Discover Siemens Programmable Logic Controller Secrets Now

Key Highlights

- Siemens SIMATIC programmable logic controllers (PLCs) are central to industrial automation, driving precision and reliability in countless sectors.

- The SIMATIC S7 family, including the S7-1200, S7-1500, S7-300, and S7-400 models, caters to every automation system requirement—from compact solutions to large-scale operations.

- Programming is streamlined using SIMATIC STEP and TIA Portal, offering intuitive interfaces for both beginners and professionals.

- Real-world automation solutions benefit from the scalability, modularity, and robust networking of Siemens SIMATIC PLCs.

- Comprehensive safety, security, and maintenance features ensure long-term uptime and data protection for automation systems.

- Siemens provides extensive support, learning resources, and integration options, making their programmable logic systems accessible and future-ready.

Introduction

Programmable logic has become the heartbeat of modern industry, and Siemens SIMATIC has set the standard for automation solutions worldwide. Whether you’re overseeing a production line or controlling infrastructure, Siemens programmable logic controllers (PLCs) provide the intelligence and flexibility to automate complex processes. This blog uncovers the secrets behind Siemens PLC programming, helping you understand how SIMATIC technology can enhance productivity, streamline control, and ensure reliability in your automation projects.

Understanding Siemens Programmable Logic Controllers (PLCs)

Siemens programmable logic controllers (PLCs) serve as the backbone of industrial automation, providing robust solutions for various automation tasks. Utilizing the Siemens SIMATIC series, these devices rely on the SIMATIC STEP programming environment within the TIA Portal framework to facilitate seamless operation and integration. The intuitive design of Siemens PLCs enables users to implement efficient programmable logic, enhancing overall productivity. By leveraging these advanced automation systems, industries can optimize processes, reduce downtime, and achieve remarkable efficiency in their operations.

What Are PLCs and Their Core Functions in Automation?

PLCs, or programmable logic controllers, are rugged computers engineered to control industrial processes by monitoring inputs and managing outputs. Imagine a PLC as the central decision-maker in an automation system—it reads data from sensors, processes that information according to a program, and instructs machines or actuators on what to do next.

For someone new to industrial automation, a Siemens PLC might appear complex, but its operation is straightforward at its core. The PLC continually cycles through scanning inputs, executing programmed instructions, and updating outputs. This rapid, repetitive process enables precise, real-time control in factories, infrastructure, and beyond.

Siemens SIMATIC PLCs stand out for their flexibility, allowing users to modify control strategies, expand systems, and respond to new requirements without major rewiring or hardware changes. This adaptability makes programmable logic essential for modern industrial automation.

Real-World Applications and Examples of Siemens PLCs

In practice, Siemens SIMATIC programmable logic controllers are at work across a broad spectrum of industries, powering everything from manufacturing plants to critical infrastructure. Their reliability and adaptability have made them a favorite in automation solutions worldwide.

Examples of Siemens PLC applications include:

- Managing conveyor systems, robotic arms, and packaging lines in manufacturing facilities.

- Overseeing water treatment operations, ensuring optimal flow and chemical dosing.

- Controlling building automation systems for lighting, HVAC, and security in large structures.

Their use extends to power generation, food processing, and transportation, where programmable logic guarantees safety, efficiency, and repeatability. As technology advances, the scope of Siemens PLCs continues to broaden, providing automation solutions for both established industries and emerging markets.

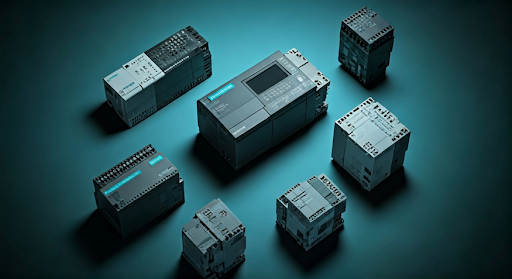

The Siemens SIMATIC PLC Family Explained

The Siemens SIMATIC family represents a comprehensive lineup of programmable logic controllers, each tailored for specific automation system needs. From entry-level to high-performance models, SIMATIC offers flexibility, scalability, and seamless integration into complex industrial environments.

Compared to other brands, Siemens SIMATIC PLCs stand out for their robust design, extensive module choices, and straightforward programming interfaces. These features make SIMATIC a trusted choice for businesses seeking reliable automation solutions that can grow with changing requirements.

Key Models: S7-1200, S7-1500, S7-300, and S7-400

The core of the SIMATIC programmable logic family includes four key models: S7-1200, S7-1500, S7-300, and S7-400. Each is designed to match specific performance and application needs, ensuring there’s a SIMATIC PLC for every automation scenario.

