The Role of Automation PLC in Modern Manufacturing

Key Highlights

- A programmable logic controller (PLC) is an industrial computer at the heart of modern industrial automation. PLCs are essential for the control of machinery, executing tasks based on custom plc programming. Real-world examples include the use of programmable logic controllers in manufacturing assembly lines to coordinate conveyor belts and robotic arms, in water treatment facilities to monitor and control pumps and chemical dosing, and in building automation for regulating HVAC systems and lighting. Additionally, PLCs are employed in home automation to manage security systems and smart appliances, showcasing their versatility in both industrial and residential environments.

- PLCs are essential for the control of machinery, executing tasks based on custom plc programming.

- They perform crucial functions like logic operations, motion control, and real-time monitoring.

- Key components include a processing unit, memory, and input/output (I/O) modules for data acquisition.

- PLCs offer significant advantages over traditional systems, including greater reliability, flexibility, and cost-effectiveness.

- Choosing the right PLC involves assessing application needs, performance, and environmental conditions.

Introduction

Programmable logic controllers, or PLCs, are key to how things work in modern factories. They are strong computers that help run a lot of different machines and systems. The plc system is now a big part of industrial automation. It gives companies a way to control machines and other working parts in a simple and changeable way. In the past, factories used hard-wired relays, but now they use programmable logic instead. This switch helps factories be faster, more exact, and able to grow better.

Understanding PLCs in Automation

Programmable Logic Controller is a type of computer made to work well in tough places like factories. It uses programmable logic to run machines and control how things work. This makes it key to how industrial automation works today. If you ever think about how some assembly lines work so well, these control systems are often behind it.

The programmable logic controller gets signals from input devices and sensors connected to it. It then checks the data from these devices. After that, it sends commands to the machines based on its programmed rules. Because of this, industrial automation can be accurate and can happen the same way every time. Now, we will talk more about what programmable logic controllers are and how they started to be used in assembly lines.

Definition and Core Principles of PLCs

A programmable logic controller is an industrial computer made to control and watch equipment using a custom program. It is now the primary automation method that most industries use. These controllers have replaced old and hard-to-change circuits that used relays. The main job of a programmable logic controller is to run a set of instructions to manage a machine or a process.

The way a programmable logic controller works is by doing a scanning cycle all the time. First, it checks the input devices, like switches or other sensors. Then it runs the program that the user has made, using the input devices’ data to make choices. After that, it changes the status of output devices, such as valves or motors, based on those choices.

This cycle helps the system with process control by allowing quick changes and good management of the tasks done in factories. Because programmable logic makes it possible to take in input, follow instructions, and give output fast, it is a key tool for automation work.

Historical Development in Manufacturing

The PLC story starts in the late 1960s. General Motors wanted an electronic way to replace their hard-wired relay systems. Those old systems were hard to change and took a lot of time. Dick Morley is the person most people say invented the first PLC, called the Modicon 084.

The first PLCs helped a lot. They made it much easier to control industrial processes. For the first time, people could program machines for the work. These PLCs were big and cost a lot then. That is not the case now.

As time went on, the technology changed fast. Modern PLCs are small, strong, and not expensive. They can do more than what the old styles could. Now PLCs help with motion control, data tracking, and high-level talk between machines. They are used to do complex tasks in factory automation that people need today.

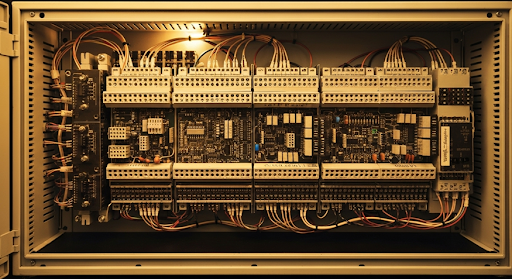

Main Components and Architecture of a PLC System

At the heart of a PLC system is an industrial computer made just for control work. This computer be built with some main parts that help to run industrial processes. The key parts are the central processing unit, the memory area, and the input/output modules.

These pieces work as one to help the PLC talk to machines and carry out commands with no trouble. Knowing how each part works will help you see what makes the PLC system powerful and flexible. The next parts will look closer at these main pieces and explain their jobs.

