The Future of Work: Robots Automation Trends to Watch

Key Highlights

- Fast growth in robotic process automation and artificial intelligence is changing how businesses use automation software to manage repetitive tasks.

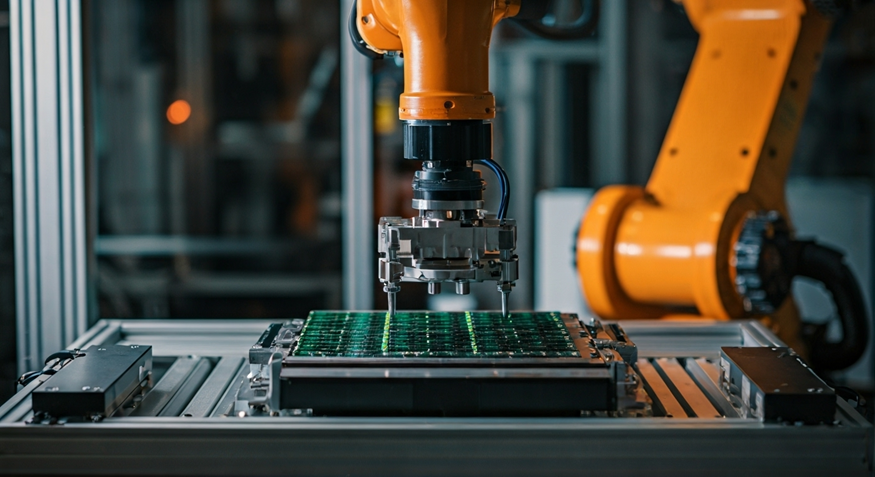

- Industrial robots and collaborative robots are making big changes in material handling. They help keep manufacturing and logistics work both accurate and fast.

- Intelligent process automation helps office work by making business process automation and customer service easier to handle.

- Automation technology is now used in healthcare, financial services, and retail because of new ways to use image recognition and robotics.

- The need to teach the workforce new skills keeps growing as people have to work with new types of automation and face digital transformation.

- Smarter workplaces are now common. Computer vision, RPA bots, and machine learning tools help the workplace to be safer and better for everyone.

Introduction

Robots and automation are changing the way people work all over the world. Now, you can see industrial robotics on factory floors and automation software in today’s offices. These are some of the key drivers behind digital transformation in many fields. With the help of intelligent process automation tools, robots are able to do complex tasks. There is much less need for human intervention. This also helps to cut down on human error and improve how well companies work. People in business have to know the scope and impact of process automation, industrial robotics, and these types of new tools. It is now even more important to stay ahead and keep up in this new time of change for human work.

Understanding the Evolution of Robots and Automation

The story of robots and automation technology shows many years of hard work in computer science and engineering. At first, robotics started with simple programmable machines that could do hands-on jobs. Now, they have grown into smart devices that can change and react to new things around them. At the same time, automation technology has changed a lot. It covers everything from software automation to jobs that need physical processes. This helps businesses make their work smoother and boosts their productivity.

When robotics and automation come together, they create new ideas by joining industrial robots and smart computer software. With this, people, businesses, and industries can get better efficiency and safer places to work. There are also new chances for human intervention and for making each business process run better.

Defining Robotics and Automation in the Modern Workplace

Robotics and automation are important in the workplace now. These two things are different but work closely with each other. Robotics comes from computer science and engineering to make real machines, or robots, that can do jobs by themselves. These programmable machines can work in the physical world or in the virtual world. They help to cut down on human intervention by doing jobs that are repetitive or unsafe.

Automation is about using technology, like software bots or industrial machinery, to help with business process automation. Software automation takes care of virtual tasks, such as those in financial services or customer service. Industrial automation is about the physical world, such as work on assembly lines or material handling.

When robotics and automation technology come together in process automation, they help businesses cut human error and get better at what they do. They also help with digital transformation by making work smoother. This mix lets companies use human judgment with the smart and quick work of robots. In this way, the modern workplace gets the benefits of both people and machines working as one team.

