Unlock the Benefits of Automation in Your Life

Unlock the Benefits of Automation in Your Life

Key Highlights

Here are the main takeaways from our guide to understanding automation:

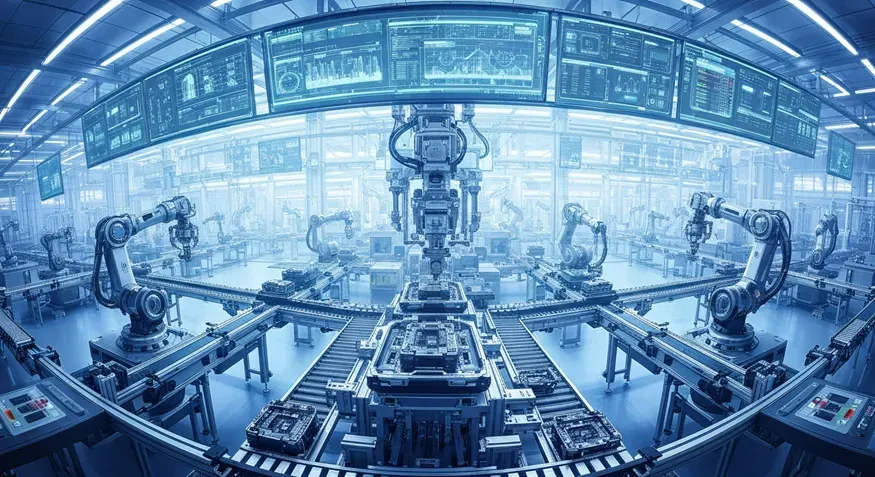

- Automation uses technology to perform tasks with minimal human intervention, boosting efficiency in various industries.

- The main types of automation include fixed, programmable, flexible, and integrated systems, each serving different production needs.

- Industrial automation offers significant benefits like increased productivity, improved safety for human workers, and higher product quality.

- Artificial intelligence is a key driver of modern automation solutions, enabling machines to learn, adapt, and make decisions.

- While automation presents challenges like initial costs, it also creates new opportunities for employees who develop technical and problem-solving skills.

- From industrial robotics to smart home devices, process automation is reshaping both our workplaces and our daily lives.

Introduction

Have you ever wondered how your favorite products are made so quickly and consistently? The answer often lies in automation. Far from being a futuristic idea, automation is a present-day reality that is transforming various industries. From the factory floor to your smartphone, automation solutions are reshaping the production process and changing how businesses operate. This guide will walk you through what automation is, how it works, and the incredible benefits it offers to businesses and individuals alike.

Defining Automation and Its Relevance Today

At its core, automation is about using technology to get things done with less human intervention. It involves integrating systems and machinery to handle tasks that were once performed by human workers. This shift allows people to focus on more creative and strategic work.

Today, industrial automation is more relevant than ever. In a competitive global market, businesses rely on automation solutions to enhance efficiency, ensure precision, and stay ahead. Understanding the fundamentals of automation is the first step toward appreciating its widespread impact. Let's explore what automation is and why it has become so crucial.

What Is Automation?

So, what exactly is automation? Simply put, automation is the use of technology to perform tasks that once required human intervention. It's a strategic approach where computer systems, robotics, and machinery are integrated to refine and streamline a production process. The goal is to make operations more efficient, precise, and reliable.

This technological upgrade isn't about replacing people but rather shifting human workers to more valuable and less repetitive work. Think of industrial automation as a tool that enhances human capabilities. By handling mundane or hazardous tasks, automation frees up employees to focus on problem-solving, innovation, and other areas where human creativity shines.

Ultimately, automation solutions encompass a wide range of applications, from managing inventory to ensuring quality control. While often associated with manufacturing, the principles of automation extend to virtually

every industry, optimizing processes far beyond the factory floor.

Importance of Automation in Modern Industries

Why has industrial automation become such a big deal? In today's fast-paced world, companies need every competitive advantage they can get. Automation provides just that by revolutionizing how industries operate. It allows businesses to optimize production, improve safety, and reduce operational costs.