Processing Unit and Memory Structure

The Central Processing Unit (CPU) is the brain of the PLC. This microprocessor-based processing unit is responsible for executing the control program, performing data processing, making logical decisions, and managing communication with other devices. It continuously runs the program stored in the PLC's memory to manage the entire automation process.

The memory structure is another critical part of this industrial computer. PLCs typically use different types of memory for specific functions. The operating system and user program are stored in non-volatile memory, while temporary data and variables are held in volatile memory during program execution.

This division ensures that the core programming remains intact even if power is lost, while providing the necessary workspace for real-time calculations and operations.

| Memory Type | Function |

|---|---|

| ROM | Stores the PLC's operating system and firmware. |

| RAM | Temporarily stores data and variables during program execution. |

| EEPROM/Flash | Stores the user-created program and configuration data. |

Input/Output Modules and Interfaces

Input/Output (I/O) modules connect the PLC's processor to the machines and tools it controls. Input modules take signals from input devices like sensors, switches, and buttons. These signals tell the PLC what is going on with the equipment right now.

PLCs work with both digital and analog inputs. Digital inputs are simple. They show on or off, such as if a switch is open or closed. Analog inputs can have many values. For example, they might show a temperature reading or pressure level. These let the PLC have better control and adjust more things.

On the other hand, output modules send output signals from the PLC to output devices. These devices could be motors, lights, solenoids, or valves. The PLC tells them to turn on, turn off, or change what they are doing by sending output signals. This makes sure the PLC can fully control the process.

Power Supply and Communication Ports

A steady and strong power supply is important for the work of any PLC. The power supply takes the AC line voltage that you have and changes it into the DC voltage levels that the PLC needs. These are used by the inside parts, like the CPU and I/O modules. The power supply helps the whole system go without trouble and keeps it safe if the power changes.

The PLC also has communication ports. These let the PLC talk to and share data with other systems. The ports are used for communication protocols including Ethernet/IP and Modbus. By using them, the PLC can make a physical connection to HMIs, SCADA systems, and other controllers.

With these ports, you can set up the PLC, see its status, and put it on a bigger network. This is important for automation in today’s world. It helps you get centralized control and send data even to people or devices in remote locations.

Key Functions of PLCs in Industrial Automation

PLCs do a lot more than just turning things on or off. The main job is to run logic steps and keep things working in order. They also help with real-time checks, data acquisition, and motion control in a factory.

With these jobs, the PLC can watch over even the most advanced industrial automation and still be good at doing its work every time. One PLC can control many complex jobs with exact steps and do this for long periods without problems. It can look after single machines or even link up with big supervisory control systems across the plant. With all of this, PLCs are key in keeping control systems running in many kinds of factories. Next, we will talk more about these important functions.

Logic Operations and Sequencing

The main job of a PLC is to carry out logic steps. It uses programming languages, like ladder logic, to do this. Ladder logic looks much like old relay circuits used in electricity. You can make rules in the program for the PLC to follow. The program tells the controller what to do when certain inputs are met.

With this, you get the precise control of machinery. A PLC can do simple things, like turn something on or off. It can also take on complex tasks found in today’s factories. It does this by managing steps that have to happen in a special order. This is very important for work that needs steps to go just right.

For instance, on an assembly line, the PLC makes sure one thing is done before the next thing starts. When it follows instructions this way, you get better consistency, good quality, and safe work in automated processes.

Monitoring and Real-Time Control

PLCs work in real time. They keep checking inputs, run their program, and update outputs with almost no delay. This fast cycle time is key for good process control. It lets the system react right away to any changes in the area where it works. Can your system make choices in just milliseconds? A PLC can do this.

This real-time skill is very important for keeping things steady and running well in changing industrial processes. When you need to change a motor’s speed or hold a certain temperature, the PLC makes sure it happens right when it is needed.

PLCs also connect to a Human-Machine Interface (HMI). This link shows operators a visual view of the process, helping them watch the machine’s status, alarms, and data in real time. With this interface, it gets easier to watch over and step in to solve problems when needed.

Data Acquisition and Reporting

Modern PLCs do more than just help with control systems. They are a good tool for data acquisition, which means they can collect important data from the factory. This data is very useful for process control, keeping track of things, and reporting. Because of this, the PLC is not only there to run your work, but it also helps you get key business information.