Key Milestones Shaping the Industry

Milestones in robotics and automation technology keep changing many industries. For example, industrial robots have changed how things are made. They let people work in safer places and cut mistakes by as much as 25%, according to Harvard Business Review. These tools work all day and night. They help with process automation jobs like welding and packing.

The rise of robotic automation added machines with parts that you can program. This made it possible to have big production lines that cost less money and time. Better computer software then let people use RPA implementations. These things copy what a human worker does on a computer. This helps people finish tasks faster and keep track of things better.

Now, people are mixing machine learning with robotics. This helps build smarter process automation systems. These systems can change the way they handle complex tasks as they go. Such milestones show the big changes brought by both software solutions and physical robots. Areas like healthcare, logistics, and retail use them every day. They help move us into a smarter world that uses automation.

Types of Automation Transforming Work

Automation can change the way people work in the office and the factory. Robotic process automation (RPA) uses bots that help with software tasks. These bots take care of repetitive jobs, like entering data and making schedules. This kind of software automation lets businesses build better and more cost-friendly business process models.

At the same time, industrial automation updates how things get done in the real world. Smart machines and material handling robots now do jobs like putting things together, painting, and packing. They work fast and get it right. With these two types of process automation, different industries can meet their own needs. This shift is changing human work for the better.

Industrial Automation and Its Impact

Industrial automation uses physical robots to make labor jobs faster and easier. These machines do tasks that are repeated often, like material handling and welding. They help stop mistakes that may come from human error. This leads to work being done with high accuracy.

The robots help with real physical processes. They work in places like assembly lines, which takes some of the load off workers and keeps the same level of quality every time. Process automation also helps keep people safe because the robots can go into areas that could be risky for humans.

When companies use robots in manufacturing, this can help them make more products in less time and have less downtime. Things like CNC machines and automated inspection gear show how industrial automation has changed our way of doing large-scale work.

Office and Software Automation Solutions

Office automation solutions like RPA bots change the way businesses deal with repetitive tasks for better workflows in online spaces. The main benefits are:

- Streamlining repetitive processes: RPA bots set up meetings and enter data in different systems with speed.

- Enhanced governance: These bots point out any changes in rules that don't match the set standards.

- Improved business process control: Task analysis makes it easier for business managers to spot and fix mistakes.

- Cost savings: Bots can grow with the company, which lowers costs related to workers.

Software robots with intelligent process automation now help with more complex office tasks and need very little human judgment. These tools let workers spend more time on important business process tasks, which helps them be more productive and get more done.

Robotics Applications Across Industries

Robotics joined with automation technology is helping many industries, not just manufacturing. In retail, robots help with customer service. They can guide shoppers and help manage stock. In healthcare, robotic systems help with surgeries. They make the process more accurate and safe for patients.

Financial services are using business process automation to make their work better. Software solutions like RPA bots help with many business processes. These include virtual tasks such as looking for fraud and assessing risks. This wide use of process automation shows how valuable automation technology is for different fields. It can help improve results at work in many ways.

Manufacturing and Logistics Innovations

The rise of industrial robotics and collaborative robots is changing the way we do manufacturing and logistics. Robot automation helps with repetitive tasks like putting cars together and sorting out packages. This means more speed and better accuracy.

Collaborative robots, or cobots, joined with advanced RPA implementations, help offer flexibility. This mix lets robots change what they do based on what people tell them. It is a major step forward in having humans and robots work together in the same space today. Process mining helps a lot with logistics. It shows where things are slow or wrong and gives better ways to work.

| Manufacturing Focus | Logistics Focus |

|---|---|

| Welding and assembly | Sorting and packaging goods |

| Materials inspection | Inventory optimization |

| Collaborative robots | Automating delivery processes |

These changes help people in different industries face their day-to-day problems with better technology.

Healthcare, Retail, and Service Sector Advancements

Robotics and automation technology play a big part in making process automation smarter in healthcare. Medical teams now use robots to help them do surgeries with more accuracy. This helps to cut down on human error. RPA bots are also used in retail to handle tasks at the checkout and to help guess when to order more stock.

