Beginner’s Guide to the Automatic Manufacturing System

Key Highlights

An automated manufacturing system employs advanced technologies to streamline the production process, reducing the dependency on a human workforce while increasing accuracy and speed.

- It integrates industrial automation tools like control systems, sensors, and robotics to optimize operations.

- Various types of automation, such as fixed, programmable, and flexible, serve unique needs in the manufacturing process.

- Core components include machine tools, PLCs, and sophisticated software systems.

- Industrial robots and automation technology enhance production efficiency while minimizing the risk of human error.

- Automation supports continuous improvement in supply chain

- operations and production systems

Introduction

Modern manufacturing systems are changing fast because of automation in the production process. When you let machines and new systems do more tasks, you get more work done in less time. This means there is less need for people to do the same jobs, and you can meet more customer needs. Automation helps your company grow quickly, and it also helps you get better control of quality and lowers mistakes. If you are looking at tools for your own production line or thinking about making a big change, you have to know how automation works at the base. This is key if you want to do well in the tough market today. Beginner's Guide to Automatic Manufacturing: Key Concepts

Understanding Automatic Manufacturing Systems

An automatic manufacturing system uses technology to run processes with no need for people to help. This makes the production line smooth and faster. These systems are important for getting more work done and saving money. They are great to use in places where there are a lot of repetitive tasks or where high precision is needed.

Industrial robots are often used to put parts together, and sensors check the quality at different steps. With the help of these smart tools, these systems make sure work is done with a lot of precision. Automatic systems also let the business be flexible, so it can handle custom orders. This is why so many companies use them as the backbone for new and growing ways to work.

What Makes a System "Automatic"?

What makes an automated system stand out is that it can work with very little help from people. These systems use advanced control systems to keep everything running right within set limits. In a well-run production environment, machines now do jobs that people used to do, and this helps to lower the risk of human error.

These systems are good at doing repetitive tasks again and again with the same results and at a fast pace. For example, automated conveyors in a factory can move products down the production line with ease. This helps to stop the slowdowns that can happen when people move things by hand.

Automated systems also use sensors and computer tools to watch how they are doing as they work. The idea is not just to make work faster or smoother. Automation is about keeping things on track and always getting better. By letting machines handle boring or hard jobs, companies can do better at what they make and use their time to find new ways to improve.

Key Components of an Automatic Manufacturing System

Every automatic manufacturing system depends on a few important parts to keep everything working right and on time. These parts are:

- Machine tools that do jobs like cutting, shaping, or helping with other kinds of machining work.

- Sensors that pick up real-time data. This data helps with quality control and keeps things safe.

- PLCs, or Programmable Logic Controllers, that help with automation and control of equipment around the factory floor.

- Software systems that let machines talk to each other. This helps build better connectivity across the production system.

These machines and new tech come together to create a more accurate and efficient manufacturing process. For example, sensors can spot errors and help fix problems fast. PLCs make small changes to keep everything on track in real time. Software with good connectivity helps line up work schedules, so all machines run as a team. By putting these parts together, people who work in manufacturing can make more products, cut downtime, and get better results from the production system.

Types of Automation in Modern Manufacturing

In modern manufacturing, the

types of automation you use depend on what you need to make. The main types of automation are

hard automation,

programmable automation, and flexible automation.

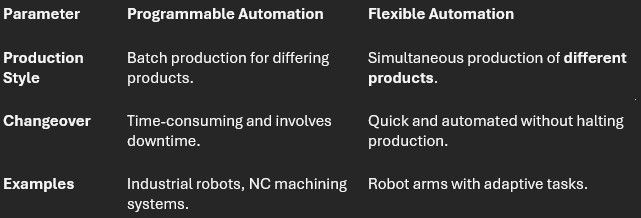

Each type works best in its own way. Hard automation is good for jobs that push out a high volume of items over time. Programmable automation helps when you have batch production, where you make groups of items instead of all the same thing. Flexible automation is the way to go if you need to move fast and make different products at once.

