Exploring the Future of PLC and Industrial Automation

Key Highlights

- Programmable logic controllers (PLCs) are foundational to modern control systems, transforming how manufacturing processes are managed and automated.

- PLC systems have replaced traditional relay logic, significantly increasing efficiency and reducing human error in industrial environments.

- The architecture of PLCs, including modular PLCs, enables unmatched scalability and adaptability for industrial computers across multiple sectors.

- Ladder logic remains a core programming language in industrial automation, supporting precise control logic and real-time decision-making.

- PLCs support advanced diagnostics, predictive maintenance, and seamless integration with SCADA systems and the Industrial Internet of Things.

- Modern manufacturing relies on PLCs for flexible, reliable, and efficient automation—driving productivity and supporting future-ready operations.

Introduction

In the ever-evolving landscape of industrial processes, the role of programmable logic controllers transcends mere automation. These sophisticated controllers serve as the backbone of modern manufacturing, ensuring precision and reliability in operations. As industries embrace advanced automation systems, the integration of PLCs with technologies like the Industrial Internet of Things (IIoT) and SCADA systems reshapes the way production environments function. The transition from traditional control systems to these intelligent solutions signifies a pivotal advance in enhancing efficiency and reducing human error across various sectors.

The Evolution of PLCs in Industrial Automation

The journey of programmable logic controllers began in the late 1960s as a pivotal shift from traditional relay logic to more sophisticated programmable solutions. With the development of programmable controllers, industries experienced a significant enhancement in control systems, streamlining complex data handling and automating manufacturing processes. Key milestones, such as the introduction of modular PLCs, have allowed for flexible configurations, adaptability to extreme temperatures, and integration with advanced supervisory control systems, ultimately revolutionizing operational efficiency and productivity in various industrial environments.

From Relay Logic to Programmable Controllers

The transition from relay logic to programmable controllers marked a pivotal moment in automation technology. Relay-based systems, while effective for their time, were often limited by their complexity and physical wiring requirements. The introduction of programmable logic controllers (PLCs) revolutionized control systems, enabling more flexible programming and modular design. These modern PLCs facilitate real-time processing, vastly improving industrial processes by reducing human error and enhancing reliability. As a result, industries could adopt more sophisticated control logic while adapting to evolving manufacturing demands. When selecting PLC brands for industrial automation, leading names such as Siemens, Allen-Bradley (Rockwell Automation), Mitsubishi Electric, Schneider Electric, and Omron are frequently considered the best due to their reliability, scalability, software support, and global availability. Key factors to consider when choosing a PLC include the required input/output capacity, communication protocols, integration with existing systems, vendor support, programming environment, and the specific demands of the industrial application.

Key Milestones in PLC Development

Significant milestones have shaped the evolution of programmable logic controllers (PLCs), transforming industrial automation. The late 1960s marked the advent of the first PLC, designed to replace complex relay logic systems. In the 1980s, the introduction of modular PLCs enhanced flexibility, allowing for tailored configurations to meet diverse industrial needs. The rise of open standards in the 1990s facilitated interoperability between different control systems, while advancements in communication technology paved the way for integration with SCADA systems and the Industrial Internet of Things, making modern PLCs indispensable in automated processes.

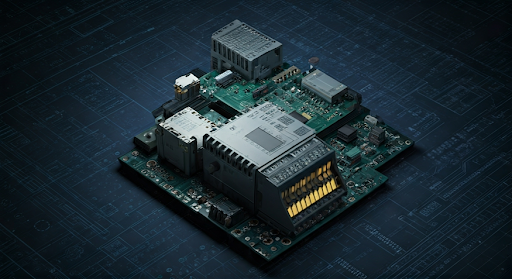

Understanding PLC Architecture and Components

Central to the functionality of a programmable logic controller (PLC) are its core hardware elements, which include the processor, memory, and input/output (I/O) modules. This architecture enables real-time data acquisition and precise control over industrial processes. Different types of PLCs—ranging from fixed to modular and distributed configurations—offer versatility across various industrial environments. Such adaptability is essential for tasks that require specific input devices and output signals, addressing the diverse needs of manufacturing and automation systems.