Implementing automation is crucial for maintaining high standards of quality control. Machines can perform tasks with a level of precision and consistency that is difficult for human workers to sustain over long periods. This reliability ensures that every product meets the same high standard, boosting customer satisfaction and brand reputation.

Furthermore, automation empowers companies to set new industry benchmarks. By streamlining processes and reallocating human workers to higher-value roles, businesses can innovate faster and adapt more quickly to market changes. This strategic edge is why automation is no longer an option but a necessity for modern industries aiming for growth and resilience.

Brief History and Evolution of Automation

The concept of automation isn't new. Its roots can be traced back to the industrial revolution, which introduced basic mechanization to the manufacturing process. However, early forms of automation were simple and focused on single, repetitive tasks. Over the decades, these systems have evolved into something far more sophisticated.

A significant leap forward came with the development of numerical control (NC) machines, which used programmed instructions to guide tools. This paved the way for more complex and flexible automation. As technology advanced, industrial automation technology began incorporating computers, leading to more comprehensive and integrated systems.

Today, we are in an era of advanced automation, often referred to as Industry 4.0. What started as simple machinery has transformed into intelligent systems that can oversee an entire production line. This evolution shows a clear trajectory from basic task automation to the smart, interconnected factories we see today.

Types of Automation Systems

Not all automation is the same. Depending on the industry and specific needs, businesses can implement different types of automation systems. Understanding each type of automation is key to selecting the right solution for your unique production requirements and goals.

From rigid systems designed for mass production to highly adaptable ones for custom orders, there is an automation system for nearly every scenario. The main categories include fixed, programmable, flexible, and integrated automation. Let’s look at the characteristics and applications of each to see how they fit into the modern industrial landscape.

Fixed Automation: Characteristics and Applications

Fixed automation, sometimes called "hard automation," is the oldest and most rigid form of automation technology. It involves using specialized equipment designed to perform a specific set of repetitive tasks without variation. These systems are built for a single purpose and cannot be easily reprogrammed to do something else.

Because they are dedicated to one job, fixed automation systems are incredibly fast and efficient. This makes them ideal for mass production environments where the same operation is performed over and over again. You can often see this type of automation in action on automotive assembly lines, where machines are set up to weld, paint, or assemble a specific part.

The primary advantage of fixed automation is its high production rate. However, its major limitation is its lack of flexibility. If the product design changes, the entire system might need to be re-engineered, which can be costly and time-consuming.

Programmable Automation for Flexible Production

Programmable automation offers more flexibility compared to its fixed counterpart. This type of automation uses computer-controlled machines that can be reprogrammed to perform a range of different tasks. Instead of being locked into one function, the equipment's operations can be altered by changing the software instructions.

A key component of programmable automation is the use of Programmable Logic Controllers (PLCs). These devices allow operators to program and control various automated processes on production lines. This makes the system ideal for industries that produce goods in batches, where different products or models are manufactured on the same equipment.

Compared to flexible automation, programmable systems are well-suited for low-volume, high-variety production. For example, a CNC machine can be programmed to produce different parts simply by loading new instructions. This adaptability allows businesses to switch between products without needing to completely overhaul their machinery.

Integrated Automation in Complex Environments

At the highest level of complexity is integrated automation. This approach combines multiple types of automation systems—including fixed, programmable, and flexible—to create a single, unified production process. It represents a comprehensive strategy where the entire factory is managed as one cohesive system.

Integrated automation relies on advanced computer software to coordinate the activities of all automated components, from robots and conveyors to sensors and other industrial processes. This creates a fully intelligent manufacturing ecosystem capable of handling highly complex processes with minimal human oversight. Examples include computer-integrated manufacturing (CIM) systems and modern "smart factories."

These advanced automation solutions deliver unparalleled efficiency, quality control, and adaptability. Businesses that adopt integrated automation can respond quickly to changing market demands and optimize their entire operation, from initial design to final packaging and distribution.

