Discover How Robots Automation is Transforming Industries

Key Highlights

- Robotic process automation (RPA) and automation software help businesses work faster by taking care of repetitive tasks. This means there is much less need for people to get involved in these jobs.

- Industrial robots and collaborative robots are changing the way we do manufacturing and material handling. They help to improve how well things get done and also make the workplace safer.

- Automation technology is used for both virtual and physical processes. You can see it being used in many industries like financial services and healthcare.

- Artificial intelligence and machine learning are making intelligent process automation better. Now, robots can do more complex jobs that need a lot of data to be right.

- When you bring robotics and process automation together, it is changing many industries. This way, companies get the most out of their work and lower the chance of human error.

Introduction

Robotic automation is changing the way industries work. It helps push forward digital transformation, and it makes the way things run better. With automation technology, tasks that used to need people can now be handled by machines. This shift is large, and it affects how businesses run every day. You can see the change in places like manufacturing, healthcare, and financial services. These new ways bring both speed and accuracy. The use of programmable machines and systems driven by artificial intelligence helps a lot too. Robotic automation is no longer just something for the future. It is real and important now. In this blog, you will read about the way robots and automation are helping many types of businesses. It shows how these changes are setting up a fast-moving, exciting world shaped by technology.

Understanding Robots Automation: Key Concepts Explained

Understanding Robots and Automation

Robot automation is at the heart of new industrial and tech growth. It covers programmable machines that do tasks fast and with very little help from people. These robots can be simple ones on a line or smart systems that use artificial intelligence.

Automation comes in a few forms. Software automation handles virtual tasks, and industrial automation focuses on physical processes. Both show how robot automation and artificial intelligence can make things work better. They turn human tasks into simple steps that machines can repeat the same way each time. Keep reading if you want to know more about the main ideas behind robotics, automation, and how programmable machines help with both physical processes and virtual tasks.

Defining Robots: What Makes a Machine a Robot?

Robots are special programmable machines. They are made to work in the physical world and can finish tasks with or without help from humans. Deep down, they be powered by computer science ideas, like machine learning and artificial intelligence. Some robots are called physical robots. These machines use sensors to see what is around them, use actuators to get a job done, and have control systems that help them follow orders smoothly.

What makes a robot unique is how it can change what it does. Unlike a simple machine that works on only one job, robots can be reprogrammed to do different things. This is a big reason why industrial robotics is so useful. Industrial robots, for example, are great at lifting, putting things together, and welding on production lines.

These machines are able to work on their own or with human intervention. Today’s world of modern robotics is growing fast with artificial intelligence. This new mix helps robots learn and handle real-world problems on their own. Because of this, they are now very useful not only for material handling but also in customer service and many other jobs.

Automation Explained: From Simple Tasks to Complex Systems

Automation is about ways to cut down or take away the need for people to do the same tasks over and over. This is done by using the right automation software or machines. For example, software solutions such as robotic process automation act like people in the digital space. They help make work go smoother and need less help from people.

Process automation can be used for lots of things. It works with simple jobs and can also handle hard work, like moving data, talking to customers, or running controls on a production line. Now, with artificial intelligence, smart systems let you make fast choices in real time. In places that need things done right and the same way each time, automation software is a big help to all of us.

Also, automation isn't just for easy things. It is not only about basic tools, but goes up to big jobs like manufacturing where they use industrial automation to run physical processes. These can include putting products together or checking their quality. Because automation can work in both computer programs and in real-world jobs, it fills gaps, boosts how much you can get done, and helps make sure every job is done right every time.

Key Differences and Overlaps Between Robotics and Automation

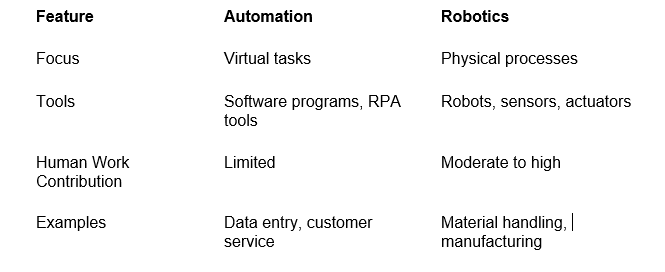

While robotics and automation are connected, they are not the same thing. Automation technology uses different systems and software, like business process automation, to handle repetitive tasks with speed and accuracy. Robotics, though, is about making physical robots. These robots are created to do jobs in the real, physical world.

