this field learn new things, often going through retraining programs. This use of process automation helps workers. It can lower stress, and workers might get to move into roles that use their minds more and offer new chances.

It is key to keep human input along with these changes. With both tech and people working together, we can keep up with new ideas in the workplace. This helps companies and people stay strong for years to come.

The Future Trends Shaping Robotics and Automation

Emerging robotics trends are bringing big changes to many industries. Right now, new automation software and emerging technologies are helping drive this forward. Things like collaborative robots, AI working with machines, and even virtual spaces are leading the way.

Industries now look to robots, automation software, and the use of automation to take on harder problems. These changes bring better ways to work and a chance to do things in a more green way. The new ideas and tools are set to shape the U.S. market in the years to come.

Emerging Technologies and Their Potential in U.S. Industries

Emerging technologies are changing many U.S. industries. New things like rpa bots help make workflows easier, speed up accountability, and make quality better. They improve the business process in many ways and also help companies build better services around the customer. These changes are hard to ignore.

In manufacturing, workers use automated tools to help move products through the supply chain. Robotic automation works great even in virtual environments. Healthcare has also grown with software robots that help doctors during surgery or help in finding illnesses with high precision.

As more companies start using automation, these technologies help businesses to adapt quickly and meet new industry needs. The future looks good for the growth of automation.

Conclusion

In the end, robots and new tools are changing the way we work. There are big changes happening in many areas. It is important to know what robotics can do and how automation will change job roles. These changes are not just about machines doing people’s jobs. They also let people learn new skills and help work change for the better. If you use these changes right, you can work faster and bring in new ideas. This will help your business grow in the future. If you want to do well in this world that moves so fast, you should look at the newest trends and tools shaping the field. If you want to keep up and help your business, talk to us for advice about how automation can help you or your organization.

Frequently Asked Questions

How are robots and automation changing workplaces in the U.S.?

Robots help make work faster and smoother by using robotic process automation. They handle repetitive tasks with a high level of accuracy. In factories, industrial robots help make different steps in the process better and simpler. Automation technology tools also help make business process jobs easier and less time-consuming. All these things together help speed up digital transformation and are changing how the workplace looks in the U.S.

Can automation exist without robotics?

Yes, you do not always need physical robots for automation. With automation software, you can use process automation or business process automation for tasks as virtual tasks. You do not need any paper forms for this. For example, you can use this software for things like data analysis and system scheduling. These can work with very little human intervention.

.

Are robots replacing human workers entirely?

No, robots be there to help human workers. They do things that are repetitive, unsafe, or need high precision. Collaborative robots work with people. They allow human judgment and decision-making to still be important. Automation software can help workers, but it does not fully replace them. There are still roles that need people who have adaptability and creativity.

What industries benefit most from automation and robotics?

Industries such as financial services use automation to handle the same tasks again and again. In manufacturing, companies use industrial automation to help make things faster and better. Fields like customer service and logistics do well by mixing business process automation with new robotics technology.

What skills will be essential for future jobs with automation?

Many future jobs will need people with skills in computer science, machine learning, and software solutions. It is important to know how to use rpa tools and have experience with image recognition. These can help you adapt well in industries that use automation. Workers also need to solve problems and think in new ways.