Core Hardware Elements of a PLC System

A programmable logic controller consists of several essential hardware components that work together to ensure efficient operation within industrial environments. The central processing unit (CPU) executes control logic and processes input signals, while input devices gather data from the field, such as sensors and switches. Output interfaces connect to automation systems, activating output devices like motors and actuators. Memory stores the program and data, supporting real-time operations, while communication ports facilitate interaction with supervisory control and data acquisition (SCADA) systems and human-machine interfaces (HMIs).

Types of PLCs: Fixed, Modular, and Distributed

Several types of programmable logic controllers exist, catering to diverse industrial needs. Fixed PLCs offer a compact solution typically suited for simple, dedicated tasks in smaller automation systems. On the other hand, modular PLCs provide flexibility, allowing for the addition of extra modules as requirements evolve. Distributed PLCs enhance system scalability by decentralizing control, which is particularly advantageous in complex manufacturing processes. Each type serves a unique purpose, ensuring efficient operation and optimal performance within industrial environments.

How PLCs Operate in Automated Environments

In automated environments, the operation of programmable logic controllers (PLCs) hinges on an efficient scan cycle composed of input, processing, and output stages. This continuous loop facilitates real-time interactions with input devices, translating data into actionable control logic. Moreover, advanced communication protocols enable seamless integration with supervisory control and data acquisition (SCADA) systems. As PLCs manage output signals to connected devices, they enhance operational efficiency across diverse industrial processes, making them vital for modern manufacturing and automation systems.

The Scan Cycle: Input, Processing, and Output

Each scan cycle in a programmable logic controller (PLC) system comprises three essential phases: input, processing, and output. During the input phase, data is gathered from various input devices, such as sensors, which capture real-time information about the industrial environment. Following this, the processing phase interprets the control logic, incorporating programmed instructions and making decisions based on the received inputs. Finally, the output phase activates connected output devices, transforming the processing results into actions that drive automation within manufacturing processes and other industrial applications.

Real-Time Communication and Interface Integration

Each scan cycle in a programmable logic controller (PLC) system comprises three essential phases: input, processing, and output. During the input phase, data is gathered from various input devices, such as sensors, which capture real-time information about the industrial environment. Following this, the processing phase interprets the control logic, incorporating programmed instructions and making decisions based on the received inputs. Finally, the output phase activates connected output devices, transforming the processing results into actions that drive automation within manufacturing processes and other industrial applications.

Real-Time Communication and Interface Integration

Real-time communication is essential for efficient industrial automation systems. Through robust protocols, PLCs enable seamless data exchange between input devices, sensors, and output devices, ensuring swift decision-making. Integration with SCADA systems enhances monitoring capabilities, allowing for immediate responses to operational changes. This connectivity fosters improved control logic and predictive maintenance, reducing human error. With advancements in IoT technologies, PLCs can interact with remote locations, optimizing overall system performance and providing valuable insights into manufacturing processes and industrial environments.

Advantages of Using PLCs Over Traditional Control Systems

Flexibility and scalability are standout features of programmable logic controllers, making them a superior choice in modern industrial environments. Unlike traditional control systems, PLCs can be easily reprogrammed and expanded to accommodate evolving manufacturing processes. Enhanced diagnostics and safety features further ensure reliability, minimizing human error during operations. With capabilities like real-time communication and seamless integration with SCADA systems, PLCs empower industries to optimize production efficiency, effectively adapt to extreme temperatures, and maintain stringent industry standards, driving innovation forward.

Flexibility, Scalability, and Precision

Tailoring automation systems to various industrial processes showcases the inherent flexibility of programmable logic controllers (PLCs). Their ability to accommodate different control logic configurations allows them to adapt swiftly to changing manufacturing demands. Scalability is another significant advantage, enabling systems to expand alongside growing operational needs without significant overhauls. Furthermore, the precision offered by PLCs enhances efficiency in control tasks, minimizing human error and ensuring accurate output signals across complex processes. This trifecta positions PLCs as essential in modern industrial environments.