Emerging Trends: AI-Driven Automation Solutions

One of the most exciting developments in automation is the integration of artificial intelligence (AI) and machine learning (ML). This has given rise to intelligent automation, a new breed of automation solutions that can think, learn, and adapt on their own. Instead of just following pre-programmed instructions, these systems can analyze data and make decisions.

AI-driven automation is transforming what's possible in nearly every industry. For example, AI algorithms can help autonomous vehicles navigate dynamic environments, optimize production schedules in real-time, or predict when a machine needs maintenance before it breaks down. This level of intelligence brings greater accuracy and efficiency to complex problems.

The synergy between artificial intelligence and automation is creating systems that are more powerful and capable than ever before. As this trend continues, we can expect to see intelligent automation play an even larger role in solving some of the biggest challenges in manufacturing and beyond.

Key Technologies Powering Automation

Modern automation isn't powered by a single technology but by a combination of several innovative fields. These key technologies work together to create the intelligent and efficient systems that are reshaping industries. From physical machines to the software that controls them, each component plays a vital role.

The core technologies driving automation today include robotics, artificial intelligence and machine learning, advanced sensor technology, and sophisticated software solutions. Together, they form the backbone of automated systems, enabling them to perform complex tasks with precision and reliability. Let’s explore how each of these technologies contributes to the power of automation.

Robotics in Industrial and Commercial Settings

Robotics is one of the most visible components of industrial automation. Industrial robots have become essential assets in modern manufacturing, handling tasks that are repetitive, hazardous, or require a high degree of precision. These automated machines come in various forms, each designed for specific functions.

Common types of industrial robots include articulated robots, which have a human-like arm structure for tasks like welding and assembly. SCARA robots excel in high-speed, precise applications, such as in electronics manufacturing. Delta robots, with their three-armed design, are perfect for rapid pick-and-place operations in the food and packaging industries.

Beyond stationary robots, mobile robotic systems like Automated Guided Vehicles (AGVs) are also crucial. These driverless vehicles navigate factory floors to transport goods, streamlining material handling and improving logistical workflows. All these robotic systems are fundamental to creating an efficient and safe automated environment.

Machine Learning and Artificial Intelligence Integration

The integration of machine learning and artificial intelligence is what gives modern automation its "smarts." These technologies allow automated systems to move beyond simple, repetitive actions and perform tasks that require decision-making and adaptation. AI and ML algorithms enable machines to learn from data, recognize patterns, and improve their performance over time.

This capability is a game-changer for operational efficiency. For instance, AI can analyze vast amounts of data from production lines to identify bottlenecks or predict equipment failures. This form of data analytics helps companies optimize schedules, reduce downtime, and maintain a smooth workflow.

By embedding artificial intelligence into automation, businesses can tackle more complex problems with greater accuracy. This synergy allows systems to handle dynamic environments and unexpected situations, making automation more robust and versatile than ever before.

Sensor Technology for Automated Processes

Sensor technology acts as the eyes and ears of an automated system. Sensors collect data from the physical world and convert it into signals that machinery can understand and act upon. Without them, an automated system would be blind to its surroundings and unable to respond to changes.

These devices are crucial for everything from quality control to safety. For example, a sensor might detect if a part is correctly positioned on an assembly line or measure the temperature in a chemical process. This real-time feedback allows the system to make adjustments on the fly, ensuring consistency and preventing errors.

The rise of the Internet of Things (IoT) and the Industrial Internet of Things (IIoT) has made sensor technology even more powerful. By connecting sensors across a network, companies can gather and analyze data from every corner of their operation, leading to smarter decisions and more efficient processes.

Software Solutions for Process Automation

While hardware like robots and sensors is essential, software solutions are the brains behind process automation. These programs coordinate and manage the workflows that drive automated tasks. This is especially true for business process automation (BPA), which focuses on streamlining administrative and office-based tasks.

Business process management (BPM) software helps organizations map out, analyze, and optimize their workflows. Once a process is defined, automation software can take over, handling tasks like data entry, report generation, and customer communications. This frees up employees from tedious administrative work and reduces the chance of human error.

These software solutions are not just for the office; they also play a crucial role in industrial settings by managing production schedules, tracking inventory, and coordinating robotic systems. Ultimately, these tools provide the control and intelligence needed to make process automation work effectively.