The S7-1200 is ideal for compact systems and smaller projects, while the S7-1500 steps up to high-end performance, handling complex automation and fast data processing. The S7-300 is renowned for its modularity and reliability in versatile environments, and the S7-400 excels in large-scale, mission-critical operations.

| PLC Model | Performance | Size | Applications |

|---|---|---|---|

| S7-1200 | Entry-Level | Compact | Small to medium automation projects |

| S7-1500 | High-End | Compact/Mid-Size | Large-scale manufacturing, process automation |

| S7-300 | Versatile | Modular | Manufacturing, infrastructure, adaptable systems |

| S7-400 | Maximum Flexibility | Large | Heavy industry, process automation, high I/O |

Features That Differentiate SIMATIC PLCs from Other Brands

SIMATIC PLCs deliver features that set them apart in the industrial automation landscape. Their modular architecture, extensive communication options, and seamless integration with other Siemens automation solutions are key advantages.

Key differentiators include:

- Advanced diagnostics and maintenance features for proactive system monitoring.

- Flexible module expansion and compatibility with distributed I/O, allowing for customized automation solutions.

- Built-in security and safety functions, ensuring reliable and protected operation in demanding environments.

Compared to other brands, SIMATIC PLCs are celebrated for their long-term reliability and robust support ecosystem. As Peter Löscher, former CEO of Siemens AG, noted: “Innovation and quality are at the heart of every SIMATIC system, empowering industries to run safely and efficiently.” This reputation ensures Siemens remains a top choice for automation professionals worldwide.

Software & Tools for Programming Siemens PLCs

Programming Siemens SIMATIC PLCs requires specialized software that brings hardware and logic together for seamless automation. SIMATIC STEP and TIA Portal are the industry standards, offering user-friendly environments for configuring, coding, and commissioning controllers.

These platforms support multiple programming languages—such as Ladder Diagram, Function Block Diagram, and Structured Text—giving users the flexibility to choose the approach that best fits their experience and application. With strong integration features, you can efficiently manage engineering tasks and streamline your entire automation workflow.

TIA Portal and Classic STEP 7 Overview

TIA Portal (Totally Integrated Automation Portal) is Siemens’ unified software environment, designed to simplify every aspect of programmable logic development. It integrates configuration, programming, diagnostics, and commissioning into a single, intuitive platform.

Classic STEP 7 remains a popular choice for programming legacy SIMATIC S7-300 and S7-400 controllers. Both TIA Portal and STEP 7 support multiple programming languages, including Ladder Diagram (LAD), Function Block Diagram (FBD), and Structured Text (SCL), accommodating users with different backgrounds and preferences.

The result is a programming ecosystem that enhances productivity, supports code reusability, and ensures your automation system is scalable and easy to maintain. Whether you’re starting with a compact S7-1200 or managing a complex S7-1500 installation, Siemens’ software options adapt to your needs.

Integration of Software with Siemens PLC Hardware

Seamlessly connecting programming software to Siemens SIMATIC hardware is pivotal in building an effective automation system. TIA Portal and STEP 7 are designed to interface directly with controllers, enabling quick hardware detection, configuration, and program downloading.

The process begins with setting up your hardware topology in the software, which mirrors your real-world automation system. Once configured, you can develop logic, test functions, and simulate processes before deployment—reducing costly errors and engineering time.

With built-in diagnostics and monitoring, the software also allows you to troubleshoot, update programs, and manage connectivity over Industrial Ethernet or Profinet. This tight integration ensures your automation solutions operate reliably and can be easily modified as your requirements evolve.

Step-by-Step Guide to Setting Up and Commissioning a Siemens PLC

Getting started with Siemens SIMATIC PLCs is straightforward, thanks to a clear setup process and comprehensive software support. Setting up a basic automation system involves connecting hardware components, configuring devices, and programming your first logic sequence.

Using tools like TIA Portal and SIMATIC STEP, you can quickly integrate your PLC with sensors, actuators, and networked devices, then test and deploy your automation solution with confidence. The following sections break down the setup into manageable steps for both hardware and programming.

Hardware Connections and Initial Configuration

Begin by assembling your automation system hardware, which includes the Siemens SIMATIC PLC, power supply, input/output modules, and necessary communication interfaces. Secure all modules onto the DIN rail and connect them using Siemens’ recommended wiring practices.

Key steps for hardware setup:

- Attach the CPU and connect input/output modules according to your system requirements.

- Link sensors, actuators, and power supply as specified in the PLC documentation.

