Robots Automation: Transforming Industries with Technology

Key Highlights

- Robots automation is revolutionizing industries by streamlining complex processes using automation technology and artificial intelligence.

- Automation technology encompasses both physical robots and software robots, targeting business process automation and process automation.

- Robotic process automation (RPA) is reshaping digital workflows, freeing employees from repetitive tasks.

- Industrial automation and collaborative robots work together to improve productivity, quality, and workplace safety.

- Intelligent process automation and machine learning are fueling the digital transformation across manufacturing, healthcare, logistics, and agriculture.

- Despite efficiency gains, workforce evolution and human collaboration remain central to successful robots automation strategies.

Introduction

Modern industries are in the midst of a sweeping transformation thanks to robots automation, industrial automation, and artificial intelligence. These technologies are not just buzzwords—they’re the engines driving efficiency and productivity across countless sectors. By automating complex or repetitive tasks, companies can streamline operations and deliver faster, safer, and more reliable results. As robots automation makes its mark on everything from manufacturing to healthcare, understanding its role and potential is vital for any business aiming to thrive in today’s fast-changing world.

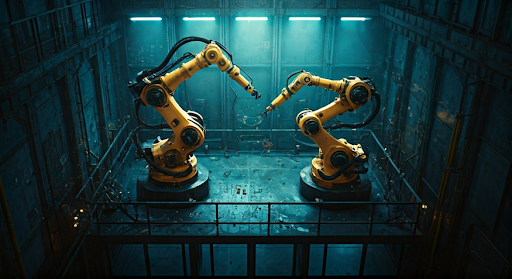

Understanding Robots Automation in Modern Industries

Robots automation is changing how businesses operate by seamlessly integrating automation technology and process automation into daily workflows. Today’s factories and offices rely on a mix of programmable machines and advanced software to handle tasks that once required significant human input.

This transformation goes beyond just replacing manual labor. It’s about reimagining how entire business processes run, making them faster, more accurate, and adaptable. Knowing the foundations and distinctions of these technologies is the first step to unlocking their potential.

Defining Robotics and Automation: Key Concepts

Robotics and automation are two pillars of technological progress in business. Robotics centers on creating machines—robots—that can perform tasks, sometimes independently, using sensors, actuators, and control systems. These programmable machines interact with the physical world, handling everything from material handling to welding and assembly.

Automation, in contrast, refers to the use of technology to perform tasks with minimal human input. This encompasses everything from simple programmable thermostats to advanced industrial automation systems and business process automation. Automation technology is applied to both physical processes and virtual environments, such as software automating repetitive office tasks.

Both robotics and automation overlap in business process automation. Robots can execute physical tasks, while software automation (like RPA bots) handles digital workflows. Together, these tools enhance efficiency, reduce human error, and allow companies to refocus human talent on higher-value responsibilities.

Major Differences and Overlapping Areas

Physical robots and software robots may sound similar, but their roles diverge. Physical robots—think industrial robots on factory floors—tackle tasks like lifting, assembling, or welding by interacting directly with materials. These machines are programmable and adaptable, thriving in environments where precision and repetition are crucial.

On the flip side, software robots (often called RPA bots) work in the digital realm. They automate repetitive computer-based workflows, such as data entry or scheduling, within a virtual environment. While they don’t manipulate objects, their impact on business efficiency is undeniable.

Despite their differences, both forms of automation technology often work hand-in-hand. For example, a manufacturing plant might use industrial robots for physical assembly while deploying RPA software to manage inventory records and supply chain logistics. This blend of physical and software automation unlocks new possibilities for process automation and business growth.

Types of Automation Technologies Shaping the Future

Automation technology is constantly advancing, bringing fresh possibilities to industries worldwide. Businesses now have access to various types of automation—from sophisticated industrial robots to intelligent process automation software.

These innovations address different needs: some focus on physical processes like material handling, while others streamline virtual or administrative tasks. As process automation evolves, companies must choose the most suitable technologies to remain competitive and efficient. Let’s explore the main categories shaping the future of work and industry.

Industrial Automation Systems

Industrial automation has become the backbone of modern manufacturing, leveraging programmable machines to perform physical processes with minimal human input. These systems are designed to optimize production speed, safety, and precision.