How Automation Works in Manufacturing

Nowhere is the impact of automation more visible than in manufacturing. Industrial automation has completely transformed the modern factory, turning the production process into a highly efficient and precise operation. By integrating machinery and smart systems, manufacturers can produce goods faster and more consistently.

The core idea is to streamline every step of the manufacturing process, from handling raw materials to assembling the final product. This reduces the reliance on manual human labor for repetitive or physically demanding tasks, allowing workers to oversee the systems and handle more complex responsibilities. Let's take a closer look at how automation works on the factory floor.

Process Automation Workflow Explained

A process automation workflow is a series of steps designed to complete a task with minimal human input. It begins with defining the sequence of actions required for a specific industrial process. This could be anything from assembling a product to packaging it for shipment.

Once the workflow is mapped out, automated systems are programmed to execute each step. On production lines, this might involve robots picking up parts, machines performing a specific function like welding or painting, and conveyor belts moving the item to the next station. Sensors along the way monitor progress and provide feedback to a central control system.

This control system acts as the conductor, ensuring all the different parts of the workflow are synchronized. It manages the timing and coordination of all industrial processes, making adjustments as needed based on the sensor data. This systematic approach ensures the entire operation runs smoothly and efficiently from start to finish.

Examples of Automation on the Production Line

To better understand how automation works in practice, let's look at some common examples you might find on modern production lines. These applications showcase how different technologies come together to streamline the manufacturing process.

Many factories use industrial robots for assembly tasks. These robots can handle small, delicate components with incredible precision, ensuring every product is put together correctly. Another common example is the use of CNC machines. These automated tools can take raw materials like metal or wood and carve them into intricate parts based on a digital design.

Here are a few more specific examples:

- Automated Guided Vehicles (AGVs) navigate factory floors to transport materials between workstations, eliminating the need for manual transport.

- Conveyor systems with computer vision automatically sort and route products to the correct packaging stations.

- Robotic arms perform welding or painting tasks with consistent quality, improving the final product's finish.

Improving Efficiency and Reducing Manual Labor

One of the primary goals of industrial automation is to boost operational efficiency. Automated systems can work around the clock without getting tired or making mistakes due to fatigue. This continuous operation dramatically increases output and allows companies to meet high demand more effectively.

By taking over repetitive and physically strenuous tasks, automation significantly reduces the need for manual labor in certain roles. This shift doesn't just lead to lower costs associated with labor; it also improves workplace safety by removing people from potentially hazardous situations.

The result is a more streamlined and productive operation. With fewer errors and less downtime, companies can optimize their resource usage and achieve significant gains in efficiency. This allows them to produce more goods at a higher quality while maintaining a competitive edge in the market.

Everyday Life: Examples of Automation

Automation isn't just for factories and large-scale industries. You might be surprised to learn how much you interact with automation solutions in your daily life. The use of technology to simplify tasks has moved from the industrial world into our homes, cars, and even our shopping experiences.

From smart home devices that adjust your thermostat automatically to automated customer service chatbots that answer your questions online, automation is all around us. These everyday examples show how the same principles that drive industrial efficiency can also bring convenience and simplicity to our personal lives.

Smart Home Devices and Personal Technology

Your home is likely filled with examples of automation. Smart home devices are a prime example of how personal technology uses automation to make life easier. These devices are often connected through the Internet of Things (IoT), allowing them to communicate with each other and perform tasks without your direct command.

For instance, a smart thermostat can learn your daily routine and adjust the temperature automatically to save energy. A robotic vacuum can clean your floors on a set schedule, and smart lighting can turn on and off as you enter or leave a room. These are all simple but powerful automation solutions.

Here are a few more examples of automation in personal technology:

- Voice assistants like Alexa or Google Assistant can control various devices, play music, or set reminders based on your verbal commands.

- Smart security cameras can detect motion and send an alert to your phone automatically.

- Automated sprinkler systems can water your lawn based on weather forecasts.