- Connect the PLC to your PC or engineering workstation via Ethernet or USB for further configuration.

Once physically connected, power up the system and use TIA Portal or STEP 7 to detect devices, assign addresses, and verify communication. This initial setup ensures your PLC is ready for programming and integration with the rest of your automation solution.

Programming Your First Automation Task

With the hardware in place, it’s time to program your first automation sequence. Open TIA Portal or SIMATIC STEP and start a new project, selecting your PLC model and configuring basic parameters.

Follow these programming steps:

- Define I/O addresses and create logic using Ladder Diagram, Function Block Diagram, or Structured Text.

- Simulate and test your program within the software environment before downloading it to the PLC.

- Download the tested program to the PLC and monitor real-time operation using built-in diagnostic tools.

By following these steps, even beginners can commission a Siemens programmable logic controller for tasks such as controlling a motor, monitoring sensors, or managing a simple production sequence. Siemens’ tools make it easy to adjust, expand, or troubleshoot your automation solution as your needs change.

Safety, Security, and Maintenance Essentials for Siemens PLCs

Safety and security are critical in any automation system, and Siemens programmable logic controllers are designed with robust protections to safeguard operations and data. These built-in features help prevent unauthorized access, reduce risks, and support compliance with industry standards.

Regular maintenance and effective troubleshooting ensure that your Siemens automation solutions deliver high reliability and uptime. With powerful diagnostic tools and preventive strategies, you can quickly address issues, minimizing downtime and keeping your automation system running smoothly.

Built-In Safety Measures and Cybersecurity Features

Siemens SIMATIC PLCs incorporate several layers of safety and cybersecurity to protect industrial automation environments. These measures help prevent accidents, data breaches, and unauthorized interventions within your automation solution.

Key safety and security features include:

- Integrated safety CPUs and modules that support fail-safe operations and emergency stop functions.

- Role-based access control and encrypted communication to protect against cyber threats.

- Diagnostic and alarm systems that alert users to irregularities in real time.

These protections not only ensure the physical safety of personnel and equipment but also safeguard sensitive data and prevent malicious attacks. “Security is not a product, but a process,” said Bruce Schneier, security technologist, emphasizing the importance of ongoing vigilance. Siemens’ programmable logic systems provide the foundation for secure, dependable automation.

Troubleshooting and Preventive Maintenance Strategies

Reliability in industrial automation depends on systematic troubleshooting and scheduled maintenance. Siemens PLCs are equipped with diagnostic tools and maintenance features that enable you to spot issues early and keep your system operating at peak performance.

Effective strategies include:

- Utilizing software diagnostics in TIA Portal or STEP 7 to identify and resolve faults quickly.

- Regularly updating firmware and software to address potential vulnerabilities or improve stability.

- Scheduling preventive maintenance, such as checking wiring, cleaning modules, and verifying backups.

By integrating these practices into your automation system routine, you can reduce unplanned downtime, extend equipment lifespan, and ensure consistent, reliable operation. Siemens’ focus on maintainability makes it easier for operators and engineers to support long-term productivity in any industrial setting.

Conclusion

In summary, understanding and mastering Siemens PLC programming can significantly enhance your automation projects. With a comprehensive grasp of the various models, software tools, and essential safety measures, you’re well on your way to optimizing processes in diverse industries. The insights shared here not only demystify the complexities of Siemens PLCs but also encourage a methodical approach to programming and maintenance. Whether you're a beginner eager to learn or a seasoned pro seeking to refine your skills, embracing these principles will undoubtedly lead to greater efficiency and success in your endeavors. For personalized guidance, feel free to reach out for a consultation.

Frequently Asked Questions

Are Siemens PLCs suitable for beginners and what learning resources are available?

Absolutely. Siemens SIMATIC programmable logic controllers are ideal for beginners, especially the S7-1200 series. Siemens offers a wealth of learning resources, including TIA Portal tutorials, SIMATIC STEP guides, and hands-on training modules, making it easier for newcomers to master industrial automation.

Which industries most commonly use Siemens programmable logic controllers?

Siemens SIMATIC programmable logic controllers are widely deployed across manufacturing, energy, water treatment, infrastructure, and food processing sectors. Their flexibility and reliability make them the preferred choice for controlling automation systems and delivering tailored automation solutions in diverse industrial environments.

How reliable are Siemens PLCs compared to other automation brands?

Siemens SIMATIC programmable logic controllers are renowned for their exceptional reliability and robustness in industrial automation. Their advanced automation solutions, extensive diagnostics, and strong global support ensure they match or exceed the standards of other leading automation system brands.