Understanding Robots Automation A Beginner's Guide

Key Highlights

- Robotic process automation (RPA) is revolutionizing businesses by automating repetitive tasks, enhancing efficiency, and freeing up human workers.

- Automation software is integral to streamlining virtual tasks, enabling digital transformation and smarter workflows.

- Industrial robots are transforming manufacturing with their ability to handle material and physical processes, improving productivity.

- Collaborative robots, or cobots, work alongside humans, combining automation with human judgment for better performance.

- Business process automation drives cost savings and security while scaling operations seamlessly.

Introduction

Robot automation and process automation are changing the way we work in different industries today. With the help of artificial intelligence and other new tools, these systems can do many tasks that people used to do. They help businesses by taking over things like data entry and physical jobs on a factory line. This way, they help make the work faster, get rid of mistakes, and make everything more accurate. Sometimes, you will see a collaborative robot working next to people in a factory. Other times, there will be software bots sitting at a desk, handling digital work. The use of robot automation and process automation is showing up everywhere, from offices to big factories. These changes also mean that there is less need for human intervention in simple jobs. But, what do robots and automation actually mean, and how do they work together?

A Simple Guide to Robots Automation Explained

Defining Robots and Automation

Robots and automation are changing the way businesses work. They help companies do tasks faster and with fewer mistakes. Robots are machines that act in the physical world. They use sensors and follow commands set by people. Automation is different. It uses tools like robotic process automation to do repetitive tasks. These tasks can be in the physical world or for virtual tasks on a computer. Automation helps make business workflows better.

When we talk about robotic process automation and automation technology, there is a difference. Robots are machines that people can program. They can work on their own or sometimes need some human intervention. Process automation uses automation software and smart systems to improve virtual tasks. When you use both robotics and automation together, companies see better precision, higher productivity, and safer workplaces with less human error.

What Is a Robot?

Robots are programmable machines. They are made to do certain tasks. Many times, these jobs need some physical work. These physical robots come from the world of industrial robotics and computer science. They help with material handling, putting things together, and other jobs in many industries. These machines use sensors and parts called actuators. This helps them follow exact instructions in the real world.

The word "robotics" is used for these kinds of machines. They can be simple industrial robots that you find in factories. Or, they can be new collaborative robots that work side by side with people. What makes robots special is their power to do what they are told. Some, with advanced AI, can even make decisions. This use of technology is changing the way work gets done.

Industrial robotics is very important for handling materials today. These robots make work fast and very accurate. For example, they do loading, unloading, and even harder work like welding in factories. By taking on hard jobs, robots give people more time for things like management, watching how things are going, and making plans.

What Is Automation?

Automation means using technologies like automation software to make tasks happen faster and better than how people used to do them by hand. Process automation often uses software robots to take care of repetitive virtual tasks. In industrial automation, machines take over physical processes inside factories and other businesses. Both process automation and industrial automation help cut down on human intervention and mistakes.

When it comes to business process tasks, software automation can help you with things like entering data, testing systems, and planning schedules. Robotic process automation copies what people do on computers to make work smoother. Intelligent process automation uses AI and machine learning to help with making choices and moving things along even better.

Industrial automation uses machines and robots to do jobs like welding or putting parts together. These systems matter because they keep people safe, help businesses make more products, and make sure the results stay the same every time. At the same time, human workers get to spend their time on work that gives more value to the company.

Key Differences Between Robots and Automation

Robots and automation are related, but they are not the same thing. Robots are programmable machines. They work in the physical world. You can use them to lift items, put things together, or move objects. Automation is about using technology, such as software tools and other systems, to make tasks easier. This helps improve how people do their work, whether it is in the real world or online.

Robotic automation uses machine learning to make better decisions. Software automation works in online places so it can handle repetitive tasks. Both robotic automation and software automation work well together. They help people be more efficient in both the physical world and on computers.

Distinguishing Features of Robots

Robots are easy to spot because they can do physical processes in the real, physical world. These programmable machines use things like industrial robots and collaborative robots to do certain jobs well. You will see them a lot when it comes to material handling or on assembly lines.

One thing that makes them special is how they work with the physical world. They have sensors and other tools that copy how people use their judgment. For example, industrial robots are everywhere in factories doing repetitive tasks. Collaborative robots are built to work right next to people. With robot automation, they can work on their own or with some help from people.

Robots have changed the way physical work gets done with their precision and speed. No matter if it’s lifting heavy stuff or doing careful, detailed work, robots have taken over many tasks that people used to do. Now, businesses can get things done faster and more reliably because of them.

Unique Aspects of Automation

Automation is great for improving software-based work. It helps with digital transformation in the different types of industries. This includes business process automation and intelligent process automation. Both use automation software to help get smarter results.

Unlike robots, automation does not always use physical machines. Many software solutions, like RPA bots, work in virtual settings. They do repetitive tasks such as meeting scheduling or managing data. You can use them to cut down on human error and make governance better and easier to monitor.

This type of process automation gives a business the ability to scale up and keeps things secure. That makes it important to companies who want to make their business process simple and keep costs as low as possible. When you go with systems like these, you let human work and technology come together for better efficiency.

How Robots and Automation Work Together

Robots and automation work well together in many industries today. The use of robots to help with process automation shows how real work and smart software can come together. This can make things run better and use less human intervention.

When businesses use automation software to help make decisions and have robots do the hands-on jobs, industries like manufacturing and logistics get more done. This teamwork is a good example of how technology makes work go smoother and lets people focus on more important tasks.

Integration in Modern Industries

Industries now use more automation technology and robotic solutions to get better results. In financial services, robotic process automation helps with jobs like account checks. Industrial automation helps boost how much work production lines can do.