Self-Service Kiosks and Online Services

Have you ever used a self-checkout at the grocery store or ordered food from a touchscreen kiosk? These are examples of self-service kiosks, a form of automation designed to improve customer service and efficiency. They allow you to complete transactions quickly without needing to wait for a cashier.

This type of automation extends to many online services as well. When you interact with a customer service chatbot to resolve an issue or use an automated system to book a flight, you are benefiting from automation. These systems can handle common requests and provide information 24/7, offering a level of convenience that would be impossible with human agents alone.

The benefits of automation in these contexts are clear: faster service for you and lower operational costs for the business. It's a win-win that showcases how automation can improve everyday experiences for everyone.

Automated Transportation Solutions

The world of transportation is also being transformed by automation. While fully self-driving cars are still on the horizon, many vehicles today already include automated features that improve safety and convenience. These systems use advanced technologies like sensors and artificial intelligence to assist the driver.

Features like adaptive cruise control, which automatically adjusts your speed to maintain a safe distance from the car ahead, are a form of automated transportation. Lane-keeping assist and automatic emergency braking are other examples that use automation to enhance safety on the road.

Beyond personal cars, automated systems are already common in public transit, such as automated trains in airports. As artificial intelligence and other advanced technologies continue to develop, we can expect to see even more sophisticated automated transportation solutions that promise to make travel safer and more efficient.

Benefits of Implementing Automation

Implementing automation offers a wide range of compelling advantages for businesses of all sizes. The benefits of automation go far beyond just speeding up production. They extend to improving productivity, enhancing workplace safety, and ensuring consistent quality control across the board.

By investing in automation, companies can optimize their operations, reduce costs, and gain a significant competitive advantage. These benefits ultimately lead to a more resilient and profitable business model. Let's break down some of the key advantages that make automation such a powerful tool for modern industries.

Enhancing Productivity and Output Quality

One of the most significant benefits of automation is a dramatic increase in productivity. Automated machines can operate 24/7 without breaks or fatigue, leading to a much higher output than what is possible with manual labor alone. This allows companies to meet growing customer demand and scale their operations effectively.

In addition to speed, automation also enhances output quality. Machines perform tasks with a high degree of precision and consistency, which minimizes errors and ensures that every product meets the same standards. This focus on product quality helps build a strong brand reputation and increases customer satisfaction.

By using automation solutions to handle production, businesses can achieve a level of efficiency and reliability that is difficult to match. The combination of higher productivity and superior product quality makes automation a powerful driver of business growth.

Cost Savings and Resource Optimization

While there is an initial investment, automation delivers substantial long-term cost savings. By streamlining processes and reducing errors, automation leads to lower production costs. Machines can perform tasks with minimal waste, which translates to better resource optimization and savings on raw materials.

Automation also helps reduce labor costs. By automating repetitive tasks, companies can optimize their workforce, assigning employees to more strategic roles. This doesn't necessarily mean cutting jobs, but rather reallocating human talent to areas where it adds more value.

Furthermore, automation minimizes costly downtime. Predictive maintenance, enabled by AI and sensors, can identify potential equipment failures before they happen, allowing for scheduled repairs instead of disruptive and expensive shutdowns. All these factors contribute to a more cost-effective and profitable operation.

Increased Safety for Workers

Improving workplace safety is one of the most important benefits of automation. Many industrial environments involve tasks that are dangerous for human workers, such as handling heavy materials, working with hazardous chemicals, or operating in extreme temperatures. Automation allows machines to take over these specific tasks.

By deploying robots and other automated systems in hazardous environments, companies can significantly reduce the risk of accidents and injuries. This protects human workers and creates a safer workplace for everyone. This is a crucial role for automation, especially in industries like manufacturing, mining, and construction.

This focus on safety not only prevents injuries but also improves employee morale. When workers feel safe and are freed from physically demanding or dangerous tasks, they can focus on more engaging and satisfying work. This contributes to a better overall employee experience and can help with retention.

Improved Consistency and Reliability

Consistency is key to delivering a high-quality product, and automation excels at it. Unlike manual labor, which can be prone to variability due to fatigue or human error, automated systems perform industrial processes the same way every single time. This unwavering consistency is fundamental to effective quality control.