In the service industry, robots with image recognition help with customer service. These tools can handle customer questions on their own. This lets people at work spend more time on hard problems that need a human touch.

When robots slowly become part of these areas, there is a clear move towards better efficiency. This also shows what business process automation can do and how companies can scale up their work with automation technology.

Emerging Trends in Robots and Automation

Robotic automation is changing the future with smart technologies. Now, rpa tools are more flexible because of better machine learning. There are improvements in the way software solutions and physical robots work together, making it easier for them to help each other.

New trends for cobots are helping to make the way they work with people better. This is leading to more safety at work. As AI systems get better, robotics that use intelligent process automation are set to become key tools. These tools mean workers will not have to do so many hands-on jobs, and can spend more time on creative work.

Artificial Intelligence Integration

Artificial intelligence is changing automation technology. It connects robotic automation with machine learning for better problem-solving. AI-powered software solutions do jobs that need accuracy, like spotting fraud risk in financial services.

Machine learning is also a big help in robotic automation. It lets robots change and respond to new situations. With computer vision inside the robots used in factories, these machines can now notice more mistakes in products.

This mix of tools helps businesses use smarter and more flexible software solutions. With artificial intelligence, computer vision, and robotic automation working together, automation technology is mostly here to help human work, not replace it.

Collaborative Robots (Cobots) in the Workplace

Collaborative robots, also called cobots, fit easily into many types of work. They help people do more and make work faster. Unlike industrial robots that work by themselves, cobots team up with people at the job. They use machine learning and computer vision to do repetitive tasks in the workplace. This use of cobots helps cut down on human error and takes the hard work off people. Workers then get to spend more time on complex tasks and problem-solving that need human creativity. As more companies start to use process automation like this, the benefits of RPA and intelligent process automation show clearly. This change is opening up a new way for people to work.

Conclusion

As we look at the future of work, it is easy to see that robots and automation are going to be very important. The use of artificial intelligence and collaborative robots is changing how we do our jobs. This makes our work faster and better. It helps us be more productive. It can look scary to switch to new tools like this, but it is a good way to find new ways to grow and to make things better. If we keep up with new trends and learn new skills, we can do well as things change. If you want to see how automation can help your business or job, you can get in touch for a free consultation. We can get ready for these exciting changes together.

Frequently Asked Questions

How are robots impacting job opportunities in the US?

Robots in automation help shift the workforce, so people can focus on creative and strategic work. When some jobs that are repeated many times go away, digital transformation helps make new roles. There will be jobs like watching over robots, programming them, and keeping them running well. This change gives people more chances to use their skills in other ways.

What skills are essential for working alongside automation and robots?

Key skills for this field are knowing about computer science, automation technology, and how human intervention works. You need to be able to program robots, work with data, and keep an eye on smart systems. These things are very important as more businesses start to use advanced tools like collaborative robots and RPA software.

Can small businesses benefit from workplace automation?

Yes, small businesses get more done with RPA implementations. It helps them finish repetitive tasks like data entry, making things faster and easier. New automation software and other software solutions help keep costs down. RPA bots also help these companies grow by making their business process work better and scale up as needed.

What ethical challenges arise with increased automation?

Ethical challenges come up in process automation. There is a need for careful checks to stop mistakes made by algorithms. Keeping human judgment in the process makes sure people take responsibility. This also helps with worries about privacy, losing jobs, and actions done by machines. By doing so, it keeps things fair.

Will robots completely replace human workers in the future?

It is not likely that robots will fully take over all human work. Automation helps by doing jobs that are predictable and often repeated. But, human intervention is still needed. People play an important role in watching over the work, being creative, and making decisions. This keeps a good balance between how fast robots can work and the care people give by overseeing things.

What are the benefits of implementing robot automation in industries?

Implementing robot automation in industries enhances efficiency, reduces human error, and lowers operational costs. Robots can work continuously without fatigue, increasing productivity and allowing human workers to focus on more complex tasks. Additionally, automation can improve safety by handling dangerous jobs, creating a safer workplace environment overall.