The two come together in some areas. For example, you see this in robot-assisted industrial automation. It helps boost efficiency and bring in new ways to get work done. Robotic process automation brings together software robots and hardware to make things better in both factories and service businesses. Here, let's look at their main technologies and see how they match up.

Comparing Core Technologies and Processes

The way we use robotics and automation depends on what they do. Robotics mainly deals with physical processes. Automation software is mostly used for digital, or virtual tasks. With robotics, there are programmable machines that work on jobs where something needs to be moved or handled. Automation uses RPA tools and computer software to finish tasks that people usually do on a screen, making things go smoother.

Although they are different, both robotics and automation software can work well together. When you use them both in things like industrial automation, they help make jobs very exact. This teamwork lets robots and computer software do more work and helps people have less to do.

How Robotics and Automation Work Together in Industry

Industries now use robot automation and automation technology to be much more efficient. Collaborative robots, also called cobots, help a lot in industrial automation. They work on jobs like assembly together with people. This setup keeps the work safe and productive in places where people and robots work side by side.

In manufacturing, software robots look after the virtual side of the work, while physical robots help with material handling. These robots handle jobs like loading and unloading things, making sure that the process from start to finish is smooth. With this teamwork, there are fewer human mistakes, and companies get to use their resources better.

When you bring in software solutions, it lets robotic processes talk easily with a company’s other systems. For instance, if you use automated quality checks and match them with data analysis, you get feedback faster and products improve. These fresh systems show how robotics and automation work closely together to change how industries do things.

Types of Robots Used in Industrial Automation

Industrial automation uses different types of robots for many jobs. Industrial robots handle big jobs with many steps, like welding or putting things together. They help to do repetitive tasks faster and better, so you get more done and make fewer mistakes.

Automation software works with these robots. It helps to do complex work in different places or industries. The software can be used in programmable machines as well as with highly advanced collaborative robots. These systems let companies work better and change as needed.

You can use them when there are new demands or problems on the job.

Below, we look at the two main types of robots used in industry today.

Industrial Robots: Arms, Mobile Units, and Cobots

Industrial robots are very important in factories. These robots use programmable machines to do things such as material handling and welding. Robotic arms are common on assembly lines. They are strong and work with great precision.

There are also mobile units. These industrial robots move parts and other items across the factory. The main job of these robots is to do repetitive tasks. This gives people more time to do jobs that need new ideas and planning.

Collaborative robots, also called cobots, work right next to people. They bring more flexibility and can be used in more ways. Unlike older industrial robots, cobots are made to help people and work together with them. This makes jobs like packaging and quality control smooth and easy. The different kinds of industrial robots, such as those for repetitive tasks and collaborative robots, show that there are many ways to use automation in factories for different industry needs.

Service and Collaborative Robots in Modern Workplaces

Service robots and cobots are changing how people work at different jobs. These new machines are not the same as old industrial robots. These are programmable machines made for places where people and customers interact.

- Service Robots: Work in online spaces to help with customer service jobs. They give people up-to-date information.

- Collaborative Robots (Cobots): Stay close to human workers. Together, they get safer and better results at work.

- Adaptability: Cobots use machine learning to change as tasks change. This means you do not always have to program them again.

- Versatility: They can move between jobs like data analysis or material handling. They do what the company needs most.

Bringing in automation technology helps these robots and people work better together. These robots add to human judgment and skill. With the use of machine learning and collaborative robots, workplaces now have new ways to get more done all around the world.

Impact of Robotics Automation on Major Industries in the U.S.