Whether it's assembling a complex electronic device or applying a precise amount of paint, automation ensures that every unit is identical. This reliability helps manufacturers meet strict regulatory standards and uphold their commitment to product quality. Customers can trust that they will receive the same excellent product with every purchase.

This level of consistency also makes industrial processes more predictable and easier to manage. With fewer variations in the production line, it becomes simpler to identify bottlenecks, optimize workflows, and maintain a high level of efficiency across the entire operation.

Challenges and Considerations in Automation

While the benefits of automation are clear, implementing it is not without its challenges. Businesses must consider several factors before diving in, including the significant initial investment required for equipment and software. Without proper planning, these costs can be a major barrier for smaller companies.

Other important considerations include integrating new systems with existing infrastructure, managing the workforce transition, and addressing potential security concerns. Successfully navigating these challenges is crucial for a smooth and effective automation journey. Let's examine these potential hurdles in more detail.

Integration With Existing Systems

One of the biggest technical hurdles is the integration of new automation solutions with existing systems. Most companies can't afford to replace their entire infrastructure at once. Therefore, new automated technologies must be able to communicate and work seamlessly with legacy software and machinery.

This process can be complex, especially when dealing with older systems that weren't designed for modern connectivity. Poor integration can lead to data silos, inefficient workflows, and systems that don't perform as expected. Careful planning and choosing compatible automation solutions are essential to avoid these issues.

For example, when implementing business process automation, it's vital to ensure the new software can pull data from and push data to existing databases and applications. A phased approach to integration can help manage this complexity.

| Integration | Potential Solution |

|---|---|

| Incompatible Systems | Use middleware or APIs to connect different technologies |

| Data Silos | Implement a centralized data management platform. |

| Lack of Expertise | Partner with an experienced integration specialist. |

| Disruption to Operations | Plan a phased rollout during off-peak hours. |

Workforce Transition and Skill Requirements

A common concern about automation is its impact on jobs. The reality is that automation changes the nature of work rather than simply eliminating it. This requires a managed workforce transition to help employees adapt to new roles and skill requirements.

Instead of performing manual tasks, workers in an automated environment are needed to oversee, maintain, and optimize the automated systems. This shift demands new skills, particularly technical expertise in areas like robotics, programming, and data analysis. The focus moves from manual labor to leveraging human capabilities for problem-solving and strategic thinking.

Companies have a responsibility to support this transition by investing in training and upskilling programs for their employees. By helping workers develop the necessary technical expertise, businesses can ensure a smooth transition and empower their workforce for the future of work.

Addressing Security and Ethical Concerns

As automated systems become more connected, security becomes a critical concern. These systems can be vulnerable to cyber threats, which could disrupt operations or compromise sensitive data. Implementing robust security measures is essential to protect automated infrastructure from potential attacks.

Beyond security, there are also ethical concerns to consider. For example, the use of AI and data analytics in automation raises questions about data privacy and algorithmic bias. It's important to ensure that these systems are used responsibly and transparently, with clear guidelines on how data is collected and used.

Maintaining a level of human input and oversight is crucial for addressing these ethical challenges. While automation can handle many tasks, final decisions in sensitive areas should often remain in human hands to ensure accountability and fairness.

Sectors Most Impacted by Automation

The impact of automation is felt across various industries, but some sectors have been more profoundly transformed than others. The manufacturing industry has long been a leader in adopting automation, but its influence is rapidly expanding into other areas like healthcare, finance, and logistics.

These early adopters are leveraging automation solutions to gain a competitive edge and set new standards for efficiency and quality. Understanding where automation is making the biggest waves can provide insight into its future potential. Let’s explore some of the sectors most affected by this technological revolution.

Manufacturing and Industrial Operations

The manufacturing industry is arguably the sector most synonymous with automation. For decades, manufacturers have used industrial automation to streamline production lines, improve quality, and increase output. From automotive assembly to electronics production, automation is at the heart of modern manufacturing.