Enhanced Diagnostics, Safety, and Reliability

Utilizing programmable logic controllers significantly enhances diagnostics within industrial environments. With built-in self-monitoring and predictive maintenance capabilities, these systems minimize human error by promptly identifying issues before they escalate. Safety remains a paramount concern; modern PLCs incorporate advanced safety features that ensure compliance with industry standards, protecting both personnel and equipment. Additionally, their reliability under extreme temperatures and various conditions allows for uninterrupted operation. This seamless integration ultimately leads to optimized manufacturing processes and more efficient industrial automation.

Programming PLCs: Languages and Techniques

Multiple programming languages exist for programming PLCs, each catering to different applications and user preferences. Ladder logic remains the most widely used due to its intuitive design resembling electrical relay diagrams, making it accessible for many operators. Structured text offers a more complex approach, suitable for robust algorithms and data manipulation. Function block diagrams provide a visual representation, enhancing scalability and ease of use in complicated processes. Embracing simulation tools for testing and remote programming further streamlines the development process, fostering efficiency in automation systems.

Ladder Logic, Structured Text, and Other Standards

Ladder logic remains a cornerstone of PLC programming, mimicking electrical relay logic in a visually intuitive manner. This simplicity enables engineers to implement control logic swiftly. Alternatively, structured text offers a more robust coding language, ideal for complex operations and data manipulation within automation systems. Other standards, such as function block diagrams, enhance modularity and reusability in programming. Together, these programming languages and techniques provide flexibility, catering to diverse needs across manufacturing processes and ensuring efficiency in PLC applications.

Tools, Simulation, and Remote Programming

Utilizing advanced tools for PLC programming significantly enhances efficiency in managing industrial automation systems. Simulation software allows engineers to visualize control logic and forecast the impact of changes in real-time, minimizing human error during implementation. Remote programming capabilities enable seamless adjustments to PLC applications from various locations, which is crucial for maintaining optimal performance across manufacturing processes. By leveraging these tools, professionals can ensure that all components, including input devices and output signals, work in harmony within complex industrial environments.

PLCs in Action: Industrial Applications and Use Cases

PLCs play a crucial role in various industrial applications, seamlessly integrating with manufacturing processes, robotics, and process industries. In assembly lines, for instance, programmable logic controllers enhance efficiency by managing complex data from discrete inputs and controlling output devices like electric motors. Their ability to interface with SCADA systems and the Industrial Internet of Things (IIoT) enables real-time monitoring and predictive maintenance, significantly reducing human error and ensuring reliability in challenging industrial environments. This versatility makes PLCs an invaluable asset across sectors.

Applications in Manufacturing, Robotics, and Process Industries

Numerous sectors leverage programmable logic controllers for enhanced efficiency and productivity. In manufacturing, PLCs streamline assembly lines, optimizing each phase of production by managing electric motors and discrete inputs. Robotics applications benefit from real-time feedback, using sophisticated control logic to adapt to changing conditions. Process industries implement PLCs to monitor and control complex data and ensure safety, employing human machine interface (HMI) systems for intuitive user interactions. This integration fosters flexibility, paving the way for innovations in modern industrial environments.

Integration with IIoT, SCADA, and Advanced Automation Systems

Seamless integration of programmable logic controllers (PLCs) with the Industrial Internet of Things (IIoT) and SCADA systems enhances operational efficiency. By enabling real-time data acquisition and communication, this synergy allows for improved predictive maintenance and reduced human error in industrial environments. Advanced automation systems leverage PLC outputs to interface with connected output devices and user-friendly HMI systems, ensuring optimal control logic throughout manufacturing processes. As industries evolve, this integration lays a foundation for smarter, more responsive production systems.

Conclusion

The transformation within the industrial landscape is undeniable, with programmable logic controllers (PLCs) leading the charge towards enhanced efficiency and reliability. Ultimately, their capacity for real-time communication, scalability, and adaptability in various industrial environments highlights their crucial role in modern automation systems. As industries continue to evolve, the integration of PLCs alongside advancements like the Industrial Internet of Things (IIoT) propels efficiency and innovation, paving the way for smarter and more responsive manufacturing processes.

What is the use of PLC in automation industry?

PLCs, or Programmable Logic Controllers, are essential in the automation industry for controlling machinery and processes. They offer reliable, real-time processing capabilities, enabling precise control over various industrial applications. By automating repetitive tasks, PLCs enhance efficiency, reduce human error, and improve overall productivity in manufacturing environments.