Robotic automation is changing the way many big industries in the U.S. do their work. This change helps make things faster and easier. Companies in financial services use business process automation to handle many repetitive tasks. When they use RPA implementations, they save time and cut down on mistakes.

In manufacturing, robots step in to take care of jobs that are risky or unsafe. This helps keep people out of danger. In healthcare, process automation and intelligent process automation help give more accurate results. When hospitals and clinics use artificial intelligence, they can do their jobs better.

So, different industries like manufacturing and healthcare see big benefits. They get better results, cut costs, and work faster with the help of robotic automation, business process automation, and artificial intelligence. Let’s take a closer look at how this works in healthcare and manufacturing.

Manufacturing: Revolutionizing Production Lines

Manufacturing industries have changed a lot in recent years because of industrial automation. Robots now do many repetitive tasks like assembly, welding, and sorting materials. They work with great speed and accuracy, which helps to cut down on human mistakes.

The addition of robotic systems along with process mining means that operations can run well. It looks at different steps and helps find the best way to get things done. Programmable machines are also used for more than one job. This gives the production lines more flexibility and lets them handle different types of products.

Also, collaborative robots make places safer. They can work side by side with people in the same space. This teamwork shows how manufacturing is growing and getting better by using new technology.

Healthcare: Enhancing Precision and Patient Care

The healthcare field gets a lot of help from new artificial intelligence and robotic automation technology. Robots with computer vision are able to see and understand medical images. This lets them help doctors with image recognition and makes diagnoses quicker and more accurate. When surgery is done with the help of robots, it can be safer because of their high level of accuracy.

Robotic automation also helps doctors and staff give out medicine and handle their work better. Hospitals use process automation, like RPA tools, to take care of routine tasks. This gives their workers more time to be with patients and provide care.

With these changes, from making diagnoses using images to using artificial intelligence and RPA tools for process automation, healthcare is seeing better results and running more smoothly. The healthcare world is now trying out some of the most advanced ideas and using them every day.

Conclusion

Robotic automation is more than just a trend. It is changing many industries and shaping new ways to work. When people understand how robotics and automation work together, they can use both to help their business. This can make work better and faster, and help people think of new ideas.

Many industries like manufacturing and healthcare now use automated solutions. You will see that robots can help save costs, make people more productive, and give better results. Adopting this change is needed if you want to keep up in the fast market today. If you want to know how robotic automation can help your business, feel free to ask for a free consultation. We can talk about the next steps you can take toward using more automation in your future.

Frequently Asked Questions

..

Are robots taking over human jobs?

Robots are not taking the place of all human work. Instead, they are changing how people work. The Harvard Business Review says that robots do tasks that are boring or risky. This lets people do the things that need creative ideas or choices, like programming, maintenance, and supervising the work.

What are the main benefits of robotic automation for businesses?

Robotic automation can help in many ways. It can lower costs. It can help people get more done at work. It can also help be sure there are fewer mistakes the people make. When you use automation software and RPA bots, your business can do tasks faster. These tools make it simple to control the work that must be done. With robotic automation, people can grow their work without needing more resources. It is a good choice for any company that wants to work smarter and not just harder.

Can small businesses afford to implement automation?

Yes, automation is now easier for small businesses to use. RPA software and other software solutions help small companies to automate some work. These tools help people do jobs faster and improve how the business runs. You do not need to spend a lot of money when you start. There are tools that you can change to fit your needs. You can add the automation step by step, so it is not hard or too much for your team.

How secure is data in automated robotic systems?

Data security in robotic systems depends on strong RPA implementations and good software automation. With little human intervention, bots stick to clear rules. This helps cut down on mistakes. If everything is set up the right way, these systems are not as easy to break into.

What are the future trends in robotics automation?

Some new trends in robotics are all about intelligent process automation. This comes from using machine learning. Now, you see robots that can learn from what happens around them. You will also notice digital transformation in every industry because of this.

In the future, there will be more collaborative robots. These robots will work with people. There will also be progress in healthcare when it comes to robots and AI working as one.