When you use modern PLCs, they send the collected data to bigger systems like SCADA. These supervisory control systems save the data and look at it for a long time. With this information, engineers and managers can find patterns, help make work flow better, and plan for needed upkeep before things break. This makes the whole plant run better and cuts downtime.

PLCs get many kinds of data that are needed for businesses to know what is really happening. They can report on things like:

- Machine cycle times and counts

- Sensor readings like temperature and pressure

- Alarm conditions and fault occurrences

- Energy consumption and production output

Advantages of PLCs Over Traditional Control Systems

The spread of the plc system in industrial automation is mostly because it works better than old control systems, like hard-wired relays. In the past, when someone needed to change how the control systems worked, they had to redo all the wiring on big panels. This took up a lot of time and increased the chance for mistakes. PLCs changed all of this. With them, you do this work with software instead of wires.

The change to plc systems was good for reliability, flexibility, and scalability in the control systems used. PLCs also save money over time. Because of these reasons, people in industrial automation use plc systems more often now. The coming sections will talk more about these good points.

Reliability and Simplicity in Operation

One of the best things about PLCs is how reliable they are. Unlike mechanical relays, the PLC is solid and has no moving parts that might break. This means they last longer and be able to run for many years without failing. This is very important in big industrial areas where machines must keep working.

PLCs can also handle tough environments. They do well in places with very high or low temperatures, a lot of shaking, and electrical noise. Because of this, they keep working well, so there is less downtime. That is really important in any job that is making things.

PLCs are easier to operate than the older control systems. If something is wrong, it is much quicker for people to find the problem. Technicians can use programming software to see what is not working without following a lot of wires by hand. This makes fixing problems simpler and faster. It helps get things back up and running right away.

Flexibility and Scalability for Future Growth

Flexibility is one of the most important things about using modern PLCs. If you need to change how things work, you do not have to rewire the control panel. You can just reprogram the PLC system to fit the new way you want things done. This makes it faster and easier to make changes, so you save time and resources.

Modern PLCs are also good because they can get bigger and better as you need. This is called scalability. Many PLCs, especially the ones that are modular, are built so you can add more input and output modules. You can upgrade the CPU, or you can add more memory. This helps the PLC system handle larger or harder jobs as your business grows.

Because of this scalability, the money you spend on your first PLC system is protected. As your company gets bigger, the system can change with you. This gives you a solution that will last and keep working for all your control needs.

Cost-Effectiveness and Maintenance Efficiency

At first, you might think a PLC system costs more to set up than other control systems. But, over time, it saves you a lot of money. There is less wiring to deal with, and you can install it much faster. You spend less energy, too. All these things help you save more over the life of the system.

A big plus of using plc programming software with a plc system is how easy it is to keep things running. The software comes with tools that help you spot issues quickly. You can fix those problems fast. This means you do not have too much down time. When work does not stop, you save money and keep production moving.

Working with a plc system is much simpler than dealing with old relay panels. Relay panels need a lot of work and time to check or fix. PLCs are easier for people to maintain. There are not as many parts, so you do not need to keep a large stock of spares for repairs. This helps cut more costs from your control systems.

Choosing the Right PLC for Your Manufacturing Project

Choosing the right PLC is a big step for the success of your automation project. There are many types and models, so how do you pick the right one? It starts with looking closely at what your system really needs.

You have to look at things like the amount of inputs and outputs, how tough the job is, and how much power you need. The place where the PLC will run is also very important. Taking time to think about all these things helps you find the best PLC for what you want to do.

Assessing Application Requirements

The first thing you need to do when choosing a PLC is to know what your application needs. You must be sure about what you want the controller to do. For example, if the machine is simple, you might only need a micro PLC with a few I/O points. But if you are working with assembly lines or large industrial applications, you will need a bigger modular system that can handle thousands of I/O points.

Think about how complex the job is. Is the PLC going to do basic logic, or will it have to handle things like motion control, data logging, or fast counting? This will help you see what processing power and features you need.

You also need to look at communication needs. Will the PLC need to talk to an HMI, a SCADA system, or connect with other controllers in the network? If you figure this out at the start, you will get a PLC that has the right ports and protocols to fit easily with what you have now.

Sizing, Performance, and Environmental Factors

After you learn how the application works, you can start to think about the sizing and the overall performance of your PLC. Sizing means you figure out how many I/O points you need, and if they will be digital or analog. You should also look at the actual size of the controller. When it comes to performance, you check the speed of the CPU and how much memory there is. This needs to be enough so your program works right and does not slow down.