A few key highlights include:

- Material handling systems that move, sort, and package goods, improving throughput and reducing manual labor.

- Programmable machines, like CNC equipment, that can be reconfigured for various manufacturing tasks, increasing flexibility.

- Automation of physical processes such as welding, painting, and assembly, ensuring consistent quality and high productivity.

Industrial automation also allows companies to operate around the clock, delivering efficiency that manual labor alone can’t match. With growing adoption, manufacturers benefit from reduced errors and operational costs, while workers are freed from hazardous or repetitive duties. Next, let’s see how software robots are changing business process automation.

Robotic Process Automation (RPA)

Robotic Process Automation (RPA) streamlines repetitive tasks through the deployment of software robots, enabling organizations to enhance operational efficiency. By automating business processes, RPA minimizes human intervention, reducing the likelihood of human error and optimizing resource allocation. This form of automation technology leverages machine learning and artificial intelligence to execute both simple and complex tasks. RPA tools are particularly beneficial in sectors like financial services and customer service, where the need for precision and speed is paramount in achieving digital transformation.

Industry Applications: Where Robots Automation is Making an Impact

Industries around the world are adopting robots automation and automation technology to solve unique challenges and enhance business process efficiency. Industrial robotics and software robots are now used far beyond just manufacturing, touching sectors as diverse as logistics, healthcare, and agriculture.

By automating both physical and digital tasks, companies can achieve greater speed and reliability. Let’s look closer at how the use of automation is transforming vital industries, opening doors for innovation and growth.

Manufacturing and Assembly Lines

Manufacturing has long been a proving ground for robots automation, where industrial robots are instrumental in transforming assembly lines. These programmable machines can assemble, weld, paint, and package goods with a level of speed and precision that human workers simply can’t match.

On today’s shop floors, process automation frees employees from repetitive and sometimes hazardous tasks. For example, industrial robots can work 24/7 without fatigue, ensuring high-volume output and consistent quality. This allows human workers to focus on monitoring, quality assurance, and problem-solving.

The result is a leaner, more agile manufacturing process, where downtime is reduced and efficiency is continually optimized. As companies aim to meet rising demand and tighter deadlines, investing in robots automation is becoming a clear strategic advantage.

Healthcare, Logistics, and Agriculture

Robots automation is also changing the face of healthcare, logistics, and agriculture. In hospitals, collaborative robots assist surgeons with remarkable precision and consistency, while automated medication dispensers ensure patient safety.

In logistics and supply chain operations, automation technology streamlines material handling and inventory management, leading to faster deliveries and lower costs. Meanwhile, agriculture uses robots for everything from planting seeds to harvesting crops, reducing labor intensity and enhancing yield.

- Healthcare: Surgical robots and automated medication systems improve accuracy and patient outcomes.

- Logistics: Automated warehouses and robotic picking systems boost efficiency and minimize errors in distribution.

- Agriculture: Autonomous tractors and drones monitor crop health, automate planting, and enable precision farming.

Across these industries, the use of automation not only improves productivity but also opens new opportunities for skilled work and innovation.

Benefits and Challenges of Integrating Robots Automation

Implementing robots automation brings powerful benefits, from lower costs to increased output and fewer mistakes. Automation software and process mining tools help companies uncover inefficiencies, leading to smarter business processes and better resource allocation.

However, challenges remain. High initial investments, integration complexity, and the need for skilled talent can slow adoption. Balancing the benefits of RPA and robots automation with these hurdles is essential for successful transformation. Next, let’s examine the specific efficiency and workforce impacts you should consider.

Efficiency Gains and Cost Reductions

When businesses adopt automation software and robots automation, efficiency soars. Machines and software can perform repetitive tasks around the clock, with no risk of human error or fatigue. This means fewer mistakes and less rework, which translates directly into cost savings.

Automated systems streamline business processes, making it easier to track performance, maintain quality, and scale production. For example, companies often report overtime reductions of up to 15% and error rates cut by 25% after integrating robotics, according to industry studies.

Beyond labor costs, process automation reduces waste, improves uptime, and enables predictive maintenance. These benefits free up your workforce to tackle more creative or customer-focused tasks. As more organizations recognize these gains, robots automation will only become more central to day-to-day operations.