RPA implementations let businesses use process automation for many tasks. This means they do not need much human intervention. The manufacturing sectors gain a lot from automated material handling systems. These systems help to increase how much work gets done and keep people safe from harm.

When companies start using intelligent process automation and the use of robots together, they work faster. This also gives them new ways to scale and grow their business.

Real-World Examples of Collaboration

The way robots and automation work together shows up in many real-life ways:

- Healthcare: Robots help with surgeries and take care of repetitive tasks, such as giving out medicine.

- Manufacturing: Industrial robots do welding, put things together, and pack items without a problem.

- Customer Service: Automation software helps chatbots talk to people, making customer service better.

- Logistics: Collaborative robots help sort and move things in warehouses and places where goods are handled.

- Agriculture: Robots can harvest and watch over crops, so there is less need for people to do those jobs.

These real examples show how much you can do by bringing robotics and automation solutions together.

Types of Robots Used in Automation

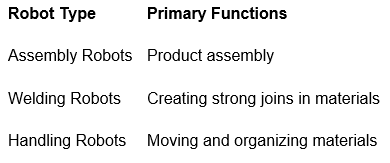

There are many kinds of robots that help different industries with strong automation. In factories, industrial robots be the main type to use. They help with material handling and keep assembly lines moving fast.

Collaborative robots, also known as cobots, work side by side with people. These robots use computer vision and image recognition. That lets them mix human judgment with strong automation power. Cobots help with complex tasks in the physical world. People use them for jobs like customer service and detailed work.

Industrial Robots

Industrial robots are useful in material handling, putting things together, and doing the same work many times. These machines can be programmed and are a big part of industrial robotics. They help make things faster in factories, and you do not need a lot of human intervention.

These robots do a good job in quality work and keep the result the same each time. Because they be programmable machines, they do simple repetitive tasks like putting things on pallets and packaging. Human workers are there to oversee what happens, keep things safe, and check on their work.

Service and Collaborative Robots

Service and collaborative robots help people work together better in many workplaces. Unlike industrial robots, service robots aim to help in customer service spaces. They use human judgment to make the customer experience better.

Collaborative robots use new tools like computer vision. This helps them do jobs with more flexibility. One example is image recognition. With this, these robots can work with a high level of accuracy in areas like retail and healthcare.

These solutions do more than just take over hard work. They also help people do their jobs in a safer and more efficient way. With these robots, people do not lose their own ideas or need to give up strategic thinking.

Benefits and Challenges of Robots Automation

The benefits of RPA bots and software robots are many. You can have lower costs and fewer human error mistakes. The workplace becomes a lot more efficient. These systems also help your business to grow and be more safe because they bring scalability and security.

But, there are some challenges, too. At first, the costs to start can be high. RPA implementations can be complex. Plus, human intervention is still needed. People need to step in to fix any problems that come up. This keeps the robots and automation technology working well together for the best results.

Advantages for Businesses and Workers

Robots and the use of automation come with a lot of benefits:

- The process automation in business lets work get done much faster.

- People see better precision in doing repetitive tasks, so there are fewer mistakes.

- When you have RPA tools, you save money. There is no need to have a big team for jobs that feel the same every day.

- Human workers can be safer, since they do not have to go into dangerous places as often.

- Robotic automation also helps every business process grow. It’s easy to adapt workflows and keep things running well.

These points show that robotic automation and business process automation have become a big part of building safe and productive places to work.

Common Obstacles and Solutions

Challenges like high upfront costs can stop many companies from using RPA software right away. Setting up automation still needs human intervention. People have to step in to fix problems when the system is being put in place.

RPA implementations also run into trouble when different automated systems cannot work well together. The answer is to invest in software solutions that help beat these problems with integration and make things run smoothly.

By using automation tools made for each industry, businesses can get past these early issues. They also gain confidence when starting with these new technologies.

Conclusion

Robots and automation are changing the way industries work. They help increase efficiency and bring new ideas. To keep up with this fast-changing area, you need to know the basic differences between robots and automation and see how they can work together. We saw that these tools can do a lot to make your work faster and smoother. But, they also bring some special problems that people must think about. When businesses stay up to date and find the right balance in using robots and automation, they can get the most benefits from both.

Using this technology is no longer just something popular; it is something you need to do to grow and keep your business alive in the future. If you want to learn more about robots and automation, you can reach out and ask for help. Find out how robotics automation can meet the needs of your industry.

Frequently Asked Questions

Can automation exist without robotics?

Yes, automation can be used without robots. Software automation helps with things like data entry and business process tasks. It works on virtual tasks without the need for physical robots. These systems work on their own in the digital world, so people do not have to step in as much.

Are robots taking over human jobs in the US?

Robots are now used for many repetitive tasks. But they do not do all human work. They help by doing hard jobs that take a lot of time. Humans are still needed to watch, manage, and tell the robots what to do. This way, people and robots work together.

What are the main industries using robots automation?

Industries such as manufacturing, financial services, and logistics use process automation a lot. Many companies use industrial robots for work like material handling. Business process automation makes it easier to do things like manage financial transactions. This shows how common robots and business process automation are in these fields.

How expensive is it to automate with robots?

Using robots for process automation comes with some costs. These costs are mostly for rpa implementations and software solutions. At first, you may need to spend a good amount of money. But intelligent process automation can help save money over time. It does this by making work faster and making business processes simple.

What skills are needed to work with robots and automation?

If you want to work with robots and automation, you need to know about computer science, machine learning, and robotics. You should also get to know different rpa tools. It is good to understand programming software and how automation technology works. These skills help you use automation the right way.