The place where the PLC will be used is also important, especially for remote locations and tough spots in factories. PLCs are made to stand up to harsh conditions, but some do better than others. You need to pick a PLC that can handle the temperature ranges and other things that come with its use.

You should think about these environmental factors:

- Operating Temperature Ranges: The PLC should be able to work in the heat or cold it will be in.

- Electrical Noise: The PLC needs to avoid problems from electrical noise, which often happens in industrial places.

- Vibration and Impact: Choose a PLC that is built to take on bumps or shaking, especially if it sits close to big machines.

PLC Programming Languages and Methods

A PLC gets its power from the program inside it. This program is made by using certain programming languages. Some of these programming languages are used more often than others. Ladder Logic and Function Block Diagrams are two of the most popular graphical languages you can use when doing PLC programming.

Every language gives a different way to show control logic. Which one you use often depends on what the programmer knows or why you need to use the PLC. You write these programs using PLC programming software. This programming software is usually made by the manufacturer, and will also have tools you can use for testing and fixing problems.

Ladder Logic, Function Block, and Other Languages

Ladder Logic (LD) is also called a Ladder Diagram. It is the most common language for PLC programming. This language is shown in a way that looks like the old relay control circuits. Many people, like electricians and technicians, find it easy to use because it looks like a control circuit.

Another well-known way to do this is called the Function Block Diagram (FBD). In this way, you can see your program as blocks. Each block does something, such as keeping time, counting, or doing math. The lines between these blocks show how the information moves from one block to another. This is very good for looking at how more complex actions happen.

Besides these, there are other programming languages you can use. One example is Structured Text (ST). This one looks like languages such as Pascal. People like to use it when they need to run complex math or work with big amounts of data.

Programming Process and Testing Steps

The process of plc programming starts when you know the control steps you need for a machine or process. The person who does the programming turns what is needed into a flow that the PLC can follow. He writes this logic with plc programming software and language.

After you write the first code, you need to test it well. This is one of the most important parts in the whole process. Programmers often use features in programming software that let them test how the logic works without putting it on the real PLC. This catches mistakes early and stops harm to the equipment.

In the last step, you send the program to the PLC. You test the system in a controlled area, before it goes live. These steps are common and help with a safe and good setup.

- Define the operational logic and sequence.

- Write the code using the appropriate plc programming software.

- Simulate and debug the program to identify and correct errors.

- Download to the PLC and perform real-world testing.

Conclusion

In short, Automation PLCs play a big role in modern manufacturing. They help make work faster and more flexible. When people know more about how PLCs work and what makes them better than old systems, companies can use them to make work simple, cut costs, and have fewer problems. As more industries grow and change, it is important to keep up and use new ways to improve your business. If you want to use PLCs in your place or need help, contact us for a free consultation and see how we can help you with automation.

Frequently Asked Questions

How do PLCs communicate with sensors and other automation devices?

A programmable logic controller connects through a physical connection at its input and output modules. It gets signals from input devices, such as sensors. It then sends output signals to things like actuators. For system-level uses, it uses industrial communication protocols like Ethernet/IP or Modbus. These help the programmable logic controller share data with HMIs and other controllers. People use programmable logic and these communication protocols to make sure all parts work well together.

What are typical troubleshooting challenges with PLC systems?

Some usual things that go wrong in an industrial automation PLC system are bad wiring to input devices or output devices, wrong program logic, problems with talking between parts, or a broken I/O module. The diagnostic tools in the programming software make it easy to find and fix these problems fast.

What emerging trends are shaping the future of PLC technology in manufacturing?

Future trends for modern PLCs show that there will be closer links with IIoT platforms. New designs will also focus more on stronger cybersecurity. Another big change is bringing edge computing in to help local process control become faster. These modern PLCs now have advanced safety PLC options. These tools are built right into normal controllers. This helps make many types of industrial applications work better.

Study PLCs/Automation More or Get Out While I Still Can?

Studying PLCs and automation is essential in today’s manufacturing landscape. As industries increasingly adopt smart technology, knowledge in this area enhances job security and opens new opportunities. Embrace learning now to stay competitive and relevant, as automation PLC skills are becoming indispensable for future career advancement.