Understanding Automation PLC: A Comprehensive Guide

Key Highlights

- Programmable logic controllers (PLCs) form the backbone of industrial automation by enabling efficient control of machinery and processes.

- Advancements from bulky relay-based systems to modern PLCs have increased flexibility, reliability, and scalability within control systems.

- PLC programming uses intuitive languages such as ladder logic and structured text to streamline process control and enable easy system updates.

- Core components of a PLC system—including the CPU, I/O modules, and power supply—work together for real-time decision making.

- PLCs seamlessly integrate with human machine interfaces and communication protocols to support diverse industrial applications.

Introduction

Programmable logic controllers, often called PLCs, are the brains behind modern automation systems. Used extensively across industrial applications, these devices gather information from sensors, process data according to custom logic, and control machinery or processes accordingly. The adoption of PLCs has transformed manufacturing, energy, and other sectors by boosting efficiency, reliability, and flexibility. With easily programmable features and strong adaptability, PLC automation delivers benefits such as reduced downtime and improved process control, enabling industries to operate smarter and more safely.

Foundations of PLC Automation

The foundation of PLC automation lies in replacing traditional relay-based control systems with programmable controllers. These systems revolutionized industrial automation by simplifying process control and enhancing adaptability. PLCs automate complex machinery and systems by processing input data and providing output commands in real time. Unlike early relay-based systems, PLC automation offers faster response, easier reprogramming, and reduced maintenance. As you dive deeper, it’s essential to understand the distinctions between PLCs and other automation approaches.

Let’s explore the definition and core features of programmable logic controllers, followed by the transition from relay-based to PLC systems.

Defining Programmable Logic Controllers (PLCs)

Programmable logic controllers (PLCs) are specialized industrial computers designed for real-time control of machinery and processes. They play a vital role in automation systems, allowing for precise process control and integration with various input and output devices. Characterized by their use of programming languages such as ladder logic, modern PLCs facilitate complex tasks in diverse industrial applications, from assembly lines to temperature control. Their capability to manage safety protocols and communicate with supervisory control and data acquisition (SCADA) systems enhances operational efficiency and reliability.

Evolution from Relay-Based to PLC Systems

Industrial automation once relied on cumbersome relay-based systems for the control of machinery. These systems, consisting of banks of interconnected relays, required extensive manual wiring and were inflexible for changing process requirements. As demands for efficiency and adaptability grew, the late 1960s saw a turning point with the introduction of PLCs. Bedford Associates, working with General Motors, pioneered the shift by designing the first PLC to replace complex relay logic in automotive manufacturing.

Key advantages of PLCs over relay-based systems include:

- Simplified programming: PLCs use logic-based programming instead of manual rewiring, making process changes quick and straightforward.

- Greater durability: With no moving parts, PLCs withstand vibration, temperature extremes, and electrical noise better than relays.

- Enhanced troubleshooting: Modular PLCs allow for easier isolation and repair of faulty components, minimizing system downtime.

The shift to PLCs marked a new era for control systems, enabling industries to adopt more sophisticated, responsive automation strategies.

Core Components and Architecture of a PLC

Understanding the architecture of a PLC system is vital in grasping its efficiency within control systems. Each PLC is built with essential elements: a central processing unit (CPU), memory, input/output (I/O) modules, and a power supply. These components work in tandem to monitor industrial processes, execute program logic, and control connected machinery. The seamless integration of these parts ensures that PLC automation remains reliable and adaptable, even in complex environments.

Next, it’s helpful to look closer at the CPU and memory, followed by I/O modules and communication interfaces.

Central Processing Unit (CPU) and Memory

The heart of any automation system lies in the central processing unit (CPU) and memory, where complex tasks are executed efficiently. This processing unit manages data flow and executes PLC programs that control machinery in real time. Memory stores crucial information, such as program code and configuration settings, allowing for seamless operation of input and output modules. Advanced programming languages, like ladder logic and function block diagrams, enhance system versatility, enabling effective control of industrial processes and providing reliable supervisory control.

Input/Output (I/O) Modules and Communication Interfaces

Input/output (I/O) modules serve as essential components in programmable logic controller systems, facilitating the seamless exchange between control and external devices. These modules manage both input devices, such as sensors, and output devices, like electric motors, ensuring real-time process control. Communication interfaces enhance connectivity within automation systems, supporting various protocols for effective data transmission. By utilizing function block diagrams and ladder logic, I/O modules integrate numerous industrial applications, enabling complex tasks to be executed efficiently across remote locations.

How PLCs Work in Industrial Automation

PLCs are the core of industrial automation, linking sensors and actuators to automate everything from simple machines to entire production lines. Through plc programming, these controllers interpret real-time input data, execute process control logic, and manage output devices for precise and responsive system operation. Their versatility makes PLCs indispensable for automated systems across various industrial processes, from food processing to temperature control.

Now, let’s examine the PLC scan cycle and explore real-world examples of automated processes using PLCs.