By picking the best method, people in the industry can get the most out of their work. They can also make sure their production systems stay up to date and ready for any changes the market may bring.

Fixed Automation Explained

Fixed automation, sometimes called hard automation, is made for repetitive tasks. This type of automation is used a lot for large production jobs. After someone sets it up, these systems stick to a planned production schedule. They do the same thing over and over, which helps with consistency and making a lot of products fast.

One place where fixed automation is used a lot is in the automotive industry. For example, some transfer lines in car factories can make the same part quickly over and over. Pressing machines in the plants shape parts the same way every time, so each one is made with high precision. But these systems are not good at change. If the company wants to make something new, it could lead to long downtime.

Even with this issue, fixed automation is the best choice when you need things to stay the same and go fast. By getting the most out of the machines (equipment effectiveness), it cuts down on human mistakes. That also helps speed up all the parts of the job. If you need to make the same thing in big amounts, this is one of the best solutions for the job.

Programmable and Flexible Automation

Both

programmable automation and

flexible automation help in dynamic production, but they are not the same in how they adapt and how efficient they are. With programmable automation, the setup fits

batch production. This means the machinery runs for one group of products. After that, it needs to be reprogrammed each time to start a new job.

Flexible automation cuts down on delays when it's time for a changeover. The swaps between jobs can happen fast, without stopping the whole line, which saves from long downtime. This is a big plus for factories that always make different products. It helps them pick up new work quickly and meet changing needs. Because of this, flexible automation helps these workplaces to adjust fast. This is really good for industries where customers want new changes all the time, and it keeps production moving smooth with less downtime.

Real-World Applications of Automatic Manufacturing

The use of industrial automation has changed many industries in a big way. It helps make production processes faster and makes the supply chain work better.

In everyday work, robotic arms put parts together with a lot of

precision. You will find

automation technology keeping track of inventory levels at every factory. Complete tools like

CIM connect every part of manufacturing, so things move more smoothly. With all these new tools, productivity goes up and you get the same quality each time. That is why using

automation is a good solution for businesses that want to be strong and do well today.

Robotics and Automated Machinery

Robotics play a big part in industrial automation. They have changed the way factories work. Machines like industrial robots do repetitive tasks like putting things together and packing. They work with great precision. Robotic arms can stack items fast. This cuts down on delays and helps reduce errors.

These robots can also do complex tasks, like welding and drilling small or tricky parts. Industries like aerospace need this kind of precision to meet strict rules and standards. Automation helps manufacturers stay away from bottlenecks. It also lets them grow their operations with ease.

Automation also makes the workplace safer. Robots do the tasks that put people at risk. This keeps production smooth and safe at the same time. For these reasons, robotics and industrial robots are very important for keeping up with productivity and looking after the people who work in the factory.

Computer-Integrated Manufacturing (CIM)

Computer-integrated manufacturing, or CIM, is changing how people see the entire production process. It does this by using automation and digital tools to help different manufacturing systems work better together. Because of this, the overall efficiency goes up at every step of the production process. CIM uses artificial intelligence and machine tools to watch over what is happening in real time. This means less downtime and more people get the work done.

CIM creates good connectivity between supply chain management and equipment effectiveness. It helps production schedules shift to fit different types of automation. All of this helps factories react faster to new things in the supply chain and improve how they use all the different types of automation.

Beginner’s Guide: Getting Started with Automatic Manufacturing Systems

Looking into an automated manufacturing system might look hard at first, but there are steps that help make it easier. You need to know about your own manufacturing process and find the automation technology that fits best for you.

Getting the right tools and planning out the steps can help beginners learn how to be more efficient over time. With automation, companies can make the work go smoother and get ready for what will come next. This makes automation really important if you want your business to last and do well.

Essential Equipment and Resources You’ll Need

To set up an automated manufacturing system, you need to have the right resources and tools. Key things you will need are:

- Machinery that does manual work by itself.

- Sensors to measure and watch the system in real-time.

