Understanding PLC Programmable Logic Controller Basics

Key Highlights

- Programmable logic controllers (PLCs) are industrial computer control systems that automate processes using custom program logic and a variety of input/output modules.

- Widely used in industrial automation, PLCs manage machinery, monitor equipment status, and ensure real-time system safety and reliability.

- Ladder logic is the most common programming language for PLCs, but function block diagrams and structured text are also used. PLCs can be integrated with SCADA systems and Human Machine Interfaces (HMIs) for advanced monitoring and control. PLCs are commonly used in industries such as manufacturing, automotive, food and beverage, oil and gas, water treatment, and pharmaceuticals. They are essential for automating processes like assembly lines, packaging systems, batch processing, and quality control.

- PLCs can be integrated with SCADA systems and Human Machine Interfaces (HMIs) for advanced monitoring and control.

- Common applications include manufacturing, energy, transportation, and water treatment, with Siemens, Allen Bradley, and Omron as leading brands.

- PLCs are highly adaptable, durable, and support both analog and digital control, making them vital in modern automation.

Introduction

Understanding the intricate world of programmable logic controllers (PLCs) sets the stage for mastering industrial automation. These versatile devices act as the backbone of modern manufacturing, enabling seamless communication and precise control over various processes. With the implementation of programming languages like ladder logic, users can customize operations to meet specific machine functions. As we explore the components, types, and programming basics, a clearer picture of how PLCs fit into the industrial internet of things (IIoT) will emerge, paving the way for increased efficiency and productivity.

What Is a PLC and How Does It Work?

A Programmable Logic Controller (PLC) is an industrial digital computer used for automation of electromechanical processes. It works by receiving input signals, processing them based on a program, and sending output signals to control machinery, ensuring efficient and reliable operation in various applications.

Understanding the Basic Definition of Programmable Logic Controllers

Programmable logic controllers (PLCs) serve as integral components in industrial automation, functioning as specialized industrial computer control systems. Acting on the state of input devices, PLCs process data through custom programs, allowing for precise control over outputs. Utilizing various programming languages, including ladder logic, they facilitate seamless interaction with additional hardware and sensors. This flexibility enables real-time management of machine functions and supervisory control over processes, solidifying PLCs as a cornerstone of efficient automation in modern industries.

Key Differences Between PLCs, Relay Logic, and DCS Systems

Programmable logic controllers (PLCs), relay logic, and distributed control systems (DCS) each serve distinct roles in industrial automation. While relay logic relies on physical relays for control, limiting complexity and scalability, PLCs use programmable logic to manage diverse inputs and outputs, adapting to real-time changes. In contrast, DCS systems excel in overseeing large processes via centralized supervisory control and data acquisition, providing advanced monitoring. The choice among these systems often hinges on application requirements, complexity, and integration with additional hardware.

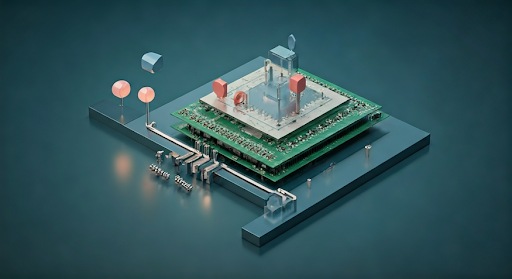

Main Components and Architecture of PLC Systems

Central to a PLC's functionality are its main components, which include the Central Processing Unit (CPU), power supply, and memory. The CPU processes programming languages, executing a custom program that manages outputs and inputs in real time. Additionally, input/output modules facilitate communication with various sensors and output devices. Together, these elements form an efficient architecture, allowing the programmable logic controller to seamlessly integrate with an industrial computer control system, enhancing automation and supervisory control for streamlined operations.

Central Processing Unit (CPU), Power Supply, and Memory

In a PLC system, the central processing unit (CPU) serves as the brain, executing custom programs to control machine functions in real-time. It processes signals from input devices, determining the state of all input devices and consequently managing output devices. Complementing the CPU, the power supply ensures uninterrupted operation, supplying energy to modules and additional hardware. Memory is crucial, facilitating data storage and retrieval necessary for programming languages like ladder logic while supporting the industrial automation landscape by maintaining essential operational parameters.