In this sector, automation solutions are used for a wide range of tasks, including welding, painting, assembly, and packaging. Robots and other automated systems handle these repetitive and physically demanding jobs with speed and precision, leading to significant gains in operational efficiency.

As technology advances, manufacturing is moving toward "smart factories," where every aspect of the operation is connected and optimized through automation. This deep integration allows for unprecedented levels of control and adaptability, solidifying automation's crucial role in the future of the manufacturing industry.

Healthcare Innovations

The healthcare sector is increasingly embracing automation to improve patient care and operational efficiency. While not as visible as in manufacturing, automation solutions are making a significant impact behind the scenes. This includes automating administrative tasks, managing patient records, and assisting in medical procedures.

Advanced technologies like robotic-assisted surgery allow surgeons to perform complex operations with greater precision and control. In laboratories, automated systems can process tests and analyze samples much faster than manual methods, leading to quicker diagnoses. Data analytics tools also help healthcare providers identify trends and improve treatment plans.

As the healthcare industry continues to face challenges like rising costs and staff shortages, automation offers a path toward a more efficient and effective system. These innovations are helping to reduce administrative burdens on medical staff, allowing them to focus more on direct patient care.

Financial Services Automation

The financial services industry has also been heavily impacted by automation, particularly through business process automation. Banks and other financial institutions are using automation solutions to handle a wide variety of tasks, from processing transactions to detecting fraudulent activity.

For example, algorithms can analyze thousands of transactions in real-time to flag suspicious patterns that might indicate fraud. Customer service is another area where automation has made inroads, with chatbots handling common inquiries and freeing up human agents for more complex issues.

Behind the scenes, automation is used for tasks like loan processing, account management, and regulatory compliance reporting. By automating these rule-based processes, financial institutions can improve accuracy, reduce costs, and provide faster service to their customers.

Skills Needed for Careers in Automation

As automation reshapes the workforce, the skill requirements for many jobs are also changing. To thrive in a world with more automation, workers need to develop a new set of capabilities. It's less about performing manual tasks and more about working alongside technology.

The most in-demand skills include technical expertise, strong problem-solving abilities, and a high degree of adaptability. Cultivating these skills will be essential for anyone looking to build a successful career in the field of automation or in any industry that uses it. Let’s explore these key competencies.

Technical Expertise and Training

A strong foundation of technical expertise is essential for working with automation systems. This includes understanding the principles of robotics, programming, and mechanics. People who can design, install, and maintain these systems are in high demand across many industries.

This doesn't mean everyone needs to be an engineer. Technicians who can troubleshoot and repair automated equipment on the factory floor are just as crucial. The specific technical expertise required will vary depending on the role, but a general understanding of how industrial automation works is a valuable asset.

Continuous training is also vital. As technology evolves, workers need to stay up-to-date on the latest automation systems and software. Companies that invest in ongoing training for their employees will be better equipped to leverage the full potential of their automated infrastructure.

Problem-Solving and Analytical Skills

With machines handling the routine tasks, the role of human workers shifts to oversight and optimization. This requires strong problem-solving and analytical skills. When an automated system encounters an issue, someone needs to be able to diagnose the problem and find a solution quickly to minimize downtime.

This involves analyzing data from the system to identify inefficiencies or potential improvements in the process automation workflow. Workers may need to interact with a human machine interface (HMI) to monitor performance, adjust settings, and interpret system feedback.

The ability to think critically and approach challenges systematically is a key human advantage that complements automation. People who can look at a complex system, understand how it works, and figure out how to make it better will be invaluable in an automated workplace.

Continuous Learning and Adaptability

The field of automation is constantly evolving due to rapid technological advances. What is state-of-the-art today may be outdated in a few years. Because of this, a mindset of continuous learning and adaptability is perhaps the most important skill of all.

Workers need to be open to change and willing to learn new skills throughout their careers. This adaptability will allow them to keep pace with new and advanced technologies as they are introduced. Those who embrace lifelong learning will be able to pivot and take on new roles as the demands of the workplace change.

This applies not just to technical skills but also to soft skills like collaboration and communication. As automation becomes more integrated, the ability to work effectively in teams that include both humans and machines will be crucial for success.