PLC Scan Cycle Explained

A PLC operates in a continuous loop known as the scan cycle, which is fundamental for real-time program execution in control systems. The scan cycle consists of the following steps:

- Input scan: The PLC checks all connected input devices, collecting real-time data from sensors and switches.

- Program execution: It processes the data by executing the control logic written in plc programming languages, such as ladder logic or structured text.

- Output update: The PLC sends output signals to actuators, lights, motors, or other devices to perform the required actions.

After completing these steps, the PLC performs housekeeping tasks, such as internal diagnostics and system checks, ensuring reliability and safety. This entire scan cycle repeats rapidly—often every few milliseconds—so the system can react quickly to changes. Common programming languages used for PLCs include ladder logic, function block diagrams, and structured text, making process adjustments straightforward.

Real-World Examples of Automated Processes Using PLCs

PLCs are integral to a range of real-world industrial processes. Their ability to handle complex automation tasks makes them ideal for diverse applications:

- Assembly lines: PLCs synchronize conveyor belts, robotic arms, and pick-and-place machines to enhance speed and precision.

- Food processing: In facilities requiring strict temperature control, PLCs monitor sensors and adjust heating elements or chillers to maintain safety and quality standards.

- Electric motor control: PLCs manage the operation and safety of industrial motors, adjusting speed and direction based on process demands.

Industrial automation also relies on PLCs for packaging lines, material handling, and even utilities management. Their use in these applications demonstrates how programmable controllers streamline workflow, improve reliability, and ensure safety across a wide spectrum of industrial environments.

Types of PLCs Used in Automation

PLCs come in several types, each tailored for distinct automation requirements. The main categories include fixed, modular, and unitary PLC systems. Fixed PLCs offer a compact, cost-effective solution for small-scale control, while modular PLCs provide flexibility and scalability for growing systems. Unitary PLCs combine the CPU, input/output, and power supply in one enclosure, simplifying installation. Understanding these types helps ensure the right fit for your automation project.

Let’s compare fixed versus modular PLCs, followed by unitary and rack-mounted systems.

Fixed vs. Modular PLCs

When selecting a PLC system, the choice between fixed and modular types hinges on application needs:

- Fixed PLCs: Also known as compact PLCs, these units have a pre-defined number of input and output points and integrate all essential elements in a single enclosure. They are cost-effective, easy to install, and well-suited for simple, standalone applications.

- Modular PLCs: These systems consist of separate modules—such as CPU, power supply, and I/O modules—that can be assembled and expanded as needed. Modular PLCs offer unmatched scalability and flexibility, making them ideal for complex or growing automation projects.

Key considerations for selection:

- The complexity of the automation process and future expansion needs.

- Budget constraints and the required level of customization.

Choosing the right PLC type ensures the system meets current operational demands while supporting scalability for future requirements.

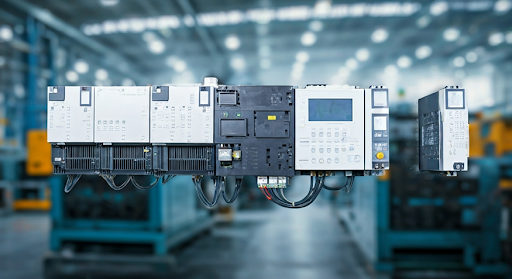

Unitary and Rack-Mounted PLC Systems

Unitary and rack-mounted PLCs offer distinct benefits for various automation scenarios. Unitary PLCs combine the CPU, input/output interfaces, and power supply within a compact enclosure, providing straightforward installation and efficient control for basic tasks. Their simple physical connection makes them ideal for applications with limited space or remote locations.

In contrast, rack-mounted PLC systems are modular, with each component—CPU, I/O modules, communication interfaces—installed in a common rack. This architecture allows for extensive scalability and customization, accommodating large, complex automation projects or facilities requiring frequent upgrades.

Important factors to consider when choosing between these systems include:

- The physical space available and ease of installation.

- The level of scalability and expansion needed for future growth.

Selecting the appropriate system ensures both performance and adaptability in your industrial control environment.

PLC Programming: Languages and Methods

PLC programming is essential for customizing control systems in industrial automation. Engineers use dedicated programming devices and plc programming software to create logic routines that direct how the PLC responds to input data. Several programming languages—including ladder logic, function block diagrams, and structured text—offer varying levels of complexity and visual representation. By selecting the right method, you can tailor your PLC system to unique process requirements and ensure seamless integration with other automation components.

Next, we’ll compare major programming languages and discuss tools for simulation, testing, and debugging.

Ladder Logic, Function Block, and Structured Text

Programming a PLC can be accomplished using several established languages, each suited for different tasks:

- Ladder logic: The most popular method, ladder logic visually resembles electrical relay schematics. It’s widely used for its intuitive structure and ease of troubleshooting.