- CNC tools to help with precise work and machining.

- CAD and ERP software for design and to run daily operations.

All of these parts work together in a good way. For example, CNC machines take care of jobs that need precision, and ERP systems connect the full supply chain. If you put money into these, you help your business be better and stronger.

Step-by-Step Process for Setting Up an Automatic Manufacturing System

To launch an automated manufacturing system well, you need to follow clear steps:

- First, look at your current production process and find the main problems.

- Next, pick the right automation technology that can fix these issues.

- Cut down on downtime by adding each part of the system one at a time.

- Build strong connectivity with IoT devices to keep everything linked.

These steps help you move forward without trouble. When you know your own goals, you lower the chance of something going wrong and make it easier to get long-term benefits. Keep working on improvements after you use automation so you can keep seeing good results.

Step 1: Assessing Your Manufacturing Needs

Understanding your production environment is the first step you need to take. Look at your product design and find things like bottlenecks that slow things down. Use the right metrics to see how reliable everything is.

For instance, if you see bottlenecks during assembly, using automation like robotic arms can help. Focusing on these things makes sure you spend money on the right production environment problems. By checking what you really need, you can match the best solutions to your actual demands.

Step 2: Choosing the Right Automation Technology

Picking the right automation technology is very important. Technology like AI, PLCs, and IoT-based algorithms can help make things better and raise how much you get done in the production process. The type of automation you choose, like programmable or fixed, will depend on what your system needs.

For example, choosing PLCs instead of more complicated systems could be better for smaller jobs. You have to look at the cost and what you get from it, so any growth makes sense.

Conclusion

In the end, choosing automatic manufacturing systems can really help your business work better and faster. If you learn about the main parts and different types of automation, you will be able to see what you need and pick the best tools. Some of these helpful tools are robotics and computer-connected manufacturing, and they are made to make things smoother at work, cut down costs, and make products better. When you start with automation, remember that setting up your system right and always learning new things will help you get the most out of it. If you want, you can ask for a consultation to see how manufacturing systems and the right types of automation can help you take your work to a higher level.

Frequently Asked Questions

What industries benefit most from automatic manufacturing systems?

Manufacturing systems are very helpful in the automotive industry, aerospace, pharmaceuticals, and chemical manufacturing processes. These areas use automation to get more precision, be efficient, and make it easier to scale up their work. Robotics and other connected tools help these industries with their complex production needs. They also help keep the quality and the amount of work steady.

How expensive is it to implement automation for beginners?

Automation can cost different amounts. You will need money for equipment, software, and integration. At first, these costs may look big. But when you use automation on your production line instead of doing manual processes, you save money over time. It helps increase profits for you. If you are new to automation, you can start on a small scale. This way, you can manage your budget in a good way.

Are automatic manufacturing systems difficult to maintain?

The upkeep of automated systems depends on the state of the machinery, the sensors, and the skills of your human workforce. Doing regular servicing helps cut down on any unexpected downtime. When you train your human workforce to run and watch over these advanced systems, it makes everything go smoother. This also helps keep things working well over time.

Can automation improve product quality and consistency?

Yes, that is true. Automation helps make the product quality better by cutting out human mistakes and making the same process happen each time. By using analytics and automatic checks in the production process, businesses can get more consistency. This makes customers happier and lowers the number of defects as time goes on.

What is an automatic manufacturing system and how does it work?

An automatic manufacturing system integrates advanced technology to streamline production processes. It utilizes machinery and software to automate tasks, reducing human intervention. By coordinating operations such as assembly, inspection, and packaging, it enhances efficiency, accuracy, and productivity while minimizing costs and errors in manufacturing environments.

What are the key advantages of automatic manufacturing?

Automatic manufacturing offers numerous advantages, including increased efficiency, reduced labor costs, and enhanced precision. Automation streamlines production processes, minimizes human error, and boosts output rates. Furthermore, it allows for consistent quality control and can quickly adapt to market demands, making it a crucial component of modern industry.