Automation and Artificial Intelligence: The Connection

The relationship between automation and artificial intelligence is one of the most powerful forces shaping technology today. While automation can exist without AI, the integration of artificial intelligence and machine learning is what unlocks its most advanced capabilities, leading to what is known as intelligent automation.

AI gives automation solutions the ability to perceive, reason, and learn, transforming them from simple task-doers into dynamic problem-solvers. This synergy is pushing the boundaries of what's possible and creating a new generation of smarter, more adaptable systems. Let's explore this critical connection.

How AI Expands Automation Capabilities

Artificial intelligence fundamentally expands what automation solutions can do. Traditional automation is based on pre-programmed rules and can only perform tasks exactly as instructed. AI, on the other hand, allows systems to handle variability and make decisions in real time.

Through machine learning, a subset of AI, automated systems can analyze data from their operations and learn from it. This enables them to improve their performance over time without human intervention. For example, an AI-powered robot can learn to identify and handle different types of objects, even if it hasn't been explicitly programmed for each one.

This ability to adapt and learn makes automation far more powerful and versatile. By leveraging these advanced technologies, businesses can automate more complex and dynamic processes that were previously beyond the reach of traditional automation.

Examples of AI-driven Process Automation

AI-driven automation is already being used in many practical applications across various industries. These examples of intelligent automation showcase how AI enhances process automation by adding a layer of intelligence and adaptability.

One key application is in predictive maintenance, where AI algorithms analyze sensor data from machinery to predict when a part is likely to fail. This allows companies to perform maintenance proactively, avoiding costly unplanned downtime. Another example is in computer vision, where AI helps robots "see" and understand their environment.

Here are a few more examples of how AI is used in process automation:

- In logistics, AI optimizes delivery routes in real time based on traffic and weather conditions.

- In customer service, natural language processing allows chatbots to understand and respond to complex customer queries.

- In manufacturing, AI-driven systems adjust production parameters to maintain quality, even when raw materials vary.

Future Outlook: AI and Automation Together

Looking ahead, the fusion of artificial intelligence and automation will continue to be one of the most significant future trends in technology. As AI capabilities become more sophisticated, automation solutions will become even smarter, more autonomous, and more integrated into our lives.

We can expect to see the rise of "cognitive automation," where systems can understand context, handle unstructured data, and even collaborate with humans on creative tasks. This will open up new possibilities for automation in fields that have traditionally relied heavily on human judgment, such as research and design.

For businesses, embracing this trend will be crucial for maintaining a competitive advantage. Companies that successfully combine AI and automation will be able to innovate faster, operate more efficiently, and deliver better products and services to their customers.

Conclusion

In conclusion, automation has become an integral part of modern life, driving efficiency and innovation across various sectors. By understanding the different types of automation systems and key technologies that power them, individuals and businesses can harness their benefits to enhance productivity, reduce costs, and improve safety. However, it is crucial to navigate the challenges associated with integration, workforce transition, and security concerns. As automation continues to evolve, embracing the skills required for this landscape will be essential. Stay curious and open to learning as you explore how automation can transform your personal and professional life. If you're interested in diving deeper into automation solutions tailored to your needs, don’t hesitate to reach out for a free consultation!

Frequently Asked Questions

What are some common examples of automation in the United States?

In the United States, common automation solutions include industrial automation in the automotive and consumer goods sectors, which streamlines the production process. In daily life, we see it in self-checkout kiosks, automated customer service chatbots, and the growing popularity of smart home devices that manage lighting and temperature.

What skills are important for working with automation systems?

Key skills for working with automation systems include technical expertise in robotics and programming, strong problem-solving and analytical skills to optimize processes, and adaptability to keep up with new technologies. A mindset of continuous learning is crucial for a successful career in this evolving field.

How does automation benefit both businesses and consumers?

The benefits of automation are widespread. For businesses, it increases productivity, leads to significant cost savings, and improves product quality. Consumers benefit from these improvements through lower prices, higher-quality goods, and enhanced experiences like faster and more convenient customer service.