- Function block diagrams: These use graphical blocks to represent functions and data flow, making them ideal for complex process control or systems involving multiple routines.

- Structured text: A textual programming language, structured text enables advanced logic and data manipulation, supporting more complex tasks than graphical languages.

Key advantages of using these languages:

- Engineers can select the most suitable programming approach based on process complexity.

- PLC programming software and devices facilitate straightforward development, simulation, and modification of control routines.

Choosing the right language ensures efficient process automation and effective system management.

Simulation, Testing, and Debugging Tools

Simulation, testing, and debugging are vital steps in developing reliable PLC programs. PLC programming software typically includes built-in simulation tools that let engineers model and test control logic before deploying it to real hardware. This process reduces the risk of errors and ensures the system performs as intended.

Debugging features allow for real-time monitoring of program execution, making it easier to identify and resolve faults or unexpected behaviors. Maintenance teams benefit from these tools, as they enable swift troubleshooting and minimize downtime during system upgrades or repairs.

Thorough testing is especially important for complex tasks or safety PLC applications, where precision and reliability are critical. By leveraging advanced programming devices, simulation environments, and diagnostic software, engineers can deliver high-quality control solutions that meet the rigorous demands of industrial automation.

Key Benefits of Implementing PLC Automation

Implementing PLC automation brings notable advantages to industrial operations. These programmable controllers increase system reliability, minimize downtime, and streamline process control, resulting in higher productivity. Their flexibility allows rapid adaptation to changing requirements, while scalability means systems can grow alongside business needs. Furthermore, PLCs are a cost-effective solution compared to older relay-based systems, making them a smart investment for industries looking to modernize and future-proof their operations.

Let’s examine how PLCs deliver increased reliability, reduced downtime, and benefits in flexibility and cost-effectiveness.

Increased Reliability and Reduced Downtime

PLCs are built for reliability in demanding environments, offering several features that minimize system failures and ensure continuous operation.

- No moving parts: Unlike mechanical relays, PLCs use solid-state electronics, making them resistant to wear, electrical noise, and harsh industrial conditions. This results in fewer breakdowns and lower maintenance needs.

- Safety and diagnostics: Advanced PLCs, including safety PLCs, automatically perform self-checks and diagnostics, quickly identifying issues and preventing unsafe operation.

A well-designed PLC system, paired with a dependable power supply, can withstand significant disruptions without compromising performance. By reducing unplanned downtime and enhancing process safety, PLCs help organizations achieve more consistent production and higher overall efficiency.

Flexibility, Scalability, and Cost-Effectiveness

PLCs provide unmatched flexibility and scalability to meet evolving automation needs.

- Adaptable programming: With modular PLCs, engineers can reprogram control logic or add new I/O modules as processes change, supporting business growth without large capital investments.

- Cost-effectiveness: Compared to traditional relay systems, PLCs require less physical wiring, reduce labor costs, and enable faster troubleshooting, leading to significant long-term savings.

Unitary PLCs are ideal for basic control tasks at lower costs, while modular PLCs are perfect for expanding operations as requirements increase. This mix of flexibility and cost-efficiency ensures that companies can start small and scale up their automation systems as operations demand, optimizing both budget and process efficiency.

Frequently Asked Questions (FAQs)

Curiosity often leads to many inquiries about programmable logic controllers (PLCs) and their applications in industrial automation. One common question is about the longevity and reliability of these systems, particularly in demanding environments like food processing and assembly lines. Another frequent concern relates to the complexity of PLC programming languages, such as ladder logic and function block diagrams. Understanding communication protocols and the role of input and output devices can also clarify how PLCs enhance control systems and ensure optimal process control.

What are the main differences between PLC automation and PC-based automation?

PLCs are purpose-built programmable controllers designed for real-time process control and reliability in industrial settings, while PC-based automation uses general-purpose industrial computers. PLCs excel at direct control of machinery, whereas PCs are better suited for supervisory control and data acquisition tasks.

Which industries most commonly use PLCs and why?

PLCs are widely used in industrial applications such as food processing, assembly lines, and temperature ranges requiring precise control of machinery. Their robust design, reliability, and adaptability make them ideal for manufacturing, utilities, and industries that demand consistent, safe operation.

What should be considered when selecting a PLC for a new automation project?

When choosing a PLC system, assess the number and type of output devices, need for analog inputs, capability to handle complex data, supported programming languages, and future expansion requirements. Ensuring compatibility with the project’s scale and complexity is crucial for long-term success.

Conclusion

In summary, understanding Automation PLCs is crucial for optimizing industrial processes and enhancing efficiency. With a solid grasp of the various components, programming languages, and benefits of PLC automation, businesses can make informed decisions that lead to improved reliability, reduced downtime, and significant cost savings. As industries continue to evolve, embracing PLC technology will allow organizations to stay competitive and responsive to changing demands. If you're ready to take your automation efforts to the next level, consider reaching out for a consultation to explore tailored solutions for your specific needs.