Input/Output Modules and Communication Interfaces

Input/output modules serve as critical components in the functionality of programmable logic controllers. These modules facilitate the connection between the PLC and various sensors and output devices, ensuring seamless data transfer. Communication interfaces play a pivotal role as well, enabling real-time interaction with supervisory control and data acquisition systems. By utilizing both analog and digital signals, these interfaces enhance an industrial automation system's responsiveness and reliability, thus supporting efficient operations and enabling integration with the industrial internet of things (IIoT) for advanced monitoring and control.

Types of PLCs Used in Industrial Automation

Several types of PLCs play a crucial role in industrial automation, each tailored to specific applications. Fixed PLCs offer a compact design with predetermined inputs and outputs, ideal for straightforward control tasks. On the other hand, modular PLCs allow for greater flexibility, enabling the addition of various modules catering to a diverse range of sensors and output devices. This adaptability proves essential for complex industrial environments, enhancing real-time data acquisition and supervisory control within the broader framework of the Industrial Internet of Things (IIoT).

Fixed vs Modular PLCs: Features and Applications

Fixed PLCs are compact systems designed for specific applications, offering simplicity and efficiency. Their architecture typically restricts expansion, making them ideal for smaller tasks with a limited number of inputs and outputs. In contrast, modular PLCs feature interchangeable components that allow for greater flexibility and scalability. This adaptability supports complex industrial automation setups, accommodating varied programming languages and additional hardware like sensors and IOT devices. Modular PLCs are optimal for environments where system demands can evolve, ensuring continuous performance in real-time operations.

Popular PLC Brands and Their Unique Characteristics

Several PLC brands stand out in the realm of industrial automation, each bringing unique features to the table. Before exploring the unique characteristics of these brands, it is important to understand the basic components and architecture of a typical PLC system. A PLC system generally consists of a central processing unit (CPU), input/output (I/O) modules, a power supply, and a programming device. The CPU handles program execution and decision-making, while input modules receive signals from sensors and output modules send commands to actuators. The power supply provides necessary electric power, and the programming device is used for configuring and troubleshooting the PLC. For instance, Siemens is renowned for its robust HMI capabilities and seamless integration with SCADA systems. Allen-Bradley, on the other hand, excels in custom programming options and a user-friendly interface. Mitsubishi emphasizes compact design without compromising power, making it ideal for space-constrained applications. Lastly, Schneider Electric's focus on the Industrial Internet of Things (IIoT) enhances connectivity and real-time monitoring across various modules.

PLC Programming Basics and Common Languages

Various programming languages facilitate effective communication between users and programmable logic controllers. Ladder logic, widely adopted in industrial automation, mimics relay logic and illustrates the state of input devices alongside output devices. Function block diagrams offer a graphical approach, simplifying the representation of complex operations. Structured text, akin to high-level programming languages, allows for custom program development. Each of these languages plays a crucial role in programming the function and behavior of PLCs, ensuring real-time control over industrial processes.

Ladder Logic, Function Block Diagram, and Structured Text Explained

Ladder logic serves as a visual representation of program sequences, mimicking electrical relay logic. Utilizing rungs and symbols, it simplifies the programming process, making it intuitive for operators familiar with circuit diagrams. Function block diagrams offer a more graphical approach, enabling modular programming by connecting functional blocks. Meanwhile, structured text employs a high-level programming language, allowing for complex algorithms. Together, these programming languages enhance the functionality and flexibility of programmable logic controllers, ensuring efficient industrial automation.

Conclusion

In summary, mastering the intricacies of PLC programming is essential for anyone involved in industrial automation. Understanding how these versatile systems operate empowers users to optimize machine functions efficiently. Furthermore, familiarity with various programming languages, such as ladder logic and structured text, as well as integrating components like CPUs and I/O modules, enhances the overall effectiveness. Embracing these principles not only streamlines operations but also prepares individuals for the evolving landscape of the Industrial Internet of Things and advanced automation technologies. PLCs are commonly used across various industries such as manufacturing, automotive, food and beverage, pharmaceutical, and water treatment. Typical processes where PLCs are integral include assembly lines, conveyor systems, machine control, packaging, and process monitoring, making them a cornerstone in modern industrial environments.