What are the 4 types of Scada

HMI SCADA systems are divided into 4 distinct generations based on their architecture

- The initial stage of SCADA (Supervisory Control & Data Acquisition) systems was known as 'monolithic SCADA' which marked the beginning of its use.

- 2nd generation distributed Supervisory Control and Data Acquisition (SCADA) systems are being widely used to effectively manage and monitor large scale industrial processes.

- The third generation of SCADA systems are connected through networks, enabling the sharing of data among multiple users and devices.

- Fourth generation SCADA, also known as the "Internet of Things" technology, is becoming more prominent in industries due to its capabilities. It allows for improved sensing and control with enhanced communication & integration of systems.

Monolithic SCADA

SCADA systems have evolved from stand-alone systems with limited connectivity to interconnected networks. Previously, redundant mainframe computers were installed to ensure system reliability. Communication protocols between devices were limited and lacked standardization until recently.

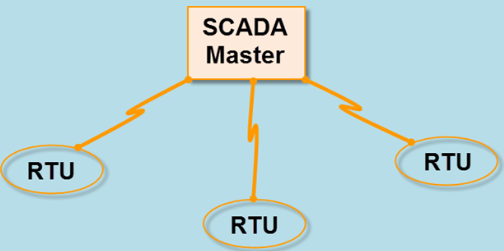

Distributed SCADA

The introduction of smaller MTU computers and networking revolutionized LANs, leading to improved operation efficiency and resource utilization. Individual control systems for each component enhanced real-time information exchange via a LAN, increasing system redundancy. Linking individual stations to the main SCADA through a WAN provided extended active periods. Second-generation SCADA systems benefited from networking, offering smaller and cost-effective solutions.

Networked SCADA

The evolution of distributed SCADA systems has been significant, especially with the introduction of standardized communication protocols. Standardized protocols have facilitated the use of commercial-off-the-shelf (COTS) components for designing SCADA networks. Moreover, the adoption of Wide Area Network (WAN) protocols like TCP/IP for communication between the master computer, HMI, RTUs, and field devices represents a significant advancement in this generation.

“Internet of things” SCADA

The latest SCADA systems utilize cloud computing and IoT technology for improved data analysis, faster response times, and efficient management. Cloud-based SCADA offers cost-effectiveness and scalability, but requires robust security measures. It provides convenient access to shared devices and network resources, and supports cloud bursting for data storage. SCADA systems can be configured as public, private, or hybrid networks.

- Public: Typically, companies own and manage public networks accessible by their SCADA systems, available through leased access. While cloud networks share similar architecture, their security measures differ significantly to ensure maximum protection. These networks may serve beyond SCADA systems and potentially offer unrelated internet-based services. Moreover, some cloud services are accessible to non-SCADA users at no cost.

- Private: Organizations have the option to internally host or outsource the management of their SCADA networks. This arrangement is tailored to each organization and can be extended to other systems within the same company. Private data centers are often expensive to operate due to space requirements, hardware installation, and the implementation of environmental management systems and maintenance.

3. Hybrid: Hybrid network services combine elements of both public and private arrangements. Designing and implementing such systems

require standardization of networks, protocols, and communication links. Multiple service providers can be combined to create a hybrid cloud

network, enabling practices like 'cloud bursting' where SCADA system providers pay for additional computing resources as needed.

Apart from the traditional cloud options, there are a few other variants in the market. These include community clouds, distributed clouds and multi cloud configurations - all of which can contribute to better operations and enhanced customer satisfaction.

SCADA systems are able to access the cloud in two different methods:

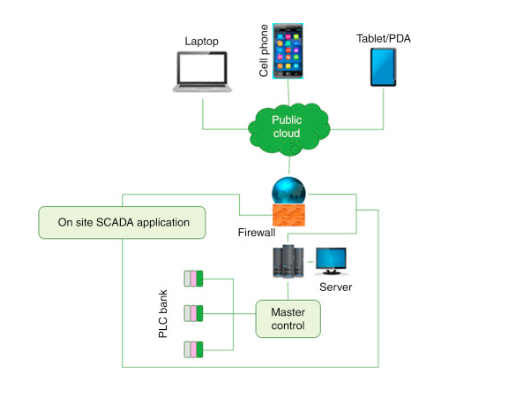

- On site application: SCADA systems run onsite and transmit real-time data over a direct connection to the cloud. The cloud can be accessed remotely, and the control units are connected to it as well. This allows for information sharing, circulation, and storage across a network.

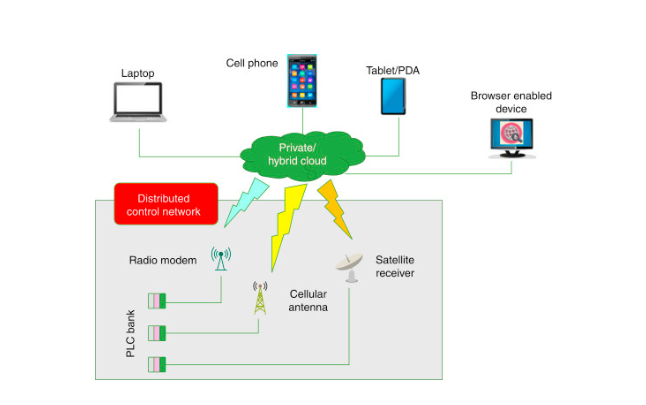

- Remote application: A SCADA system can be remotely controlled via the cloud, as long as it is being managed by an application from the cloud. All other storage and information sharing tasks are performed just like in regular cloud computing. Distributed configurations are a common term used to refer to this type of set-up. SCADA

Public cloud SCADA is a system where the SCADA runs onsite with data delivery taking place via the cloud. Additionally, PDA (Personal Digital Assistants) and PLC (Programmable Logic Controllers) are also part of this cloud formation.

Hybrid SCADA combines private and public cloud solutions, enabling remote access and monitoring through WAN connections. Cloud computing offers essential services with flexibility and scalability, while cost-effectiveness and automation tools simplify resource management.

1.Infrastructure as a service (IaaS)

2.Platform as a service (Paas)

3.Software as a service (SaaS).

Cloud-based SCADA systems offer flexibility and scalability, but require heightened security measures to protect against various threats. Traditional IT security measures are used, although SCADA systems have unique security requirements.