Workforce Evolution and Human Collaboration

The rise of robots automation is driving a new era of workforce evolution, where human collaboration with machines is becoming the norm. Rather than replacing employees, automation technology is shifting roles and empowering staff to focus on higher-value work.

- Human intervention remains crucial for complex tasks requiring judgment and creativity.

- Collaborative robots, or cobots, are designed to work safely alongside people, enhancing productivity without risking human safety.

- Training workers to oversee, maintain, and program robots opens pathways to new, more specialized careers.

As automation takes on routine or hazardous tasks, you’re freed to concentrate on innovation, customer service, and strategy. This human-machine partnership isn’t about replacement—it’s about amplifying what your workforce can achieve. Adapting to this shift ensures your business stays agile, resilient, and ready for the future.

The Future of Robots Automation: Trends to Watch

Digital transformation is rapidly accelerating, with artificial intelligence and intelligent process automation reshaping industries. The future of robots automation promises even smarter factories, more adaptive automation software, and far-reaching business process improvements.

Emerging trends point to deeper integration of AI, increased focus on sustainability and ethics, and tighter regulatory oversight. Staying ahead of these changes is key to maximizing the value of automation technology for your organization. Here’s what you need to know about what’s coming next.

Artificial Intelligence Integration and Smart Factories

Artificial intelligence is quickly becoming the brainpower behind modern robots automation. By combining AI with machine learning, computer vision, and image recognition, smart factories can analyze data, adapt in real time, and optimize operations without constant human intervention.

This evolution enables robots to handle more complex, variable tasks and make split-second decisions. The expected future growth of robots automation in U.S. industries is robust—according to recent Harvard Business Review insights, investments in AI-driven automation software and RPA implementations are set to accelerate as companies pursue digital transformation.

For manufacturers, smart factories mean predictive maintenance, higher quality, and the ability to customize products efficiently. As AI technologies become more accessible, even smaller businesses can harness the power of intelligent process automation to stay competitive and relevant in a fast-changing market.

Sustainability, Ethics, and Regulatory Considerations

As robots automation becomes more widespread, questions of sustainability, ethics, and regulation are moving center stage. Companies must consider how automation affects human workers, customer service standards, and environmental footprints.

Are robots automation taking away human jobs or creating new opportunities? The answer is nuanced. While some routine roles may disappear, automation technology often spurs workforce evolution by creating specialized positions in programming, maintenance, and oversight. As Bill Gates has noted, “Automation frees people from repetitive tasks so they can focus on things that only humans can do.”

Regulatory bodies are increasingly focused on ensuring fair treatment, data privacy, and safety as more automation enters the workforce. Companies must stay proactive, ensuring both ethical standards and legal compliance as they adopt new technologies. Striking this balance is critical for long-term success and trust with employees and customers alike.

Conclusion

The era of robots automation is not just a trend; it's a fundamental transformation reshaping industries across the globe. By understanding the various technologies and applications in robotics and automation, businesses can harness efficiency gains, cost reductions, and enhanced collaboration between humans and machines. As we look to the future, the integration of artificial intelligence, sustainability efforts, and ethical considerations will continue to play a crucial role in how industries evolve. Embracing these changes will not only prepare organizations for the challenges ahead but also position them as leaders in their respective fields. If you're ready to explore how robots automation can transform your business, reach out for a consultation today!

Frequently Asked Questions

Are robots automation taking away human jobs or creating new opportunities?

Robots automation isn’t just replacing human work—it’s transforming it. While some repetitive jobs are automated, workforce evolution brings opportunities in programming, oversight, and innovation. Automation software enhances productivity but still relies on human judgment for complex and creative tasks.

How do companies choose between automation and robotics solutions?

Companies assess their business process needs to decide between process automation and robotics. Physical robots suit tasks in manufacturing or material handling, while software automation is best for virtual environments. The type of automation chosen depends on both workflow requirements and operational goals.

What is the expected future growth of robots automation in U.S. industries?

Robot automation is set for robust growth as digital transformation accelerates. Harvard Business Review notes a sharp rise in RPA implementations and related software solutions, with U.S. industries leading in investment and adoption to stay competitive and efficient in a global market.